A Carbon Steel Perforated Metal Sheet is a versatile material used in architecture, filtration, acoustics and industrial applications. This guide walks through the full manufacturing process — from raw material selection to post-production inspection — and highlights the essential quality checkpoints that ensure consistent, high-performance sheets.

1. Raw Material Selection

The first step is selecting the correct carbon steel coil or plate. Key considerations include carbon content, yield strength, thickness tolerance, and surface finish. Specify ASTM or EN standards where applicable and request mill test certificates (MTCs) to verify chemical and mechanical properties. Choosing the right grade reduces warping and improves punchability.

2. Plate Preparation and Leveling

Before perforation, sheets are flattened and leveled to remove coil set and internal stresses. Leveling machines and shot-blasting may be used to clean the surface and improve uniformity. Accurate leveling reduces burr formation and improves hole accuracy.

3. Tooling and Punching Methods

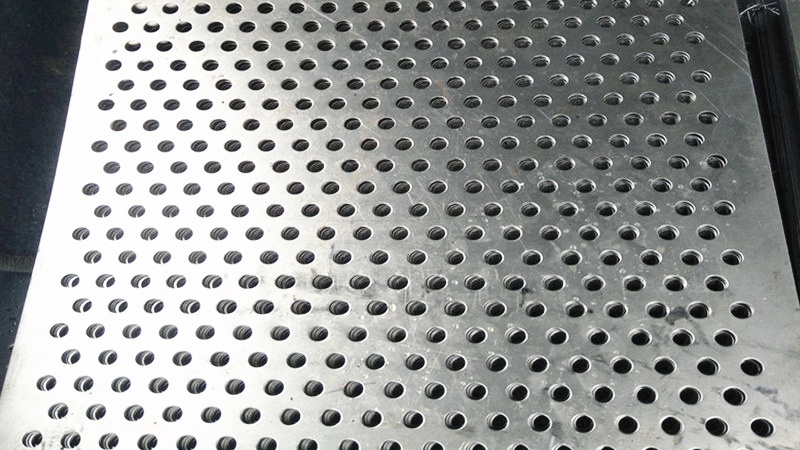

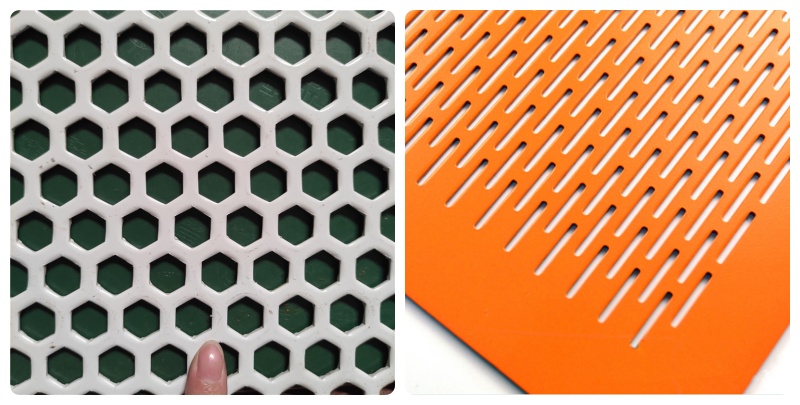

There are several punching and cutting methods: mechanical turret punching, CNC punching, and laser cutting.

- Turret punching is cost-effective for standard round, square and hex patterns.

- CNC punching allows custom layouts and mixed patterns.

- Laser cutting provides the cleanest edges for complex shapes.

Tooling selection matters: hardened punches and dies matched to material thickness extend tool life. Progressive punching and careful feed control reduce distortion and scrap.

4. Pattern Design and Nesting

Optimize the hole pattern to balance open area, structural integrity, and material yield. Proper nesting minimizes scrap and reduces cost. Consider minimum edge distances to avoid tear-out and ensure panels retain strength for handling and installation.

5. Deburring and Finishing

After perforation, deburring removes sharp edges and burrs caused by punching. Finishing options include sandblasting, pickling, galvanizing, powder coating, or painting depending on corrosion resistance and aesthetic requirements. For galvanized sheets, inspect coating thickness and uniformity.

6. Flattening and Stress Relief

Perforated sheets often require final flattening and stress relief to remove distortion from punching. Heat treatment or controlled bending can restore flatness. Final thickness checks should be performed after these steps.

7. Dimensional Inspection and Tolerances

Key dimensional checks include overall sheet size, hole diameter, pitch, concentricity, and edge squareness. Use calibrated verniers, optical comparators, or CMMs (coordinate measuring machines) for precision work. Record tolerances against customer specifications.

8. Mechanical Properties and Surface Tests

Perform hardness tests, tensile tests (when required), and surface adhesion tests for coatings. For applications where strength is critical, verify yield strength and elongation per the specified standard. For painted or coated sheets, perform salt spray tests and adhesion checks.

9. Open Area and Acoustic / Flow Performance

Measure open area percentage and verify that it matches design requirements for flow, filtration or acoustic performance. Use image analysis software or physical gauging to confirm hole size distribution and open area.

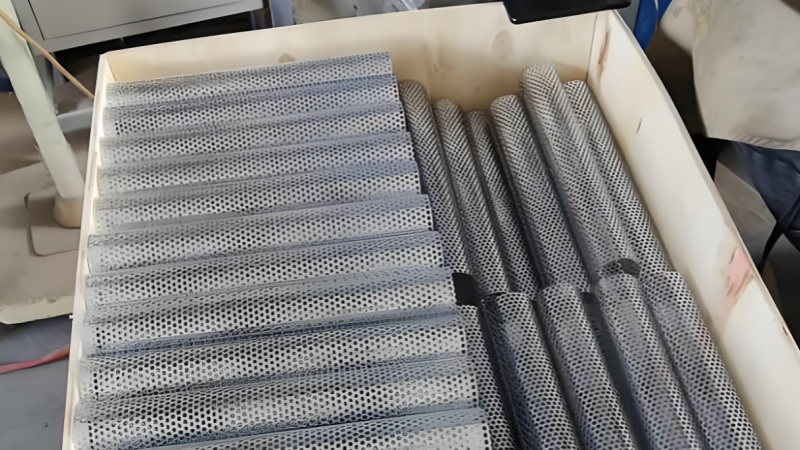

10. Visual Inspection and Packaging

Visual checks catch surface defects, coating issues, or pattern inconsistencies. Pack sheets with protective interleaving (e.g., kraft paper or plastic film) and secure them on pallets to prevent scratching during transport. Label batches clearly with traceability information.

11. Common Quality Issues and Remedies

- Burrs and ragged edges: adjust tooling clearance or replace worn punches.

- Distortion and warping: improve leveling, adjust feed rate, or apply stress-relief operations.

- Coating defects: ensure proper surface preparation and maintain coating bath parameters.

- Incorrect hole sizes: recalibrate punches or laser parameters and check material thickness variance.

12. Quality Management and Traceability

Implement a documented quality management system (QMS) with batch records, inspection checklists, and MTC archiving. Traceability from raw coil to finished sheet protects both manufacturer and customer and simplifies warranty claims.

13. Tips for Specifiers and Buyers

- Provide detailed drawings with hole pattern, material grade, and tolerance callouts.

- Request sample panels before full production runs for critical applications.

- Consider edge treatments and mounting holes as part of the manufacturing scope.

A consistent, well-documented manufacturing process combined with rigorous quality inspection is the foundation of reliable carbon steel perforated metal sheet production. By controlling material selection, tooling, finishing and inspection, manufacturers can deliver products that meet structural, aesthetic and functional requirements.