Precision Metal Perforation Solutions Expert

Based in Anping · Specialized in Custom Perforated Metal Sheets for Global Architectural and Industrial Projects

Anping Senchi Metal Wire Mesh Products Co., Ltd. focuses on the R&D and production of high‑performance perforated metal sheets, providing global customers with one‑stop customized services from solution design, precision punching, secondary processing to surface finishing.

Whether it is architectural facades, interior acoustic spaces, industrial filtration, or anti‑slip platforms, we rely on years of practical experience and stable quality to help customers turn drawings and ideas into finished, workable products.

Company Overview

Anping Senchi Metal Wire Mesh Products Co., Ltd. is located in the well‑known “Hometown of Wire Mesh” in China — the East Industrial Park of Anping County, Hengshui City, Hebei Province. We are a manufacturing factory specialized in the design and production of perforated metal sheets.

Since our establishment in 2017, we have been deeply involved in the perforated metal segment. Our products have been exported to Europe, North America, the Middle East, Southeast Asia, and many other countries and regions, providing long‑term, stable supply and technical support for construction contractors, design companies, equipment manufacturers, and metal fabricators.

Unlike ordinary trading companies, Senchi is a real manufacturing factory with our own workshops and processing equipment. We clearly understand that every step — from raw material selection to punching accuracy, from sheet flatness to surface treatment — will directly affect installation on site and service life. Therefore, all our investment in processes, equipment, and quality control revolves around one goal: to ensure that customers can use our products with confidence.

Key Facts:

Year Established: 2017

Location: East Industrial Park, Anping County, Hengshui City, Hebei Province, China

Factory Type: Manufacturing factory, supporting OEM and custom production based on drawings or samples

Number of Employees: About 40–50 people

Main Markets: Overseas markets including Europe, North America, the Middle East, Southeast Asia, etc.

Production and Technical Capabilities

Punching and Forming Capabilities

This is part of our plant’s computer-controlled punching equipment for making perforated steel sheets.

Senchi Metal specializes in perforation and forming of various metal sheets, with processing capabilities from thin sheet to thick plate:

- Punching range: sheet thickness approx. 0.1–30 mm (can be adjusted according to actual capability)

- Sheet size: standard width up to 1500 mm, length up to 6000 mm (coil supply available for thin material)

- Hole types:

- Round, square, oblong (slot), and oval holes

- Triangle, hexagonal, and diamond holes

- Cross holes, embossed anti‑slip holes, raised anti‑slip patterns

- Various custom shapes according to customer drawings

- Accuracy control: based on specific processes, we ensure that hole diameter, tolerance, and pitch meet design requirements. For projects with higher precision demands, we can provide sample trials for confirmation.

We can undertake both large‑volume production of standard specifications and flexible custom production for small batches, complex hole patterns, or special sheet shapes.

Secondary Processing and Value‑Added Services

After perforation and leveling are completed, perforated metal sheets can be bent or folded according to requirements. Perforated metal sheets that have undergone edge folding treatment have greater strength.

For perforated metal sheet products with particularly strict requirements on frame dimensions and diagonal tolerance, laser cutting can be used for final sizing after perforation and leveling are completed. This allows for more precise control over external dimensions.

After perforation, we can carry out further processing according to project needs to help customers reduce outsourcing steps and shorten overall lead time:

- Cutting: shearing, punching, CNC/laser cutting of complex outer shapes

- Forming: bending, rolling, flanging, ribbing, deep drawing, etc.

- Welding and assembly: spot welding, structural welding, frame welding, and basic component assembly

- Surface treatment:

- Carbon steel: hot‑dip galvanizing, electro‑galvanizing, powder coating, painting, etc.

- Stainless steel: brushing, polishing, etc.

- Aluminum and aluminum alloys: anodizing, powder coating (including outdoor weather‑resistant powder), etc.

For projects with specific performance requirements (such as sound absorption, anti‑slip, or wear resistance), we can also recommend suitable materials and surface finishing solutions based on the intended use.

Engineering and Technical Support

Our engineering team has long been involved in architectural, acoustic, and industrial projects and has extensive practical experience in the application of perforated metal sheets. We can provide support at the early stages of projects, including:

- Recommending appropriate material and thickness based on usage scenarios (indoor/outdoor, corrosive environment or not, load‑bearing or non‑load‑bearing)

- Suggesting reasonable hole diameter, pitch, and open area according to acoustic, ventilation, or shading requirements

- Conducting manufacturability reviews of DXF/DWG/PDF drawings provided by customers and offering structural optimization suggestions

- Producing samples for projects and ensuring consistency in mass production after sample approval

We understand that not every customer is familiar with all the design details of perforated metal sheets. That is why Senchi prefers to bring our experience into the design stage, helping customers avoid potential machining and installation issues as early as the drawing phase.

Main Products and Application Fields

Main Product Types (by Material)

Carbon Steel Perforated Sheet

Carbon steel perforated sheets can be produced from hot‑rolled or cold‑rolled steel and are suitable for applications with higher structural load requirements or where welding and galvanizing are needed, such as industrial platforms, equipment guards, and filter screens.

Stainless Steel Perforated Sheet (304 / 316, etc.)

Suitable for environments with high requirements for corrosion resistance and hygiene, such as food processing equipment, chemical equipment, and outdoor decorative elements.

Aluminum Perforated Sheet (1000 / 3000 / 5000 / 6000 series)

Featuring light weight, good corrosion resistance, and easy formability, aluminum perforated sheets are widely used in building facades, ceilings, acoustic panels, and interior decoration.

Galvanized Perforated Sheet

Combining the strength of carbon steel with the corrosion resistance of zinc coating, galvanized perforated sheets are commonly used for outdoor fences, protective screens, and ventilation louvers. Zinc coating thickness can be selected from 40 g/m² to 275 g/m². For products requiring higher corrosion resistance, hot‑dip galvanizing can be performed after perforation.

High‑Manganese Wear‑Resistant Perforated Sheet

Used in heavy wear and impact conditions, such as mining screens and wear‑resistant liners.

Typical Application Fields

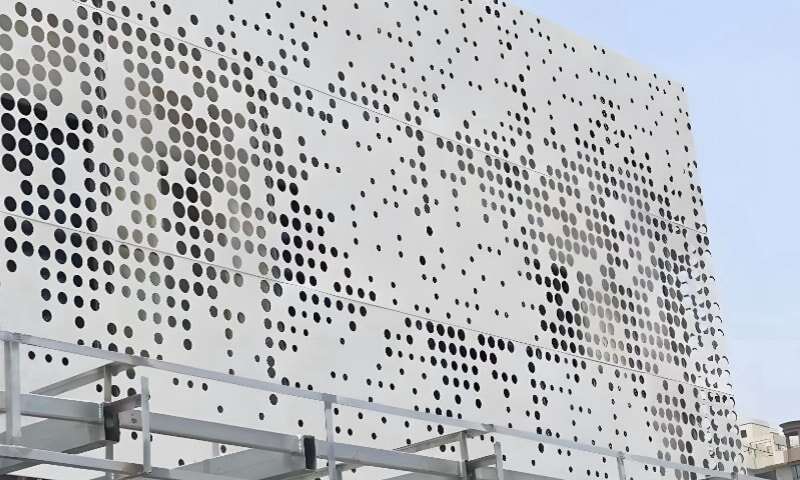

Architectural Decoration and Facade Systems

Perforated aluminum facade panels, cladding panels, sunshades, stair treads, and guardrails.

Acoustics and Sound Absorption

Perforated acoustic panels for cinemas, concert halls, KTVs, recording studios, and office spaces, used together with acoustic materials to enhance sound performance.

Industrial Filtration and Ventilation Systems

Filter screens, air intake and exhaust grilles, equipment guards, and machine safety partitions.

Anti‑Slip and Safety Platforms

Anti‑slip walkway plates, equipment maintenance platforms, and treads for areas requiring slip resistance.

Furniture and Interior Fit‑Out

Cabinet doors, partitions, lighting decorative panels, display shelving, and more.

Public Spaces and Landscape Facilities

Ceilings and wall cladding for subway stations, airports, and railway stations, as well as city sculpture cladding panels and landscape fences.

Quality Management and Process Control

In perforated metal projects, issues such as dimensional deviation, sheet deformation, and uneven coating can directly affect project schedules and service life.

To address this, and without over‑marketing ourselves, we rely on solid process control to ensure product quality:

Raw Material Control

We maintain stable procurement relationships with long‑term steel mills and material suppliers. Material grades, thickness tolerances, and surface conditions are strictly checked. When necessary, we can provide material composition test reports (third‑party testing can be arranged according to customer requirements).

Production Process Control

Key parameters such as hole size, pitch, and sheet flatness are subject to patrol inspection and sampling. For large‑volume or high‑requirement projects, we carry out trial production of samples before mass production, and only proceed after customer approval.

Flattening and Post‑Processing

Sheets that may develop internal stress or deformation after punching are leveled. Combined with subsequent processing (bending, welding, and surface treatment), we perform additional checks to ensure that final flatness meets installation requirements.

Final Inspection and Packaging

Each batch is inspected for appearance, dimensions, tolerances, and quantity prior to shipment. For products with surfaces that are easily scratched, we use reinforced packaging (such as protective film, soft padding, wooden cases, or reinforced pallets) to ensure suitability for sea, land, or air transportation.

Typical Projects and Application Experience

Case 1: Perforated Aluminum Facade for a Commercial Building in Europe

Location: A shopping mall in a European city

Product: 3.0 mm thick 3003 aluminum alloy perforated panels, with round holes and laser‑cut special outer contours

Application: Exterior facade decoration and sunshading

Our Work:

- Adjusted open area and sheet thickness based on the architect’s initial concept to balance visual effect and wind load requirements

- Provided samples for confirmation by the owner and design team

- Organized batch production and zone‑based packaging by floor and area to facilitate on‑site installation management

Case 2: Perforated Acoustic Ceiling Panels for an Airport Departure Hall in the Middle East

Location: An international airport in the Middle East

Product: 0.8 mm thick aluminum perforated acoustic panels with backing acoustic materials

Application: Acoustic treatment for departure hall ceilings

Our Work:

- Recommended suitable hole diameter and open area according to the acoustic consultant’s target values

- Coordinated panel dimensions with the ceiling suspension system to minimize on‑site cutting

- Provided samples and necessary coating tests to ensure long‑term color stability and durability

Case 3: Anti‑Slip Maintenance Platforms for a Chemical Plant in Southeast Asia

Location: A chemical project in Southeast Asia

Product: Perforated Safety Grating

Application: Equipment maintenance platforms and walkways

Our Work:

- Designed anti‑slip patterns and sheet thickness according to the owner’s safety standards

- Produced pre‑formed platform panels based on on‑site dimensions to reduce welding and cutting on site

- Focused on edge flanging and stiffener layout to improve overall load capacity and service life

Through these projects, we have accumulated extensive experience in material selection and structural design for different environments (such as coastal, high‑temperature, high‑humidity, and highly corrosive conditions) and apply this experience to optimize solutions in subsequent projects.

Customer Collaboration and Service Commitment

We understand that for overseas customers choosing a perforated sheet supplier in China, the key concerns are often: smooth communication, reliable lead time, stable quality, and timely response when issues arise.

Based on years of cooperation experience, we make the following commitments:

Rapid Response

- On working days, we usually respond to emails or messages within 2 hours

- For inquiries with clear parameters, we can typically provide detailed quotations and lead time estimates within 12–24 hours

Technical Support

- Engineers participate in early‑stage solution discussions, helping to determine material, thickness, hole pattern, and open area

- We conduct manufacturability evaluations of customer drawings and provide optimization suggestions to reduce processing costs and installation difficulty

Samples and Trial Production

- We support small‑batch sample production for on‑site trial installation, owner approval, or performance testing

- Before mass production, we can use samples or trial runs to finalize the process parameters

Transparent Lead Time and Progress

- Typical lead time for regular batch orders is 10–25 working days (depending on complexity and quantity)

- During order execution, we provide timely updates on production progress and loading schedules to help customers coordinate their construction plans

After‑Sales and Issue Resolution

- If any product cannot be installed or used properly due to manufacturing quality issues, we will actively help analyze the cause and propose rework, replacement, or other feasible solutions

- We value long‑term cooperation more than a single order

We have already supplied perforated sheet products and services to customers in many countries and regions, and many of them have become long‑term partners. Their feedback and repeat orders are what drive us to continuously improve.

Team and Corporate Culture

Senchi is not a “huge” factory, but it is a highly focused one. Our team consists of frontline workers, process engineers, quality inspectors, international sales staff, and logistics support personnel — each role is directly linked to product quality and customer experience.

We believe that “every hole reflects both craftsmanship and responsibility.” From tool design and punching production to leveling and packaging, every step must be taken seriously.

We encourage frequent communication between engineers and frontline technicians so that real processing experience can be fed back into drawing and process optimization.

We also encourage sales staff to deeply understand processes and on‑site conditions, so that they are not just “messengers” but true project coordinators who can help customers solve problems.

Although we have not yet documented every story, every real‑scene video and every workshop photo you see on our website is part of our daily work — not a staged showroom. We hope these authentic snapshots help you better understand who we are, what we do, and how we do it.

Contact Us for Customized Solutions and Quotations

If you are looking for a suitable perforated metal sheet supplier for your project, or if you want to optimize an existing design, you are welcome to send us your drawings and basic requirements. We will provide targeted recommendations and quotations based on your actual application.

Contact Information:

Email: info@perfsheet.com

Mobile / WhatsApp: +86 131 6555 5855

Address: East Industrial Park, Anping County, Hengshui City, Hebei Province, China

We usually reply within 12–24 hours.

To view detailed inquiry guidelines and submit an online form, please visit our “Contact Us” page.