Q1: What is the minimum order quantity (MOQ) for Carbon Steel Perforated Metal Sheet?

A1: Our Carbon Steel Perforated Metal Sheet has no strict MOQ. We accept both small trial orders and large bulk purchases, making it easy for customers to test samples before mass production.

Q2: How long is the lead time for Carbon Steel Perforated Metal Sheet?

A2: Standard sizes of Carbon Steel Perforated Metal Sheet are usually in stock and can be shipped within a few days. For customized sizes or special hole patterns, production typically takes 7–15 working days depending on order quantity.

Q3: Can you provide samples of Carbon Steel Metal Perforated Sheet before bulk orders?

A3: Yes, we can provide Carbon Steel Perforated Metal Sheet samples for quality confirmation. Customers can check the material, hole accuracy, and surface finish before proceeding with mass production.

Q4: What surface treatments are available for Carbon Steel Perforated Metal Sheet?

A4: Our Carbon Steel Perforated Metal Sheet can be treated with galvanizing, hot-dip galvanizing, powder coating, or painting. These treatments enhance corrosion resistance and extend product lifespan.

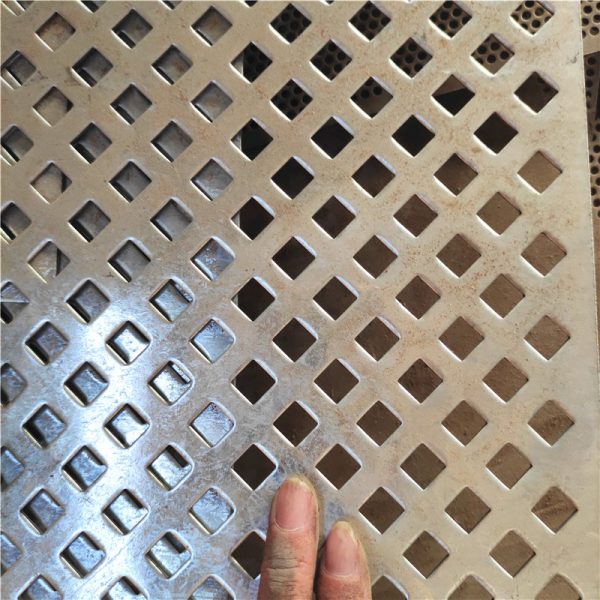

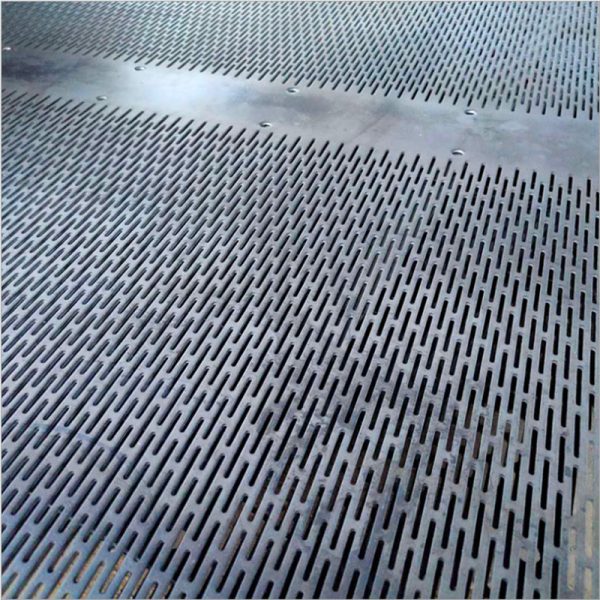

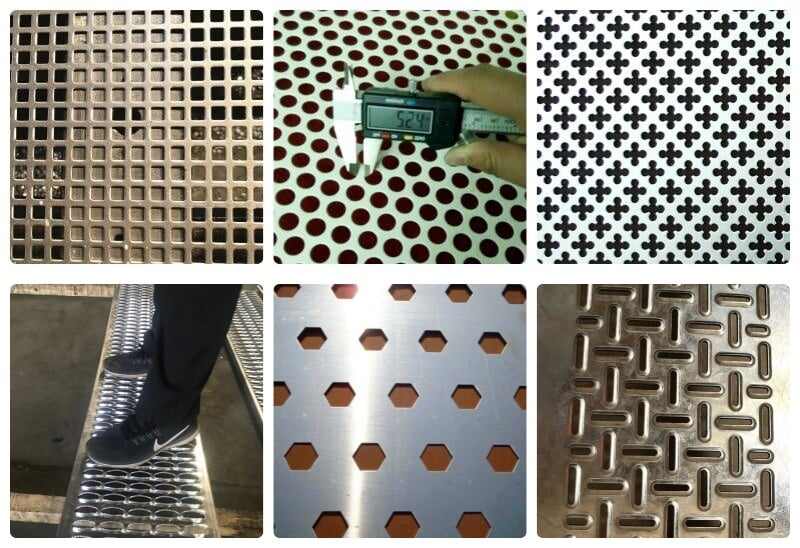

Q5: Do you offer customization for Carbon Steel Perforated Metal Sheet?

A5: Absolutely. We offer full customization for Carbon Steel Perforated Metal Sheet, including sheet dimensions, hole type, hole size, bending, welding, rolling, and laser cutting according to customer drawings.

Q6: Which industries commonly use Carbon Steel Perforated Metal Sheet?

A6: Carbon Steel Perforated Metal Sheet is widely used in construction (facade cladding, ceilings), industrial equipment (machine guards, filters), transportation (noise barriers), and agriculture (grain sieving, livestock protection).

Q7: Why should I choose your factory for Carbon Steel Perforated Metal Sheet?

A7: We are a direct factory specializing in Carbon Steel Perforated Metal Sheet, offering stable quality, competitive pricing, fast delivery, and one-stop processing services including punching, laser cutting, welding, and surface finishing.

Q8: What’s the difference between “perforated steel sheet” and “perforated carbon steel plate”?

A8: In many markets, “sheet” usually refers to thinner gauge, while “plate” often implies heavier thickness. We manufacture both—tell us thickness and application.

Q9: Can you produce perforated steel in coils?

A9: Yes. Thin-gauge material can be supplied in coils (length customizable), and we can also level and cut-to-length if needed.

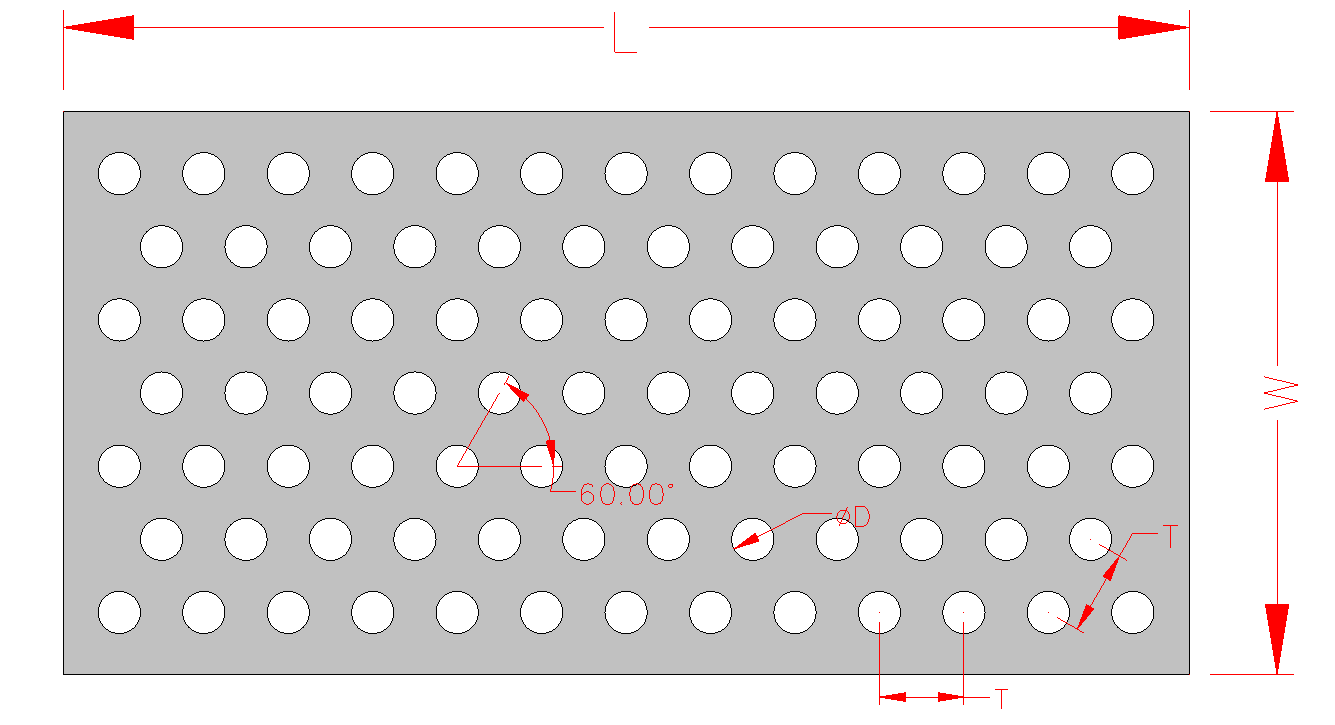

Q10: What hole layout options do you offer (staggered vs straight)?

A10: Both are available. A common layout is 60° staggered for round holes, and we also support straight-line patterns.

Q11: Can you help optimize open area for airflow or filtration?

A11: Yes—share your target airflow/filtration goals and constraints; we’ll recommend hole diameter/pitch/open area combinations.

Q12: Do you provide material certificates and inspection reports?

A12: Yes, material certificates can be provided; inspection photos/measurements are available on request.