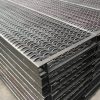

Grip Strut safety grating is a one-piece, anti-slip metal plank designed to provide secure foot traction, drainage and long service life in industrial and commercial environments. Manufactured by stamping/pressing or roll-forming, Grip Strut features toothed/serrated ribs (sometimes described as “crocodile” or “alligator” mouth profile) that create high traction underfoot while allowing dirt, debris and liquids to pass through.

This product is commonly used as stair treads, walkway planks, catwalks, platform flooring, vehicle step treads and maintenance access decks where slip resistance, strength and low maintenance are required.

Key selling points / benefits

-

High slip resistance — serrated ribs + open profile deliver secure footing in wet, oily or icy conditions.

-

Self-draining & debris shedding — openings allow liquids and small solids to pass; reduces ice buildup.

-

Low maintenance & long life — available in corrosion-resistant finishes (galvanized, stainless, anodized).

-

Structural strength — spans moderate distances with good load capacity when supported correctly.

-

Easy to install & retrofit — standard plank widths and lengths with pre-drilled or on-site fastening options.

-

Customizable — material, thickness, length, edge treatment and hole patterns can be tailored to project needs.

Typical applications

-

Industrial stairs and stair treads

-

Walkways, catwalks and mezzanines

-

Offshore platforms and marine walkways

-

Construction site temporary access

-

Transportation — truck and rail steps, vehicle platforms

-

Public works — pedestrian ramps and utility access points

-

Food & beverage and chemical plants (with appropriate materials/finishes)

Materials & common finishes

-

Carbon steel (mild steel): economical, strong; usually supplied with hot-dip galvanizing for corrosion protection.

-

Stainless steel (304 / 316): for corrosive and hygienic environments (316 preferred for marine/saline exposure).

-

Aluminum (6000-series): lightweight, corrosion-resistant, easy to handle — ideal where weight is a concern.

-

Finishes: Hot-dip galvanize (HDG), electro-galvanize, powder coat, anodize (for aluminum) or plain bare metal (for temporary or painted installations).

Typical sizes & dimensions (examples — customizable)

Note: these are typical ranges. We manufacture custom widths and lengths to order.

-

Standard plank widths: 50 mm / 75 mm / 100 mm / 150 mm / 200 mm / 300 mm (or metric equivalents)

-

Overall standard tread widths (stair treads): 250 mm – 400 mm (commonly 300 mm)

-

Standard lengths: 500 mm — 3,000 mm (cut to any length on order)

-

Thickness / gauge: 1.5 mm — 4.0 mm (plate thickness or nominal sheet gauge depends on material & load)

-

Edge styles: square cut, folded nosing (anti-trip), welded back plate for extra rigidity, punched/drilled edges for fasteners

Mechanical & safety considerations

-

Span & support: Grip Strut performs best when supported at recommended intervals; unsupported spans reduce load capacity. Provide project-specific span tables when required.

-

Fastening: countersunk bolts, carriage bolts, rivets or welding — pre-drilled holes and tapped options available. Use non-corrosive fasteners for corrosive environments.

-

Slip performance: serrated profile increases friction; select material/finish appropriate for environment to maintain anti-slip performance over time.

-

Edge treatment / nosing: folded or bull-nosed edges reduce trip hazard and increase rigidity for stair applications.

Comparison with similar products

-

Diamond plate / tread plate: raised pattern solid plate — good for light duty and cosmetic uses, but generally provides less drainage and may be less slip-resistant when wet than Grip Strut.

-

Expanded metal grating: open, highly rigid — very good for drainage and heavy loads but different surface feel; may be harder on footwear depending on mesh size.

-

Perforated plate: more solid than Grip Strut; perforations provide drainage but may clog more easily and typically offer lower bite/tracking than serrated treads.

Why choose our Grip Strut safety grating

-

In-house fabrication: custom cut, punch and finish to your project requirements.

-

Quality control: dimensional inspection, finish checks and optional certificates.

-

Project experience: supply for industrial plants, marine platforms and commercial facilities.

-

Global shipping & packaging: export packaging, bundling and labeling for international delivery.

Order / Request a quote: Contact us with your project details (material, plank width, thickness, length, finish and quantity) or upload drawings. For technical inquiries request our span/load table and mounting recommendations.

Email: info@perfsheet.com

Factory workshop

Factory workshop Factory workshop

Factory workshop Raw materials

Raw materials Raw materials

Raw materials