Why galvanizing helps perforated metal resist corrosion

Galvanizing deposits a zinc layer onto the steel surface that acts as both a physical barrier and a sacrificial anode. When the zinc is intact it prevents moisture and oxygen from reaching the steel; if the coating is scratched, the zinc corrodes preferentially and protects the underlying steel.

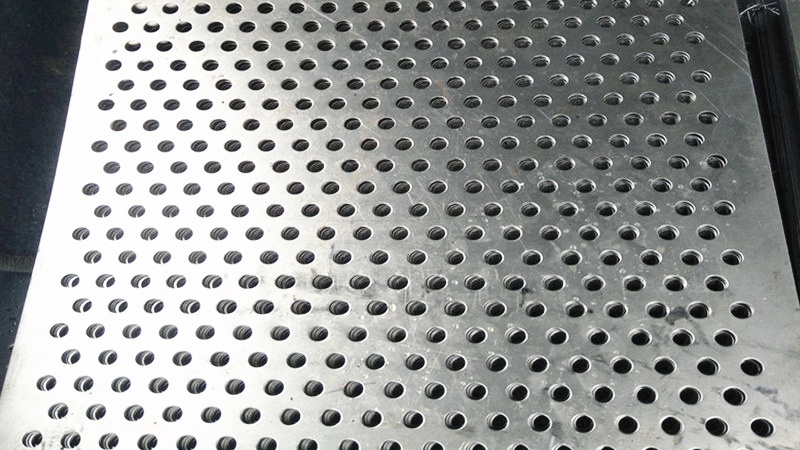

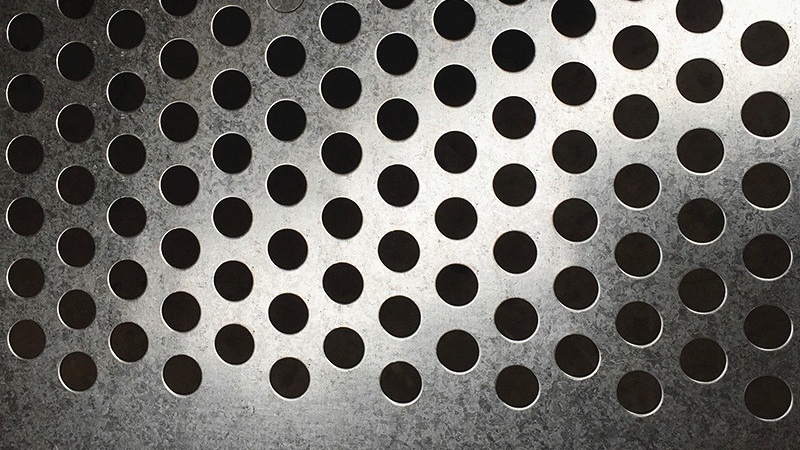

A Galvanized perforated metal sheet benefits from this protection despite having many cut edges (holes) because both the flat faces and the hole edges receive zinc coverage in modern galvanizing processes. The result is a perforated product with uniform protection across faces and edges — critical for long-term outdoor and industrial use.

Galvanizing methods and what they mean for perforated panels

There are two common galvanizing approaches used for perforated metal:

- Hot-dip galvanizing (HDG) — the sheet is dipped in molten zinc creating a metallurgical bond and relatively thick coating. This is the most durable option for heavy-duty outdoor exposure and coastal applications.

- Electro-galvanizing — a thinner, more uniform zinc layer applied electrically; good where appearance and tight tolerances matter but less sacrificial protection than HDG.

When specifying a Galvanized perforated metal sheet, choose HDG for long service life in industrial or coastal environments and electro-galvanized for indoor architectural use where surface finish matters.

How galvanized perforated sheets compare to stainless and aluminum

- Cost: Galvanized perforated metal sheet typically offers lower upfront cost than stainless steel perforated metal sheet while delivering excellent corrosion resistance for many applications.

- Durability: Stainless outlasts galvanizing in extremely aggressive chemistries (strong acids, chlorides) but for general outdoor, municipal, and architectural use, galvanized perforated panels are cost-effective and durable.

- Weight and formability: Aluminum perforated metal sheet is lighter and easier to form but can suffer galvanic corrosion against certain metals; galvanized perforated metal sheet balances strength and cost.

When weight is not the deciding factor and chloride exposure is moderate, galvanized perforated metal sheet is often the smartest value choice.

Typical application scenarios

Below are realistic, project-level examples where a Galvanized perforated metal sheet is an excellent choice:

- Architectural facades & sunshades: Durable finish, consistent edge protection, economical for large panels.

- HVAC and screening: Good airflow with corrosion resistance in mechanical rooms and external installations.

- Noise control & enclosures: Makes long-lasting acoustical screens and machine guards.

- Filtration, sieving & industrial processing: When zinc contamination is acceptable, galvanized perforated metal sheets perform well in light processing.

- Walkways, stair treads & anti-slip surfaces: Perforated anti-slip plating with galvanizing reduces corrosion on outdoor stairs and platforms.

- Coastal and municipal projects: With HDG, the sacrificial zinc layer extends life near sea spray (though stainless may still be preferred very near the surf).

Design, selection and practical tips

- Hole pattern & open area: Select round, square, or slot perforations based on strength, visual effect, and drainage. Larger open area increases exposure but also airflow and weight savings.

- Thickness & coating class: For outdoor decks and heavy loading choose thicker base steel and HDG with a specified coating weight (e.g., 275 g/m² or higher).

- Edge treatment: If edges are post-formed or finished in the shop, request re-galvanizing or additional zinc touch-up to maintain edge protection on a Galvanized perforated metal sheet. [Internal link: /services/custom-finishing]

- Fastening & welding: Use compatible fasteners (zinc-coated or stainless) to avoid galvanic issues; welding may require post-weld coating.

Maintenance & longevity

Routine rinsing to remove salt and airborne chlorides, occasional inspection of seams and fasteners, and spot-touching with zinc-rich paint extend life. For most urban and rural installations, a well-specified Galvanized perforated metal sheet will deliver 15–30 years of service before any major intervention is needed.

A correctly specified Galvanized perforated metal sheet offers a practical blend of corrosion protection, structural performance, and cost efficiency across architectural, industrial, and infrastructure applications. If your project needs long-lasting perforated panels without the premium of stainless steel, galvanized options are often the most pragmatic solution.

For sample panels, coating certificates, or a custom quotation, contact our sales team and request a datasheet for galvanized perforated options.