By Material

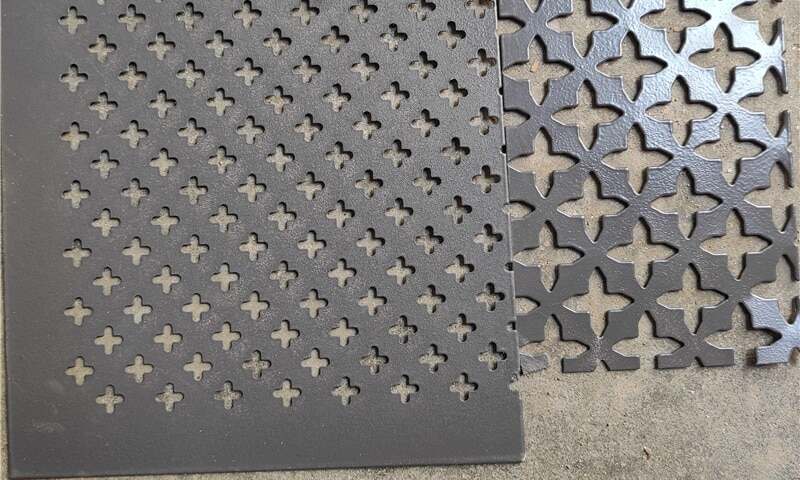

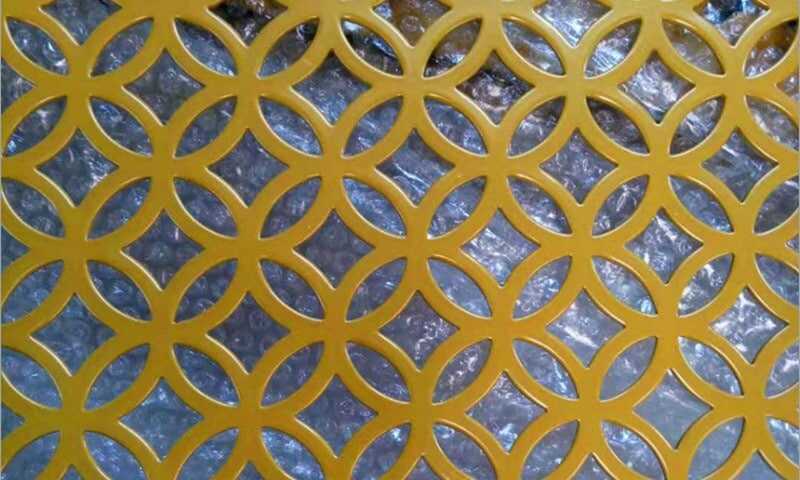

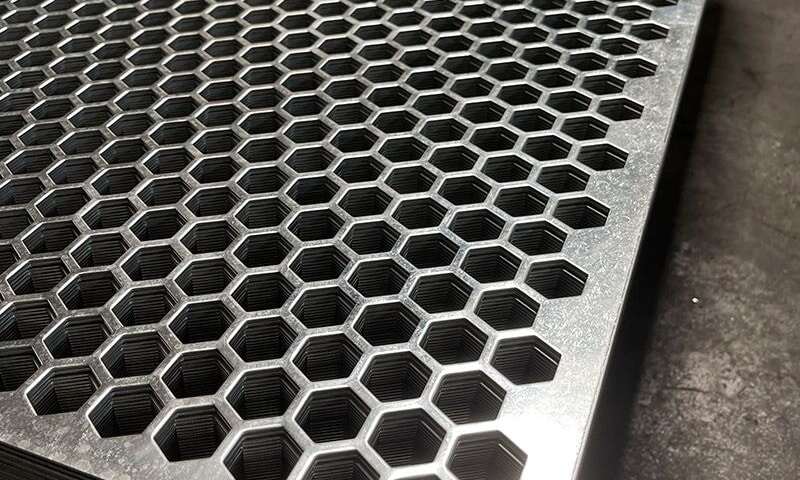

By Hole Shape

Contact Us

- Mobile Number: +86 13165555855

- E-mail:info@perfsheet.com

- Whatsapp:+86 13165555855

-

Business Hours:

Weekdays: 08:00-18:00 GMT+8 -

Address: Anping County East Industrial Park,

Hengshui City, Hebei Province, China