5052 Aluminum: The “Workhorse” Alloy We Trust for Tough Environments

When customers ask us to build Aluminum Round Hole Perforated Screens for coastal projects or equipment protection, we often recommend 5052 aluminum—not because it’s trendy, but because it performs consistently when conditions get harsh.

In real industrial use, perforated sheets don’t just “sit there.” They see vibration, repeated loading, temperature swings, salt-laden air, washdowns, and occasional impacts. In these scenarios, 5052 tends to hold up better than many common aluminum options—especially when fatigue strength and corrosion resistance matter as much as appearance.

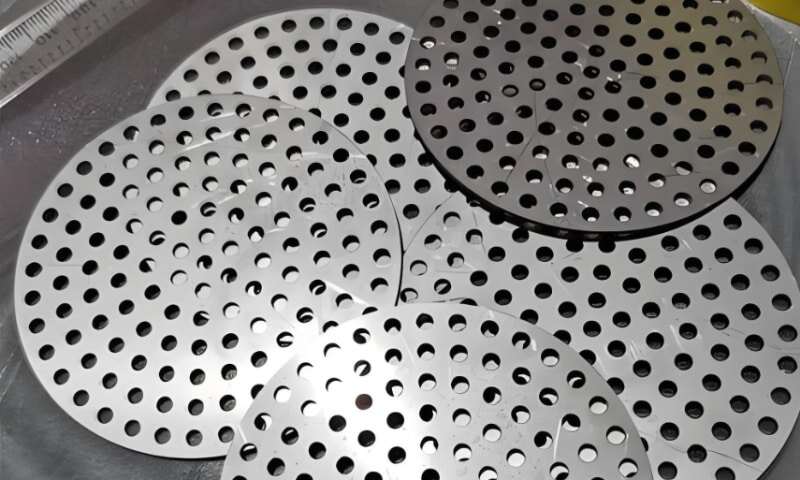

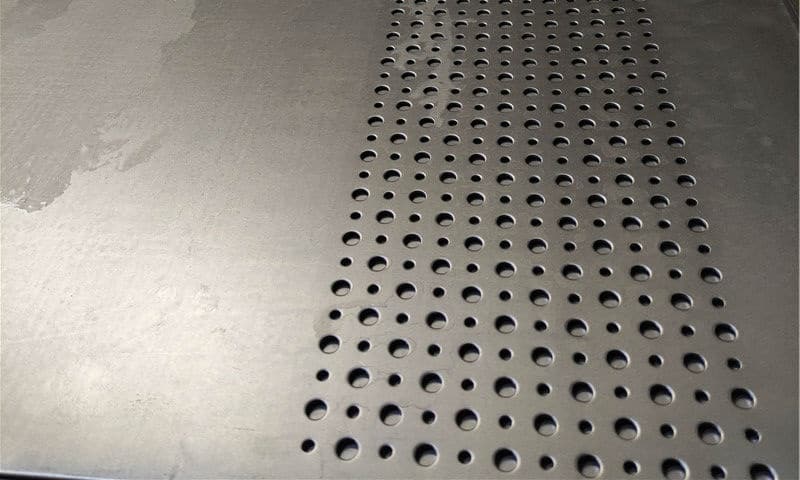

Round Hole Perforated Metal Sheets

Custom perforated metal sheets with precise hole patterns in various materials: stainless steel, aluminum, galvanized steel, carbon steel, copper, brass, and plastic. Durable and corrosion-resistant.

Perfect for architectural screens, machinery guards, acoustic panels, and decorative elements. Factory-direct pricing with cutting/bending services. Request quote or sample today.

What Makes 5052 Different from “Standard” Aluminum Sheet

5052 is an aluminum-magnesium alloy known for its balance of:

- Strong resistance to corrosion (including marine and salty air exposure)

- Good fatigue performance under vibration and repeated loading

- Excellent formability for bends, flanges, and frames

- Reliable weldability for guards, housings, and assemblies

That combination is a big reason why 5052 is widely used in marine components, transportation, and machine guarding—exactly the same environments where Aluminum Round Hole Perforated Screens are expected to last.

High Fatigue Strength: Why It Matters in Heavy Machinery Guarding

Fatigue failure is different from “one-time overload.” A sheet might survive a single impact but crack later due to continuous vibration or cyclical stress at mounting points.

For equipment guards—think crushers, conveyors, vibrating screens, fans, HVAC intakes near industrial plants—perforated metal can experience:

- Constant vibration from motors and rotating parts

- Pulsing airflow loads (pressure changes)

- Repeated micro-flexing around fasteners

- Occasional tool or debris contact

In these situations, 5052’s fatigue behavior is a practical advantage. When we design Aluminum Round Hole Perforated Screens for heavy-duty guarding, we pay special attention to the “fatigue hotspots”:

- Fastener rows near corners

- Cutouts (handles, access windows, inspection ports)

- Bends where the sheet transitions into a frame

- Areas with high open-area patterns that reduce ligament width

Our design approach for fatigue-prone applications

- Avoid extremely thin ligament widths (distance between holes) near mounting edges

- Use reinforced borders (unperforated margins) when required

- Recommend appropriate thickness based on span and vibration level

- Align hole pattern with load direction when possible

The alloy choice is only one part. A fatigue-resistant design is what turns good material into long service life.

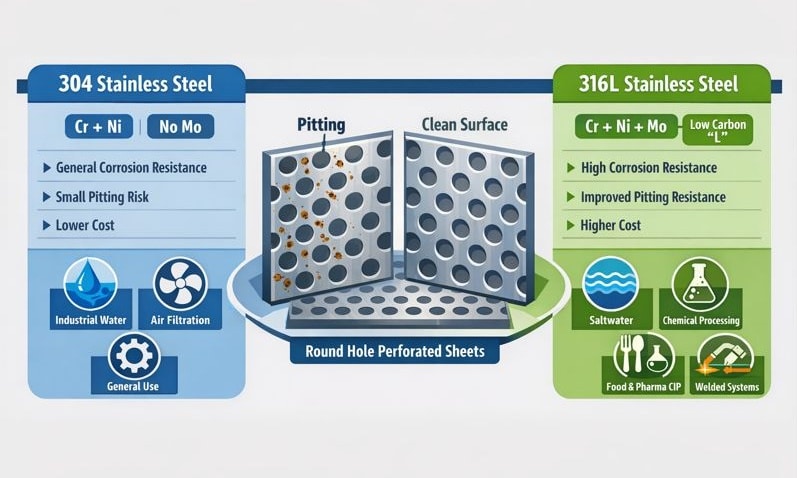

Marine & Coastal Performance: 5052 Helps Fight Real-World Corrosion

In marine and near-marine environments, corrosion isn’t always dramatic at first—it often starts as dulling, pitting, staining, and accelerated wear around joints.

5052 is valued because it offers strong resistance in:

- Salt spray and ocean air exposure

- Coastal construction sites

- Ports, docks, and shipyard facilities

- Outdoor equipment near de-icing salts and chemical mist

For customers using Aluminum Round Hole Perforated Screens in these areas, we typically discuss the full system—not just the sheet:

- Alloy + temper selection (common choices are tempers that balance strength and formability)

- Surface finish (mill finish, brushed, anodized, or coated depending on environment)

- Fastener compatibility (to reduce galvanic corrosion risks)

- Drainage and airflow design (to avoid trapped moisture behind panels)

A practical note on “marine resistant”

No aluminum is magically immune in every condition. Long life comes from matching the alloy with the right finish and proper installation details. 5052 gives you a strong baseline—then finishing and design do the rest.

Why Round Hole Patterns Work So Well in Industrial Screens

Round holes aren’t just common because they’re easy to manufacture. In many industrial and architectural uses, round holes offer a reliable mix of:

- Balanced strength across directions

- Predictable open area and airflow behavior

- Cleaner stress distribution versus many sharp-corner patterns

- Easy cleaning for filters, guards, and enclosures

That’s why many customers standardize on Aluminum Round Hole Perforated Screens when they want repeatable performance across multiple projects.

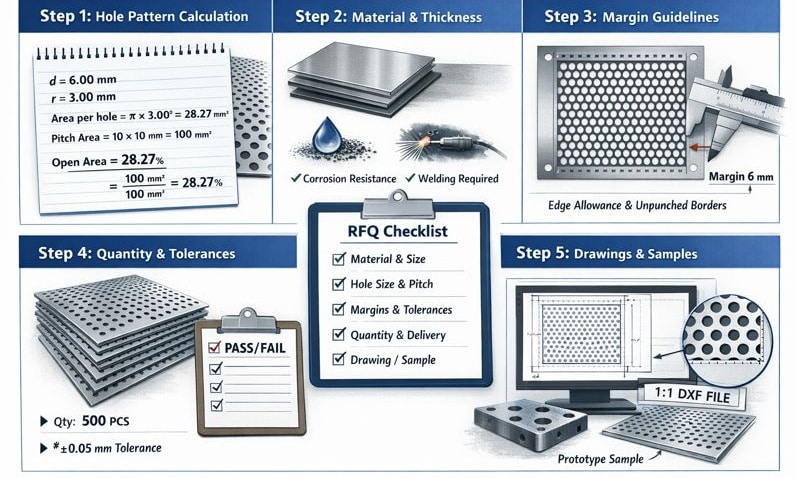

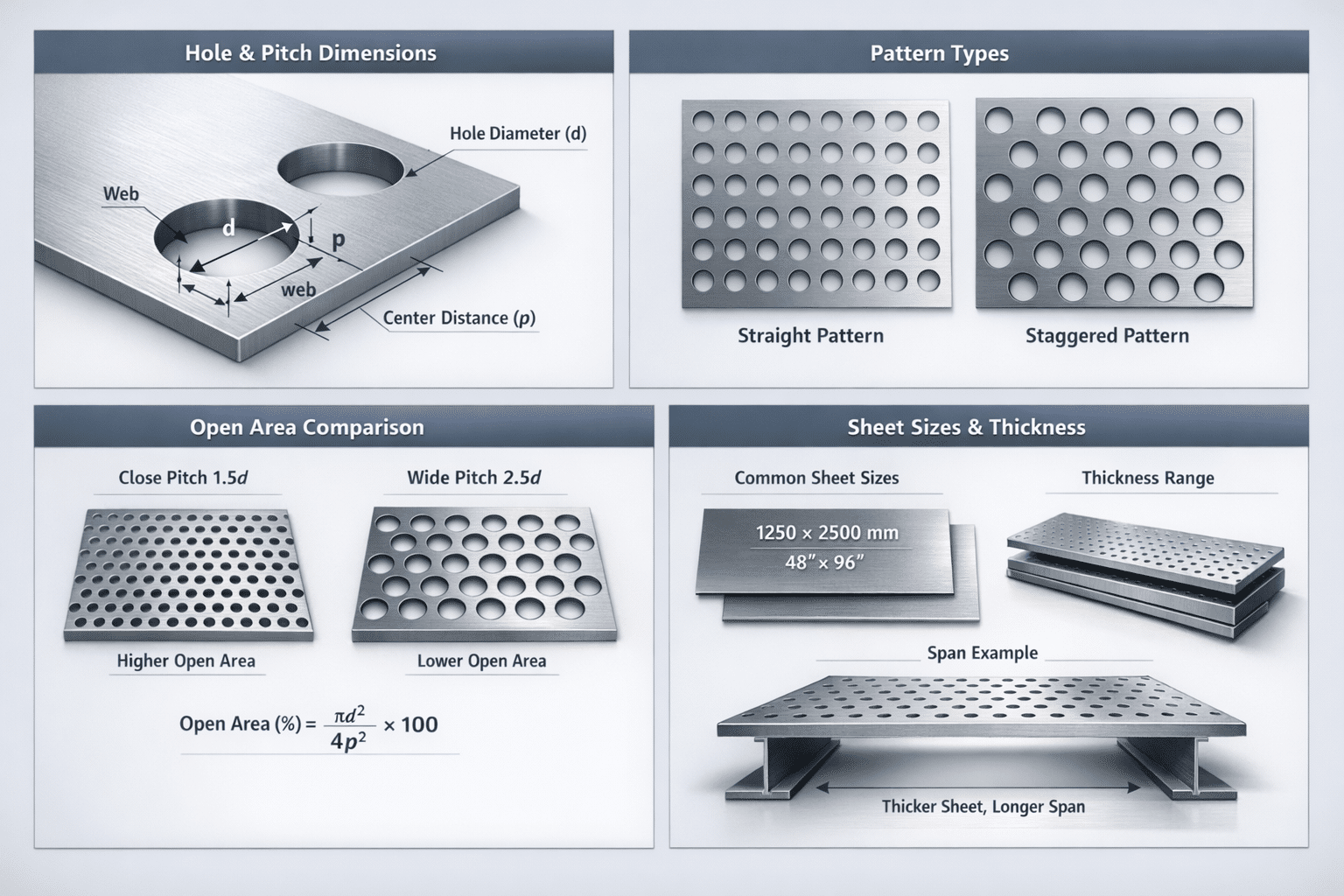

Engineering Considerations We Discuss Before Quoting

A good perforated sheet quote is not only “hole size and thickness.” For 5052 projects—especially marine or machinery guarding—we usually confirm:

Hole diameter, pitch, and open area

- Small holes + tight pitch improve screening but can reduce ligament width and stiffness

- Higher open area improves airflow but may require thicker sheet or reinforcing

Thickness and panel span

- Longer spans and higher vibration often need thicker material or framing

- Edge margins (unperforated borders) can greatly improve rigidity and fatigue life

Flatness, tolerances, and fabrication steps

Perforation can introduce slight movement in the sheet. If a project requires tighter flatness, we may recommend:

- Stress-aware perforating sequence

- Leveling considerations

- Cut-to-size after perforation

- Frame integration to maintain final assembly flatness

Finishing for marine and outdoor use

Depending on the environment, customers may choose:

- Anodizing for appearance and added surface protection

- Powder coating for strong barrier protection

- Brushed finishes for architectural projects

Manufacturing Reliability: How We Control Quality on 5052 Perforated Sheets

When your buyer is comparing suppliers, performance claims aren’t enough. Consistency is what matters.

For 5052 Aluminum Round Hole Perforated Screens, we focus on process control points that affect fit and function:

- Hole accuracy and pattern consistency across the full sheet

- Burr control and clean edges for safe handling

- Dimensional control after perforation

- Packaging that protects surface finish during transport

If a customer needs documentation for internal QA, we can support common expectations such as:

- Material verification (by request)

- Inspection records for critical dimensions

- Photo confirmation of finished lots prior to shipment

Where 5052 Aluminum Round Hole Perforated Screens Are Commonly Used

Customers often choose 5052 when the project demands durability more than “lowest cost.” Typical applications include:

- Marine ventilation grilles and protective screens

- Coastal building facades and soffit ventilation panels

- Heavy machinery guarding and safety enclosures

- Equipment intake/outlet screens (airflow + impact resistance)

- Transportation and industrial flooring support panels (when designed properly)

Closing: The Material Choice That Supports Long Service Life

If your project involves salt air, washdowns, constant vibration, or long-term outdoor exposure, 5052 is a smart foundation. Combined with the right thickness, hole layout, and finishing, it delivers the dependable performance buyers expect from Aluminum Round Hole Perforated Screens—not just at installation, but years later.