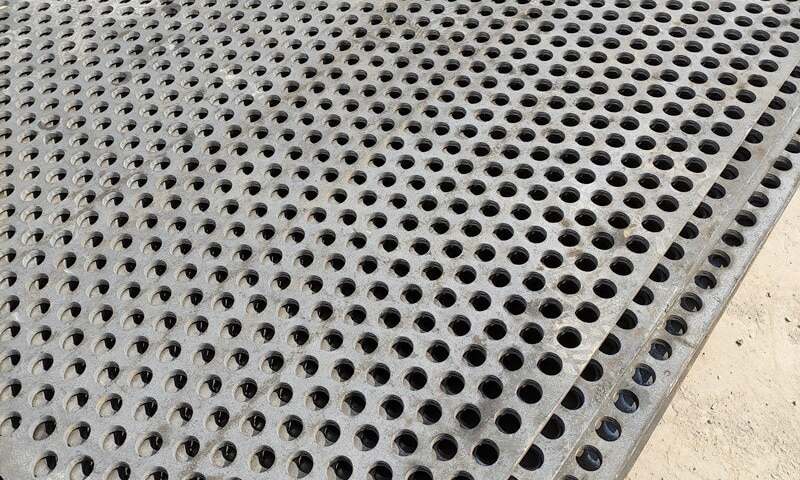

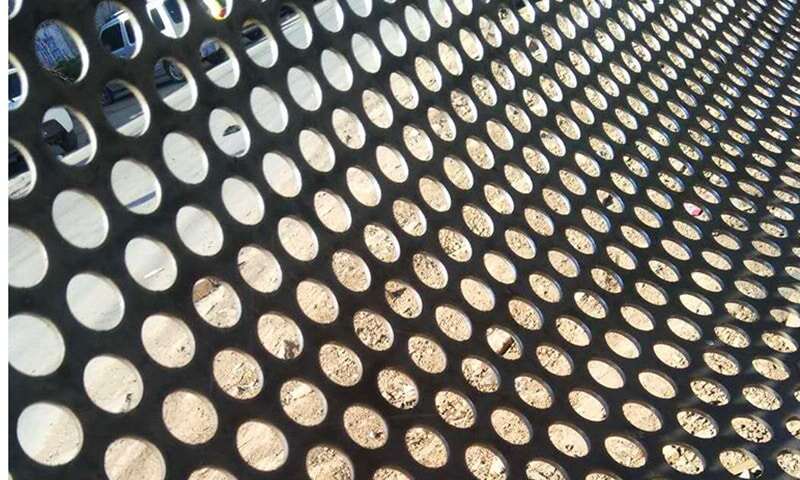

When a project requires strong abrasion resistance and excellent toughness, choosing the correct grade of high-manganese material matters. This article explains how common grade differences influence durability and manufacturability, and offers clear, practical tips for selecting a high-manganese perforated plate for screening, guarding, or protective panels.

Why high-manganese alloys are chosen

High-manganese alloys stand out because they harden during service when subjected to repeated impact or heavy abrasive contact. That in-service work hardening delivers longer life in applications such as mining screens, crusher guards, and heavy-duty filtration. For parts that combine impact and sliding wear, a properly chosen high-manganese perforated plate often outperforms simple carbon steel.

Key grade distinctions to watch

Manufacturers typically vary manganese and carbon levels and use different heat-treatment strategies. Some grades prioritize initial ductility to ease punching and forming; others are formulated for maximum work-hardening in service. When evaluating datasheets, review chemical composition, guaranteed toughness, and any recommended hardness ranges after forming. These parameters determine how the material will behave once perforated and put into service.

How grade affects perforation and forming

A harder grade increases punching forces and tooling wear. If you plan complex hole patterns—round holes, square holes, hex holes, slots—discuss them with your fabricator before full production. Different hole shapes and open-area ratios change local stresses and can alter the effective hardness after working; that in turn influences long-term wear performance.

Match grade to application

For heavy mining or crushing environments choose a grade with high work-hardening potential so the facing surface becomes tougher after initial wear. For architectural or decorative uses where formability and a consistent finish are important, choose a more ductile grade that still offers reasonable abrasion resistance. Consider whether the perforated panel is load-bearing or primarily decorative—this distinction changes thickness and grade recommendations.

Specification checklist (practical)

- State the dominant wear mode (impact vs. sliding abrasion) and any chemical exposure.

- Specify thickness, hole pattern (round / square / hex / slot), hole diameter, and open-area percentage.

- Include expected service life or target replacement interval to allow cost-optimized grade selection.

- Note manufacturing constraints such as maximum tolerable burr and minimum forming radius.

Coatings and finish

Surface treatments can protect against corrosion but may interact with work-hardening behavior. If a galvanised or polymer-coated finish is required, confirm coating compatibility with the chosen alloy and whether coating is applied before or after perforation.

Testing and acceptance

Ask for mill certificates, and when possible, a small trial run. Hardness mapping after perforation and forming helps predict wear rates. For long-term contracts consider specifying acceptance tests or a limited pilot delivery to validate performance.

Ordering and customization

Look for suppliers who support small minimum orders and scaled production, and who can supply different sheet sizes, thicknesses, and custom hole geometries. If your project benefits from alternate materials for comparison, request samples of other products such as stainless steel perforated plate or aluminum perforated plate for lightweight or corrosion-prone environments. For sheer abrasion resistance, ask for our High-manganese steel perforated plate product page and sample options. round and square-h to see typica

Final recommendation

Chinfo@perfsheet.com.