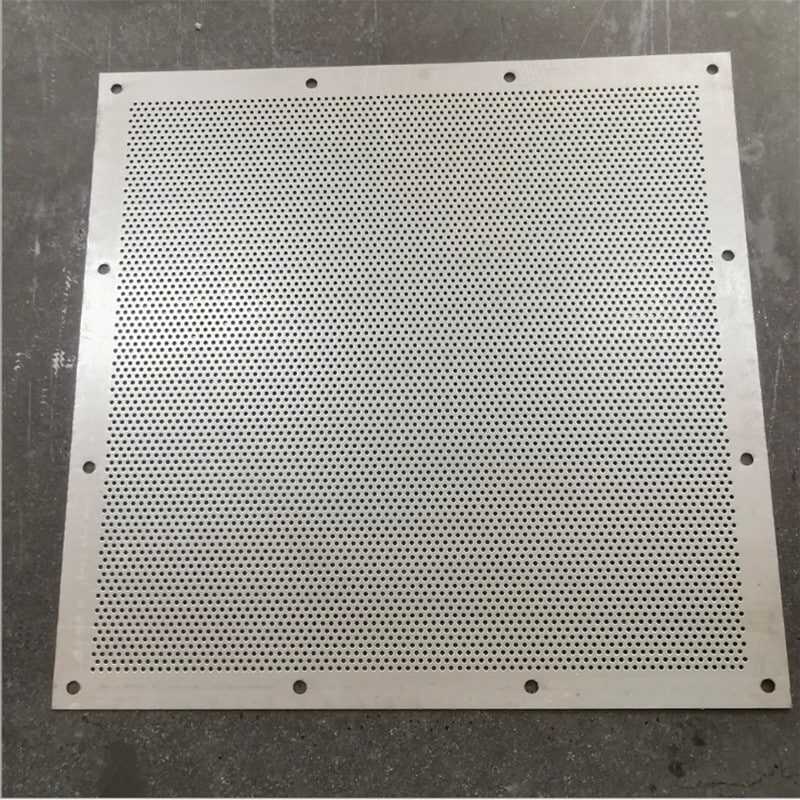

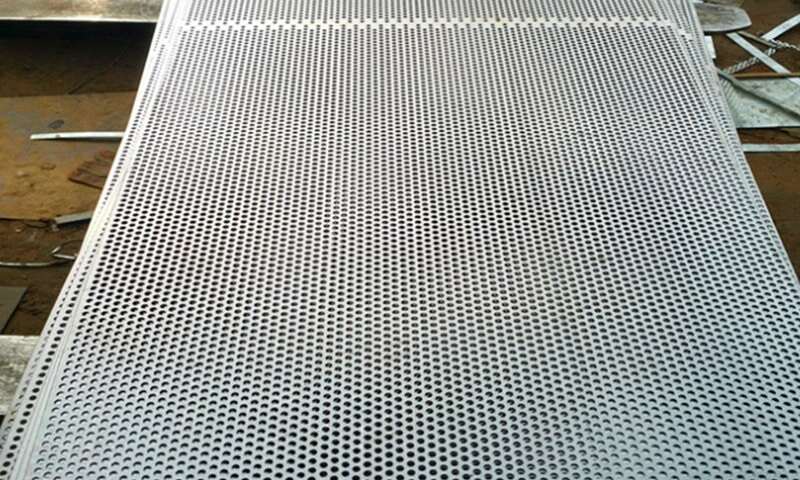

Micro perforated metal sheets play a key role in precision filtration applications where controlled airflow and particle capture are required. This article explains how the open area ratio relates to filtration efficiency, and which design choices—hole size, pattern, material, and thickness—help achieve the desired balance between throughput and retention.

What is Open Area Ratio?

The open area ratio (also called open area or open area percentage) describes the portion of a sheet’s total area that is occupied by holes. It is usually expressed as a percentage. Open area strongly affects airflow rates, pressure drop across a filter, and the sheet’s capacity to intercept particles.

- Higher open area → increased airflow, lower pressure drop, but typically reduced particle interception per pass.

- Lower open area → more resistance to flow, higher pressure drop, but better particle capture and structural rigidity.

Designing an effective micro perforated metal sheet requires choosing the open area that best matches the filtration target and system constraints.

How Open Area Affects Filtration Efficiency

Filtration efficiency depends on multiple interrelated variables; open area is one of the most critical:

- Airflow and Velocity

A larger open area provides higher volumetric flow at a given pressure differential, reducing flow velocity through each hole and potentially changing capture dynamics for particles of different sizes. - Particle Capture Mechanisms

Micro perforated sheets rely primarily on interception and inertial impaction at small scales. Smaller holes and reduced open area increase the likelihood that particles will contact the metal surface and be captured. - Pressure Drop

Increasing open area reduces pressure loss across the sheet, which may be essential in systems with limited fan or pump capacity. However, too large an open area can lower filtration efficiency below acceptable levels.

Typical practical ranges:

- High open area (>40%): favored where free flow and low pressure drop are priorities (e.g., architectural vents, pre-filters).

- Medium open area (20–40%): useful for balanced filtration where some particle retention is required with moderate flow.

- Low open area (<20%): chosen for fine filtration tasks where particle retention per pass is paramount.

Hole Size and Pattern: Small Changes, Big Effects

Micro perforated metal sheets typically have hole diameters in the sub-millimeter to 1 mm range. The hole shape and arrangement also change performance:

- Round holes offer symmetry and predictable flow behavior; they are common in many filtration designs.

- Staggered patterns can increase open area while preserving mechanical strength.

- Close-pitched small holes improve particle interception but raise manufacturing difficulty and cost.

For example, a sheet with 0.5 mm round holes at a tight pitch might achieve significantly higher capture for particles in the 1–10 µm range than a sheet with 1.0 mm holes, even if their open area percentages are similar. That’s because local velocity profiles and interception probabilities differ with hole geometry.

Material and Thickness Considerations

Material choice affects corrosion resistance, mechanical strength, and surface properties that influence long-term filtration performance.

- Stainless steel: excellent chemical resistance and strength; suitable for demanding industrial filtration and repeatedly cleaned filters.

- Aluminum: light and corrosion-resistant for non-aggressive environments where weight matters.

- Carbon steel (coated/galvanized): cost-effective option for less corrosive applications.

Sheet thickness interacts with hole size and open area to determine stiffness. Thicker sheets resist deformation and clogging under high flow conditions, while thinner sheets can be preferable where minimal weight and flexibility are needed.

Design Trade-offs and Typical Use Cases

When specifying a micro perforated metal sheet, engineers usually balance these goals:

- Maximize filtration efficiency: choose smaller holes, closer pitch, and lower open area; consider stainless steel for cleanability.

- Minimize pressure drop: increase open area and use larger holes; select materials that maintain shape under flow.

- Optimize for cleaning and maintenance: prefer patterns that allow backflushing or easy mechanical cleaning, and materials tolerant to the cleaning process.

Common applications include precision air filters, pre-filtration stages for HVAC or process equipment, acoustic absorbers that double as filters, and liquid filtration where controlled flow and particle retention are required.

Practical Tips for Specifying Micro Perforated Sheets

- Start with target particle size and allowable pressure drop. These two constraints narrow the feasible open area and hole size combinations.

- Prototype and measure. Small design changes can have outsized effects; bench testing under real flow conditions is essential.

- Consider cleaning cycles. If the sheet must be cleaned frequently, prefer stainless steel and designs that tolerate backwashing.

- Ask about customization options. Many suppliers can provide one-off samples to validate performance before committing to large orders.

Conclusion

Open area ratio is a central parameter in the performance of micro perforated metal sheets. By carefully selecting hole diameter, pattern, material, and thickness—and by validating designs with real-world testing—engineers can achieve the right balance between filtration efficiency and airflow. Thoughtful customization yields filtration media that meet specific operational demands without unnecessary compromise.