In industrial, architectural, and environmental engineering fields, round hole perforated metal sheets are among the most commonly used materials for managing airflow and filtration. They are valued for their clean design, strength, and versatility. But what truly determines their performance in ventilation systems is the open area—a critical factor directly influencing air circulation and pressure loss.

What Is Open Area in Perforated Metal?

The open area refers to the percentage of a sheet’s surface that consists of holes. It represents how much space is available for air, light, or sound to pass through. The open area is influenced by three main parameters:

- Hole diameter

- Center-to-center spacing (pitch)

- Hole arrangement pattern (staggered or straight)

A larger hole or closer spacing increases the open area, while smaller holes or wider spacing reduce it. The challenge lies in selecting the right configuration that maintains both airflow and material strength.

How Open Area Influences Ventilation Efficiency

Ventilation efficiency measures how effectively air can pass through a perforated surface. In general, a higher open area allows for smoother airflow and reduced air resistance. However, more holes also mean thinner supporting metal sections, which can lower the sheet’s rigidity and affect durability.

Balancing air permeability, strength, and acoustic behavior is therefore essential.

The appropriate open area depends primarily on the intended function rather than the product category:

- 10–25% open area — Suitable for protective or structural purposes, such as safety guards, screening panels, or enclosures that prioritize strength over airflow.

- 25–40% open area — Ideal for moderate ventilation or filtration, often used in air diffusers, partition panels, and machinery covers that need both airflow and support.

- 40–60% or higher open area — Best for cooling, sound absorption, and ventilation systems, where airflow volume and reduced pressure drop are more important than rigidity.

In professional practice, engineers define the open area according to airflow rate, noise control, and static pressure requirements rather than by material alone.

Why Round Hole Patterns Perform Best

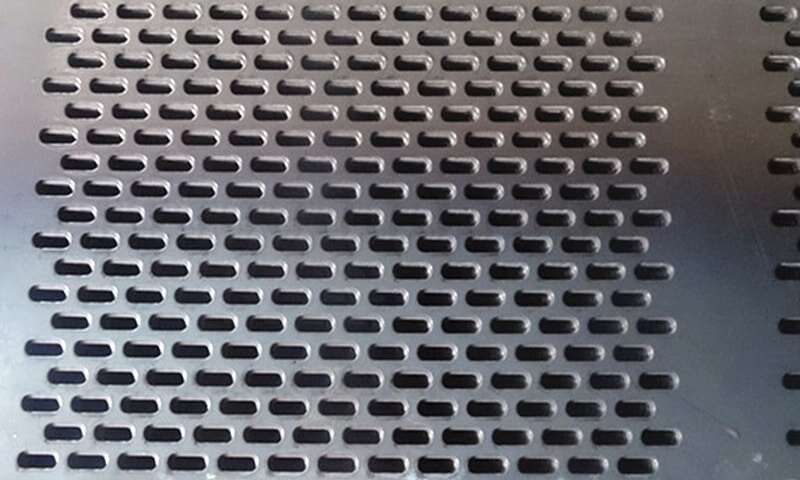

Among various perforation shapes—round, square, hexagonal, or slotted—the round hole perforated metal sheet provides the most balanced performance. The symmetrical hole geometry ensures even airflow distribution, minimizes turbulence, and maintains consistent mechanical strength.

Compared with hexagonal or slotted perforations, round holes offer slightly lower airflow at equal open area but deliver superior stress resistance and cleaner visual appearance. This is why round hole patterns are widely used in ventilation covers, architectural facades, and acoustic panels.

Selecting the Right Material and Thickness

The material and thickness of a perforated metal sheet also affect ventilation efficiency.

- Aluminum perforated metal sheets are lightweight, corrosion-resistant, and ideal for architectural facades or ceiling systems.

- Carbon steel perforated metal sheets offer high strength for structural or industrial ventilation.

- Stainless steel perforated metal sheets are preferred in environments requiring hygiene and durability, such as food processing or chemical plants.

- Galvanized perforated metal sheets balance cost and corrosion resistance for outdoor applications.

- Micro perforated metal sheets are often used where acoustic control and uniform airflow are needed.

Thinner sheets improve airflow but may deform under stress, while thicker sheets provide stability but increase resistance. The right balance depends on the airflow rate, load requirements, and environmental conditions.

Applications Where Ventilation Efficiency Matters

High ventilation efficiency is crucial in many industries and architectural applications. Some common uses include:

- HVAC systems and air diffusers

- Acoustic wall panels and ceilings

- Filtration units and separators

- Lighting and machine protection covers

- Decorative facades and sunshade panels

For instance, round hole aluminum perforated panels used on building facades not only promote natural ventilation but also help regulate light transmission, improving energy efficiency and indoor comfort.

Balancing Aesthetics, Function, and Airflow

Designing with perforated metal is always a process of balance. The open area influences not only ventilation efficiency but also the sheet’s appearance, sound performance, and strength.

By adjusting hole diameter, spacing, and material type, manufacturers can provide custom perforated metal solutions tailored to each project’s requirements.

Whether you need carbon steel, stainless steel, or aluminum perforated sheets, customization enables precise control over airflow performance and design aesthetics. Factories with advanced perforation equipment can produce sheets in various thicknesses, patterns, and surface finishes—even supporting one-off prototypes or large-scale production runs.

Conclusion

The relationship between open area percentage and ventilation efficiency is fundamental to achieving optimal performance in round hole perforated metal sheets. By understanding how open area affects airflow, strength, and sound properties, engineers and designers can make informed decisions that enhance both functionality and aesthetics.

Whether your goal is maximum ventilation, structural safety, or visual appeal, choosing the right open area and material combination ensures your perforated metal solution performs exactly as intended.

For professional customization or quotations, contact us at info@perfsheet.com.