Achieving reliable ventilation performance starts with understanding one critical feature of perforated metal panels: open area, also known as perforation ratio.

For cross-shaped perforated plates, open area plays an even more important role because the geometry of the cross hole influences airflow behavior differently than round or square perforations.

This article explores how open area affects ventilation efficiency, pressure drop, noise characteristics, and overall performance — and how to choose the right configuration for customized industrial or architectural applications.

What Is Open Area and Why It Matters

Open area is the percentage of the sheet surface removed by holes.

A higher open area generally means:

- Better airflow

- Lower pressure drop

- More light and sound transmission

However, for cross-shaped perforations, the orientation and arm angles of the cross hole generate unique airflow patterns that cannot be evaluated purely by percentage alone.

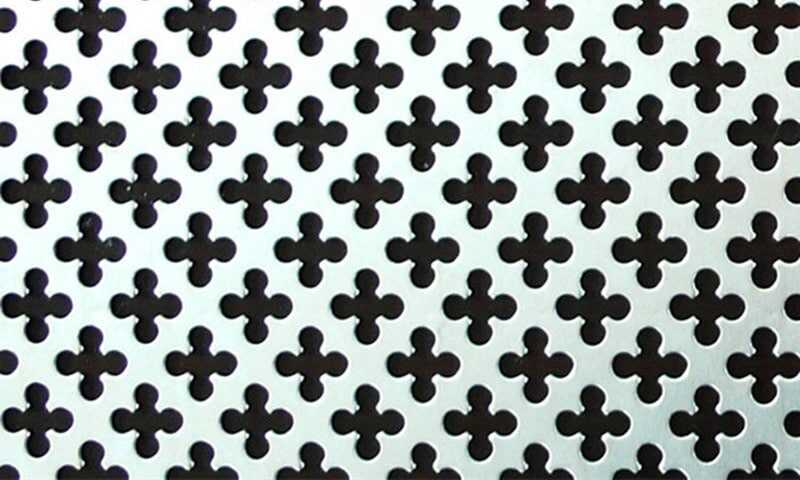

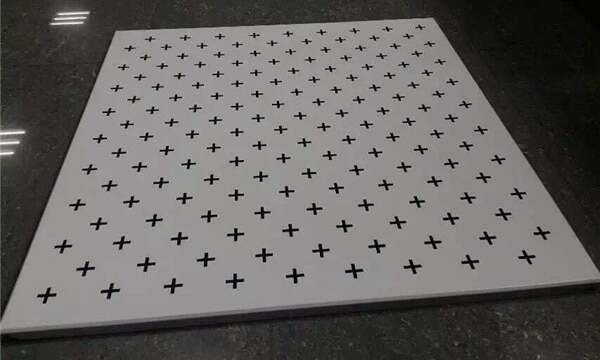

To explore a real example, take a look at a standard cross-shaped ventilation plate, which balances structural strength with relatively high free area.

How to Calculate Open Area (Simple Example)

Open Area Formula:

Open Area (%) = (Sum of All Hole Areas ÷ Total Sheet Area) × 100

For instance:

A 1000 × 1000 mm sheet = 1,000,000 mm² surface area

If the total hole area = 250,000 mm²

Then the open area = 25%

This becomes the base reference when estimating airflow capability.

How Open Area Influences Airflow and Pressure Drop

Airflow through perforated plates is controlled by open area, hole shape, and plate thickness.

Below is a general guideline:

Low Open Area (Below 10–15%)

- Higher resistance to airflow

- Higher pressure drop

- More suitable for decorative, protective, or low-ventilation applications

Medium Open Area (15–40%)

- Best balance of ventilation and rigidity

- Most HVAC and industrial uses

- Cross-shaped holes in this range often outperform square holes due to smoother airflow paths

High Open Area (Above 40%)

- Very low pressure drop

- Behaves close to a mesh

- May require thicker material or reinforcement to maintain stiffness

Important note:

Two panels with the same open area may behave differently if hole shapes or thicknesses differ. Cross-shaped openings can create less turbulence than sharply cut square holes.

Secondary Effects: Sound and Light Transmission

Open area affects more than airflow.

A higher perforation ratio can increase:

- Light transmission

- Sound passage

Cross-shaped holes, however, scatter sound more effectively due to their arm geometry.

This can be beneficial for:

- Machine enclosure ventilation

- Acoustic shielding

- Industrial noise reduction setups

Pairing a perforated plate with acoustic backing material can further improve noise control.

Choosing Materials and Thickness for Best Ventilation

Material choice influences strength, weight, corrosion resistance, and overall air performance.

Popular options include:

- Carbon steel perforated sheets — strong and economical

- Galvanized steel perforated sheets — ideal for outdoor or industrial corrosion resistance

- Stainless steel perforated plates — excellent for hygiene and long-term durability

- Aluminum perforated sheets — lightweight, ideal for architectural use

Thickness Tip:

Thicker sheets increase structural strength but lengthen the airflow path through each hole, slightly increasing resistance.

To compensate, designers often increase open area or choose wider cross arms.

Practical Design Tips for Optimizing Ventilation

- Define airflow needs first

Start with required CFM or L/s. Work backward to calculate the needed open area. - Request real samples

Airflow and noise behavior vary by shape — testing a small sample is often very helpful. - Use staggered hole patterns

Improves sheet strength without reducing open area. - Improve edge flow

Deburring or chamfering hole edges reduces turbulence and noise. - Combine with acoustic or filtration backing when needed

This is especially common in HVAC and industrial exhaust applications.

Where Cross-Shaped Perforated Plates Perform Best

These perforated plates provide an excellent mix of strength and ventilation in applications such as:

- HVAC supply and return grilles

- Noise-control and machine enclosures

- Architectural facades

- Equipment ventilation covers

- Industrial guards and protective screens

Their unique airflow behavior and customizable open area give them a performance edge in both functional and decorative roles.

How to Specify Your Order

To ensure accurate production and optimal performance, provide:

- Sheet dimensions (example: 1000 × 2000 mm)

- Material and thickness

- Cross-hole dimensions or drawings

- Required open area

- Airflow or pressure-drop targets

- Finish type (powder coat, anodizing, etc.)

- Quantity (supports single-piece and bulk orders)

This allows fast quoting and precise manufacturing.

Conclusion

The open area of cross-shaped perforated plates is the key factor influencing ventilation performance.

But equally important are the hole geometry, plate thickness, and spacing — all of which must work together to achieve the airflow, pressure, and acoustic performance your project requires.

If you need guidance, airflow calculations, or a custom prototype, feel free to reach out.

Contact / Request a Quote

📧 info@perfsheet.com