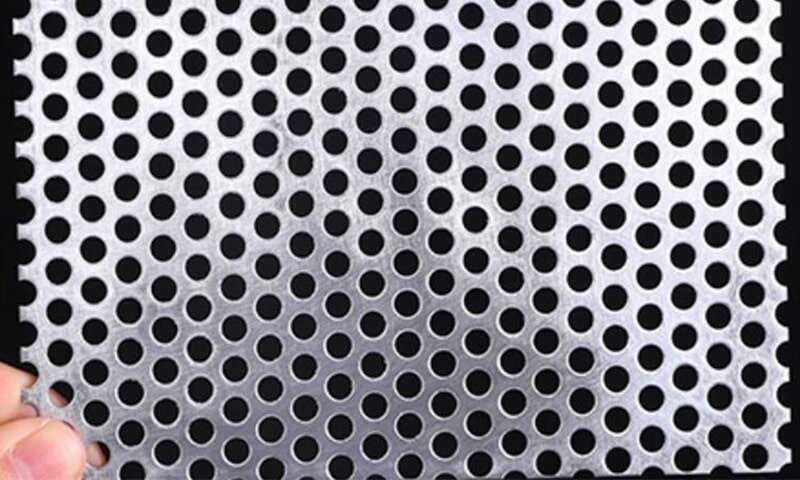

Coastal environments are demanding: constant salt spray, high humidity, and fluctuating temperatures accelerate corrosion and wear. For architects, fabricators, and procurement teams specifying metal panels, choosing a finishing method and material that can stand up to these conditions is critical. Hot-dip galvanized perforated metal sheet offers a practical, cost-effective solution that balances corrosion protection, structural performance, and aesthetic flexibility — especially when manufacturers can supply custom dimensions, thicknesses, hole patterns, and opening rates to suit specific projects.

Why coastal environments are different

Salt-laden air dramatically increases the electrochemical reactions that cause rust. What takes years to show inland can appear in months near the shore. In addition, coastal installations are often subject to windborne abrasion, occasional bird droppings, and UV exposure — all factors that combine to reduce the lifetime of exposed metal surfaces. That’s why material choice and protective coatings must be made with realistic service conditions in mind.

What hot-dip galvanizing brings to perforated metal

Hot-dip galvanizing deposits a thick, metallurgically bonded zinc layer onto the steel surface. For perforated sheets this is especially valuable because:

- Complete coverage over edges and holes. Unlike some thin coatings that can be uneven at cut edges, hot-dip galvanizing forms a continuous layer that wraps around perforations and cut edges, which are common corrosion initiation points.

- Cathodic protection. Even if the zinc layer is scratched, the zinc will preferentially corrode and protect the steel beneath, extending service life.

- Low maintenance. Galvanized surfaces typically need less frequent recoating or repair than painted or untreated steel in coastal settings.

- Cost-performance balance. Compared with high-end stainless grades, galvanized steel can offer excellent life-cycle value for many architectural and industrial uses.

When the project requires different mechanical properties or aesthetics, alternatives like stainless steel perforated metal sheet or aluminum perforated panels remain good options — but hot-dip galvanizing is often the sweet spot for performance vs. cost.

Material and pattern choices that matter

Perforated metal is not one-size-fits-all. For coastal projects consider:

- Base material: Carbon steel with hot-dip galvanizing is commonly used for grills, sunscreens, and façade infill. For very aggressive marine environments, higher-grade <a href=”/products/stainless-steel-perforated-sheet”>stainless steel perforated metal sheet</a> may be preferred.

- Thickness & span: Thicker gauges resist deformation and reduce vibration from wind. Work with your fabricator on recommended spans for the intended gauge.

- Hole type & open area: Round, square, hexagon, slot and micro-perforations all behave differently. Larger open area improves ventilation but reduces stiffness; smaller holes keep stiffness but can trap salts. Example product pages: round hole perforated metal sheet, square hole perforated metal sheet, slot perforated metal sheet.

- Edge treatment: Pay attention to edge trimming and post-perforation processing — burrs and unfinished edges corrode faster if not properly treated before galvanizing.

Also consider specialty options such as micro-perforated metal sheet for acoustic panels or perforated safety grating for walkways and platforms.

Installation and maintenance best practices

Even the best material needs correct detailing and routine checks to reach its expected lifespan. Useful, human-tested steps include:

- Secure fastening systems that avoid crevice corrosion (use stainless fasteners or compatible coatings).

- Design details that avoid water trapping — provide drainage paths behind panels.

- Periodic rinsing: a fresh-water rinse every 6–12 months reduces salt buildup on exposed surfaces.

- Prompt touch-up: if severe damage exposes base steel, apply appropriate repair zinc or paint to limit localized corrosion.

- Regular inspections after storms or seasonal heavy winds.

Testing, standards, and real-world performance

Look for galvanizing that meets recognized standards and consider accelerated testing (salt spray or cyclic corrosion tests) when comparing suppliers. A practical approach is to request comparative samples: galvanized, stainless, and aluminum perforated sheets, then evaluate appearance, adhesion, and edge protection after testing. This helps buyers match product specs to project budgets and expected exposure.

Typical applications in coastal settings

Hot-dip galvanized perforated panels are commonly used for:

- Building façades and sunshades

- Balustrades and screening

- Mechanical ventilation grilles

- Safety walkways and gratings

- Decorative cladding and signage

Their combination of airflow, light diffusion, and protection makes them versatile — especially where custom sizes, hole patterns, and opening rates are required.

Practical selection checklist (quick)

- Identify exposure level (splash zone vs. airborne salt).

- Choose base metal and gauge for structural needs.

- Select hole pattern/opening rate that balances airflow, appearance, and stiffness.

- Confirm hot-dip galvanizing specifications and edge coverage.

- Agree on inspection and maintenance schedule with installer.

For coastal projects, hot-dip galvanized perforated metal sheet delivers a strong, economical defense against corrosion while preserving the design flexibility that perforated products offer. When combined with sound detailing and sensible maintenance, galvanized perforated panels can serve reliably for many years in seaside environments.

If you’d like help selecting the right perforated panel for a coastal project — whether it’s galvanized perforated metal sheet, stainless perforated panels, or specialty options like micro-perforated sheet — reach out and we’ll respond promptly: info@perfsheet.com.