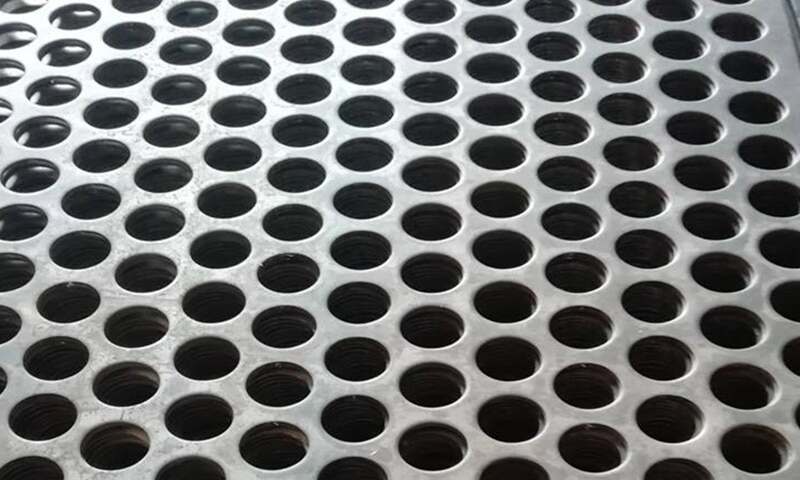

Perforated metal is a workhorse in industrial designs — from filtration and separation to safety guarding and ventilation. When corrosion resistance and long service life matter, choosing the right zinc coating becomes a key decision. This article explains, in clear industrial terms, how a hot-dip galvanized perforated plate differs from an electro-galvanized alternative, and which choice typically suits different industrial scenarios.

How the coatings are applied — process and structure

The two routes to zinc protection are fundamentally different. A hot-dip galvanized perforated plate is immersed in molten zinc; the zinc reacts metallurgically with the steel to form a multi-layered alloyed coating that bonds tightly to the base metal. Electro-galvanizing deposits a thin, mostly pure zinc layer onto the sheet via an electrochemical bath. The result: hot-dip coatings are usually thicker and mechanically robust, while electro-galvanized finishes are thinner with a smoother appearance.

Coating thickness, bonding and implications for perforated products

Because holes and edges create stress points, coating thickness and adhesion are vital. A hot-dip galvanized perforated plate typically has a heavier zinc weight (often specified in g/m² or oz/ft²) and the coating wraps over edges and inside holes more uniformly due to the dipping process. Electro plating can struggle in deep recesses or tight perforation geometries, so its effective thickness at hole edges may be lower — something to consider for highly punched or micro-perforated panels.

Corrosion resistance and expected lifetime

For demanding environments — chemical plants, outdoor machinery, coastal facilities, or ventilation systems where humidity and salt spray accelerate corrosion — the hot-dip galvanized perforated plate usually offers longer service life because of its thicker sacrificial layer and better edge coverage. Electro-galvanized sheets can be adequate indoors, in controlled environments, or where later topcoating (paint or powder coat) will be applied.

Mechanical durability and fabricating behavior

Industrial installations often require cutting, bending or welding after perforation. A hot-dip galvanized perforated plate provides a tougher barrier for wear and abrasion; however, if secondary fabrication is expected, the thicker coating may require touch-up at cut edges. Electro-galvanized perforated sheets permit finer surface finish and can be preferable where tight dimensional tolerances or precision painting follow.

Appearance, post-treatment and inspection

If the surface look matters under machinery or strict QA, electro-galvanized panels are smoother and more uniform visually. But for heavy-duty industrial parts such as machine guards, screens, ventilation guards, and perforated safety grating, the functional longevity of a hot-dip galvanized perforated plate often outweighs cosmetic considerations. Both substrates can accept passivation, chromate, or additional paint layers; choose treatments based on exposure and maintenance schedules.

Typical industrial use cases — which to choose

- Choose a hot-dip galvanized perforated plate for: outdoor safety grating, coastal HVAC cowls, heavy screening and sifting equipment, mining chutes, and any application exposed to salt spray, mechanical wear or infrequent maintenance windows.

- Consider electro-galvanized perforated plates for: indoor HVAC diffusers, control panel ventilation, light duty machine guards inside climate-controlled facilities, or when a smoother surface is prioritized before painting.

Specifying tips for procurement

- State required zinc weight (e.g., light, medium, heavy) or target corrosion life (years) when requesting quotes.

- Give punching details — hole type, diameter, open area (%) and edge requirements — so the supplier can advise on plating coverage.

- If welding or bending will follow, request recommendations for pre- or post-treatment and touch-up.

- For critical filtration, ask for flatness and burr tolerances.

Industrial examples and internal product references

If your project needs heavy-duty materials, our Perforated Safety Grating and galvanized perforated sheet product lines handle demanding loads and corrosive conditions. For lighter, corrosion-resistant alternatives, consider our stainless steel perforated plate or aluminum perforated plate offerings — each product has different tradeoffs in weight, corrosion resistance, and fabrication behavior.

Conclusion & recommendation

In short, if long service life and robust edge coverage are priorities for industrial applications, the hot-dip galvanized perforated plate is the safer standard choice. For controlled-environment or finish-critical cases, electro-galvanized perforated plates can be a competitive option. Always specify the intended use, maintenance cycle and perforation geometry when ordering so the supplier can match coating method and zinc weight to your needs.

Call to action

For custom sizes, thicknesses, materials and perforation patterns we can run one-off prototypes up to large production volumes. Email our export team at info@perfsheet.com with drawing files, desired finish (hot-dip or electro), and application details for a quotation.