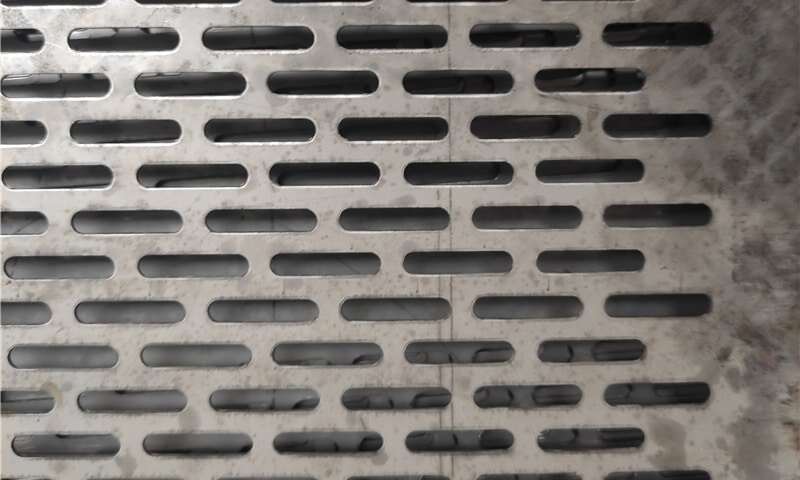

Perforated metal with slotted holes is widely used in façades, sunscreens, screening, acoustic panels, and industrial enclosures. Because slots present an anisotropic opening (long in one direction, narrow in the other), their geometry—slot width, length, orientation, spacing, and open area—has a direct and sometimes surprising effect on how wind flows around and through the panel. In this article I summarize practical findings and design guidance you can use when specifying or ordering a slotted perforated metal sheet for windy locations. The goal is to balance ventilation, visibility, structural needs, and wind-load performance so that the final part works exactly as intended.

Why slot geometry matters to wind resistance

Wind interacting with a perforated panel does three main things: it (1) passes through open area (reducing pressure on the downstream face), (2) accelerates and becomes turbulent within and just beyond openings, and (3) applies pressure and drag to the solid webbing between holes. Compared with round or square perforations, slots concentrate flow in one direction and change the way wake and vortex shedding form downstream. That affects:

- Pressure drop across the panel (important for ventilated enclosures).

- Static and dynamic wind loads on the supporting structure.

- Noise and aeroacoustic behavior when flow becomes turbulent.

- Visual permeability and solar shading performance (function + form).

A thoughtful slot design reduces unwanted pressure differentials and structural loading while keeping the ventilation and aesthetic properties you want.

Key geometric variables and their effects

Slot width (w)

Narrower slots (small w) restrict flow more per opening and increase local velocity through the aperture, which raises pressure loss per unit open area. Wider slots lower velocity and pressure loss but may compromise screening/appearance.

Slot length (l) and aspect ratio (l/w)

Longer slots create an elongated opening that behaves differently in crosswind than short or square holes. A high aspect ratio (long, thin slot) tends to channel flow and can produce strong directional permeability—good when you want ventilation in one direction but also more prone to directional vortex formation. Low aspect ratio slots (shorter) behave more like oblong holes and tend to distribute flow more evenly.

Orientation

Orientation relative to prevailing wind is critical. Slots aligned parallel to predominant wind reduce the effective blockage and tend to allow smoother passage. Slots perpendicular to wind act more like a series of short fins and produce higher drag.

Pitch and stagger (center-to-center spacing)

Closer spacing reduces the solid web width between holes, lowering structural stiffness but increasing overall open area (if slot size is constant). Staggered layouts can break up coherent vortex structures and reduce some aeroacoustic effects.

Open area / porosity

Open area (percentage of panel removed) is the single most important bulk property for wind transmission. For the same open area, many combinations of slot width/length/pitch are possible—each combination gives different aerodynamic and visual effects. Generally, a higher open area decreases overall wind load on the panel (because more air passes through rather than around), but very high open area may sacrifice strength or privacy.

Edge finish & thickness

Rounded slot edges or deburred slots reduce small-scale turbulence and can slightly reduce aerodynamic noise. Plate thickness combined with slot length defines the hydraulic/perforation aspect (like a short duct) — thicker plates with long slots can create a “tunnel” effect, which changes pressure drop.

Material & thickness: practical considerations

Material choice itself (carbon steel, galvanized, high-manganese steel, aluminum, stainless steel) has minimal direct effect on aerodynamic behavior — the geometry dominates. The material matters for strength, durability, corrosion resistance, and manufacturability:

- Aluminum is lighter and easier to mount where weight matters (see aluminum perforated sheet).

- Stainless steel is preferred for corrosive environments and higher structural performance (see stainless steel perforated panel).

- Galvanized or coated steel offers cost-effective corrosion protection for outdoor use (see galvanized perforated metal sheet).

Thickness affects stiffness and how the panel resists wind-induced deflection; for the same open area, thicker material increases weight and can change the effective “length” of a slot (affecting flow). When specifying slot perforations for high-wind areas, choose a thickness and carrier frame that meet local wind-load codes.

Practical design guidance (quick checklist)

- Define the primary need first: ventilation, visual screening, acoustic attenuation, or structural barrier. That will determine acceptable open area and slot dimensions.

- Target an appropriate open area: for general façade ventilation, 20–40% open area often balances airflow and solidity. For heavy ventilation, push higher; for privacy/shading, lower.

- Match slot orientation to prevailing wind: align slots parallel to the most common wind direction when possible.

- Avoid extreme aspect ratios without testing: very long, very narrow slots produce directional wakes—use them only when the application benefits from directional permeability.

- Use staggered patterns to reduce coherent vortex shedding when noise or vibration is an issue.

- Consider thickness and edge treatment: rounded edges or deburring reduce small-scale turbulence and finish-related flow noise.

- Prototype critical panels: a single full-scale panel or sample installed and tested on-site often reveals issues that calculations miss. For panels where performance is critical, combine engineering with a small production run.

Applications & real-world notes

- Sunscreens and architectural façades: slots oriented horizontally can provide shading and visual privacy while allowing airflow, but they must be sized so that wind loads don’t overload the support mullions.

- Industrial enclosures and machinery guards: prioritize open area for ventilation but protect openings with narrower slot widths to prevent ingress of large debris.

- Acoustic panels: microperforations or denser slot patterns combined with backing materials reduce tonal noise from machinery; slot geometry modifies both airflow and acoustic absorption. See also the microperforated metal sheet product.

- Filtration and screening: slot width is often determined by the particle size to be excluded; choose a slot pattern that meets functional separation while controlling flow resistance.

Also consider complementary perforation types—sometimes a mixed pattern (slots + round holes) provides the best compromise of appearance and performance. If your use-case is outdoors and exposed, a galvanized perforated sheet or stainless option is recommended for durability.

How to specify to your perforated-metal supplier (what to include in the RFQ)

When you request a quote, include the following to get accurate comparisons:

- Required slot dimensions (width × length) and orientation.

- Open area target (percentage) or acceptable range.

- Plate material and thickness.

- Panel size and whether seams or framing are required.

- Expected wind exposure (site description or local design wind pressure) and whether field testing or certification is required.

- Quantity and desired lead time—this manufacturer supports one-piece orders up to large batches.

- Any special finishing (galvanize, powder coat, anodize, edge rounding).

Conclusion

Slot geometry clearly affects wind resistance and the overall performance of the perforated panel. By thinking about slot width, length, orientation, open area, and material up front—and by using CFD, prototypes, or field trials where needed—you’ll reduce risk and get a panel that performs reliably in real wind conditions. Small design choices (orientation, stagger, edge finishing) often yield big improvements in behavior and occupant comfort.

Call to action

If you’d like a specification checklist, a quote, or help evaluating slot geometry for a particular project, email: info@perfsheet.com. Include the desired panel size, material, slot dimensions (or a target open area), and the intended application (façade, enclosure, acoustic panel, etc.), and we’ll respond with practical recommendations and a production quote.