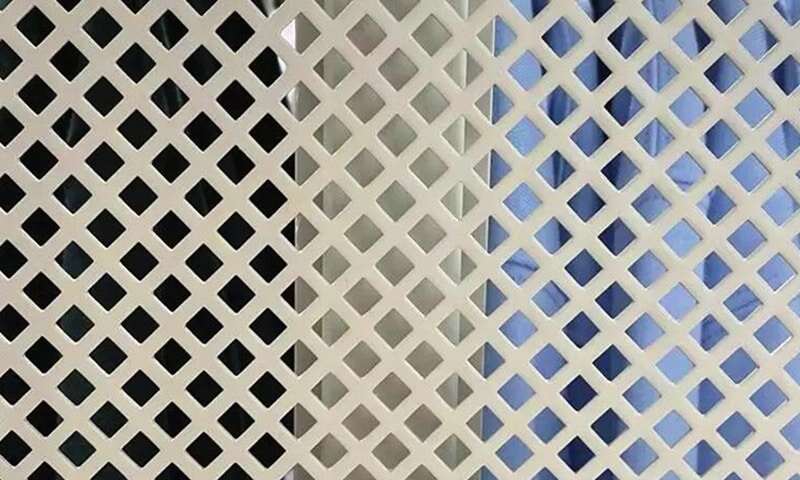

A square-hole perforated metal sheet often combines structural function with aesthetics. When a buyer or engineer asks whether to choose carbon steel, galvanized steel, high-manganese steel, aluminum, or stainless steel for a particular application, the answer depends on mechanical requirements: tensile strength, stiffness, fatigue life, impact resistance and long-term corrosion performance. This article explains how the same geometry — a square-hole perforated metal sheet — performs across common materials and offers practical selection guidance.

How geometry and material interact

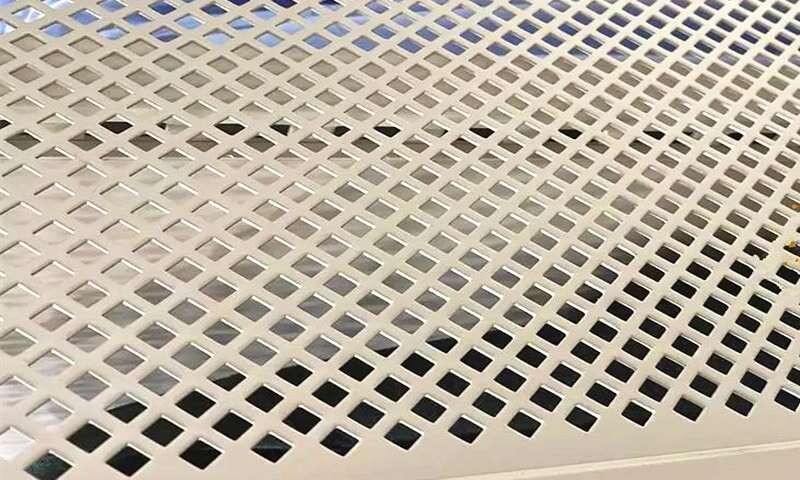

The mechanical behavior of a perforated plate is not just a function of base material. Hole size, open area (perforation ratio), sheet thickness and the edge condition around each square hole all change load paths and stress concentrations. A thicker square-hole perforated metal sheet will naturally have higher bending stiffness but also higher weight. Meanwhile, the same open area in aluminum and steel produces different stiffness-to-weight ratios.

Material-by-material comparison

Carbon steel

Carbon steel sheets are economical and provide good general strength. For moderate loads, a carbon square-hole perforated metal sheet gives predictable elastic behavior and good formability during punching. However, unless coated, carbon steel needs protection to avoid rust in humid environments.

Galvanized steel

Galvanized versions combine the mechanical traits of carbon steel with a corrosion-resistant zinc coating. Galvanizing can slightly affect fatigue life near the hole edges if the coating process changes edge microstructure, but for most architectural and industrial uses a galvanized square-hole perforated metal sheet balances cost and durability.

High-manganese steel

High-manganese steels (work-hardening types) excel where impact resistance and wear tolerance are needed. A square-hole perforated metal sheet made from high-manganese steel will usually show superior energy absorption and longer life under repeated impact. Consider post-processing (stress relief, edge finishing) to reduce residual punching stresses.

Aluminum

Aluminum reduces weight while keeping decent strength, especially with proper alloy choice (e.g., 5xxx or 6xxx series). An aluminum square-hole perforated metal sheet provides excellent corrosion resistance without coating and is preferred in transport, marine, and lightweight architectural panels. Aluminum has lower fatigue strength than steels at the same thickness, so design margins should reflect that.

Stainless steel

Stainless steels (304/316 and higher) combine corrosion resistance with good mechanical properties. A stainless square-hole perforated metal sheet is ideal when chemical resistance, hygiene or longer service life are required. Note: some stainless grades are less formable — punching parameters must be adjusted to avoid burrs that weaken edges.

Practical mechanics: what to test and why

When assessing a square-hole perforated metal sheet for a project, typical tests and checks include:

- Static tensile and yield measurements on representative panels (to confirm base material properties after punching).

- Bending stiffness tests for panels used as walkways or cladding.

- Fatigue tests if the panel will see cyclic loading or vibration.

- Visual and dimensional inspection of hole edge quality to assess stress raisers.

Design implications and selection tips

- For heavy structural loads choose thicker carbon or stainless sheets; for corrosive environments choose stainless or galvanized finishes.

- For weight-sensitive applications (vehicles, signage), favor aluminum with a well-designed thickness and higher perforation support spacing.

- Where impact or abrasive wear occurs, high-manganese grades prolong life.

- Minimize sharp corners at the square hole intersection — slight radii reduce stress concentration in all materials.

- Coordinate punching method and tooling with material: laser cutting changes edge microstructure differently than mechanical punching.

Short checklist for buyers

- Define load type (static / dynamic / impact).

- Specify environment (corrosion, temperature).

- Provide preferred hole geometry — here, square-hole perforated metal sheet — and desired open area.

- Ask the supplier for edge finish photos and representative test reports.

Conclusion

Choosing the right material for a square-hole perforated metal sheet depends on the balance between strength, weight, corrosion resistance and cost. By understanding how each material behaves after perforation — and by testing representative panels — buyers can select the best option for architectural, industrial or safety applications.