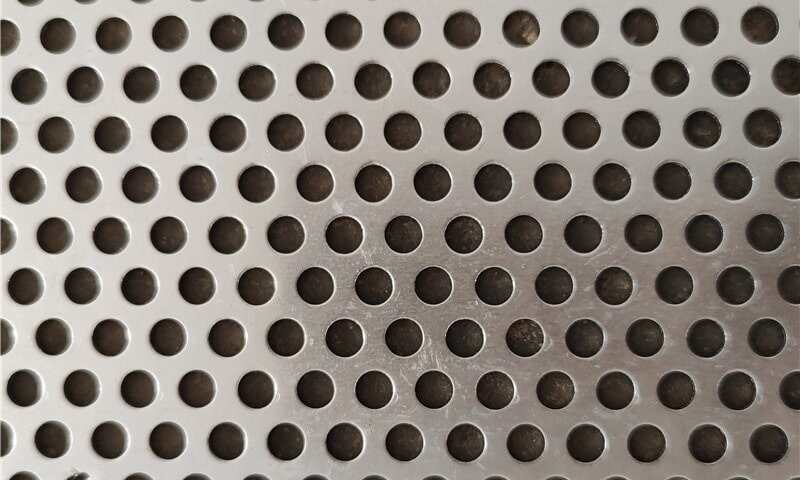

Selecting the right stainless steel grade is one of the most important decisions when sourcing perforated metal panels. Even when two sheets have the same hole pattern or thickness, their real-world durability can vary dramatically depending on the alloy behind them. From marine environments to architectural façades, corrosion resistance plays a crucial role in long-term performance, maintenance cost, and overall safety.

To help buyers make informed decisions, this article compares the corrosion behavior of several commonly used stainless steel grades—304/304L, 316/316L, 430, 201, and duplex 2205—and explains how each grade performs when manufactured into perforated stainless steel sheets.

Understanding Why Grade Matters in Perforated Sheet Applications

Perforated metal is unique because the large open area increases the exposed surface, which makes the alloy’s corrosion resistance even more critical. Each punched hole creates fresh edges, and these areas tend to corrode first in aggressive environments.

If the wrong grade is selected, even a well-engineered pattern—whether a round-hole perforated panel (e.g., stainless round perforated metal) or a slot-hole configuration (e.g., stainless slotted perforated sheet)—may fail earlier than expected.

Comparing Corrosion Resistance Across Popular Stainless Steel Grades

304 / 304L Stainless Steel

304 is the most widely used stainless steel for perforated sheets. It offers a balanced combination of affordability, strength, and corrosion resistance. In environments with moderate humidity, food-processing atmospheres, architectural screens, and machinery guards, 304 performs reliably.

The low-carbon version, 304L, provides improved weldability and helps prevent sensitization at the punched edges—useful when sheets undergo secondary fabrication.

Best Applications: interior decorative panels, ventilation screens, light-duty filtration, machinery protective covers.

316 / 316L Stainless Steel

For environments involving saltwater exposure, industrial chemicals, or chloride-rich settings, 316 is often the superior choice. Its higher molybdenum content significantly boosts resistance to pitting and crevice corrosion—two issues that frequently start around perforation edges.

316L, the low-carbon variant, remains stable during welding or high-temperature processing, making it ideal for projects that demand both high precision and long-term durability.

Best Applications: coastal building façades, marine equipment, chemical processing, outdoor enclosures.

430 Stainless Steel

430 offers basic corrosion resistance at a much lower price point. It is a ferritic stainless steel, meaning it lacks the nickel content found in 304 and 316. While still suitable for indoor and low-moisture environments, 430 is not recommended for coastal or chemical exposure unless the application is strictly temporary.

Buyers often select 430 to reduce cost when the perforated component is not subject to harsh conditions.

Best Applications: appliance panels, interior partitions, dry industrial environments.

201 Stainless Steel

201 is another economical option, using manganese and nitrogen to replace much of the nickel. While stronger than 304 in tensile strength, it offers noticeably lower corrosion resistance—particularly in environments with chlorides, humidity cycles, or acidic contaminants.

For decorative or lightweight structures where cost is a primary concern, 201 can be suitable, especially when used indoors or coated for extra protection.

Best Applications: decorative perforated panels, interior signage, displays, low-exposure architectural elements.

Duplex 2205 Stainless Steel

When conditions become extremely aggressive—such as offshore platforms, desalination plants, or highly corrosive industrial sites—2205 duplex stainless steel provides exceptional resistance. Its high chromium, molybdenum, and nitrogen content give it a much higher PREN value than conventional grades, allowing it to withstand environments that would rapidly pit 304 or even 316.

For perforated applications where structural load and corrosion resistance both matter, duplex 2205 offers one of the strongest combinations available.

Best Applications: offshore filtration systems, structural screening, high-pressure ventilation components.

How to Choose the Right Grade for Your Perforated Sheet Project

1. Evaluate the Corrosive Environment

- Light humidity → 304 / 430

- High chloride or chemical exposure → 316 / 2205

- Indoor decorative use → 201 / 304

2. Consider the Open Area & Hole Pattern

Higher open area increases exposure. For fine patterns like micro-hole perforated stainless sheets (e.g., stainless micro perforated panel), select a grade with a stronger corrosion threshold, especially if contaminants can settle into the pores.

3. Account for Fabrication Methods

If additional bending, welding, or shaping is required, 304L and 316L reduce the risk of corrosion at the heat-affected zones.

4. Balance Cost and Service Life

Cheaper grades may reduce the purchase price but can lead to higher replacement costs if used in unsuitable environments.

Conclusion: The Right Grade Ensures Long-Term Performance

The corrosion resistance of a perforated stainless steel sheet is determined primarily by its grade. Whether the project calls for a cost-effective option like 430 or 201, a versatile and reliable material like 304, or high-performance alloys such as 316 and duplex 2205, proper grade selection safeguards long-term stability, aesthetics, and safety.

If you need help choosing the right material or want a customized perforated sheet—whether round-hole, square-hole, slot-hole, hexagonal patterns, or other specialized designs—you can reach out anytime.

For inquiries, quotes, or customization details, contact:

info@perfsheet.com