Practical manufacturing rule: hole ≥ thickness

For heavy-gauge perforated work, a widely used rule of thumb is that the hole diameter should not be smaller than the plate thickness. This guideline exists because punching a hole that is smaller than the plate thickness concentrates shear and bending inside the punch/die pair, which increases burrs, tool wear, and the chance of punch breakage. Industry technical references and perforating suppliers state the same 1:1 minimum relationship as a baseline for carbon steels and aluminum; higher-strength alloys usually demand larger hole-to-thickness ratios or alternative processes.

Why the “hole ≥ thickness” rule matters

- Tool loading and life: Smaller holes raise shear stresses in the punch and die, shortening tool life and increasing maintenance downtime.

- Burr and edge quality: When the hole is close to or below thickness, the slug separation zone produces taller burrs and a poorer shear line.

- Part integrity: Small holes in thick plate can cause localized distortion or work hardening around the hole, affecting downstream assembly or fit.

Limits at both ends: what happens if holes are too small or too large

If the hole is too small (close to or below thickness)

- Excessive punching force and higher tonnage per hole — translates to increased production cost.

- Rapid punch/die wear, galling and higher burr heights — often forcing premature tool replacement.

- Higher scrap rates from torn edges or stuck slugs.

If the hole is very large relative to thickness

- Reduced remaining web (bridge) width between holes, which lowers structural stiffness and can cause local yielding under load.

- Edge tearing or elongation during forming or service if the bridge width is under-designed.

- For very large apertures (approaching the sheet width or large open areas), alternative processes (laser, plasma, waterjet, or CNC punching with secondary reinforcing) may be more appropriate.

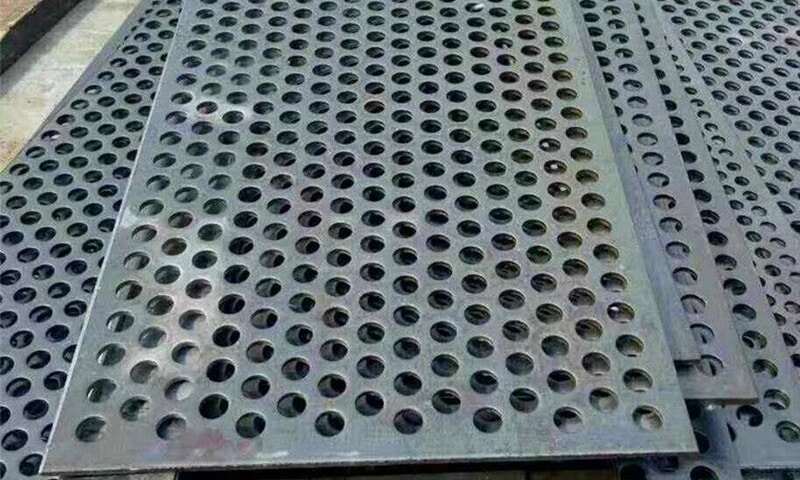

Heavy Duty Perforated Plates

Need a thick perforated plate made to drawing? Our program supports 2.75–30mm thickness, up to 6000×1500mm, with round/square/hex/slotted patterns, plus cut-to-size and surface protection for industrial installations.

Practical design rules and recommended checks

Use these engineering checks during specification and when reviewing shop feasibility:

- Start from the 1:1 baseline — require hole diameter ≥ plate thickness as the default for punching in most carbon and low-alloy steels. For stainless and high-strength alloys consider increasing the hole diameter or use laser cutting.

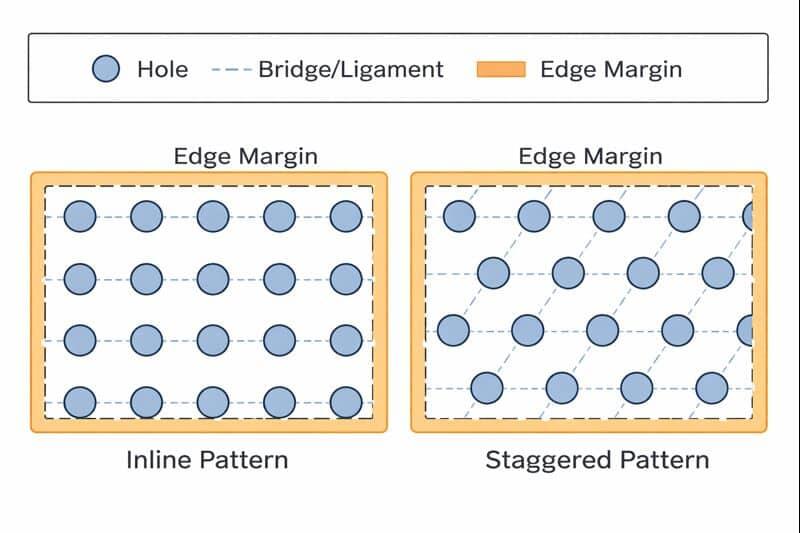

- Check minimum bridge (web) width — the smallest unperforated distance between holes (sometimes called c or bar) should be sized for the mechanical load and rigidity required. A common practical minimum is on the order of the material thickness; tighter bridges are possible but increase distortion risk.

- Punch/die clearance — specify total clearance as a percentage of material thickness; common practical ranges used in industry are roughly 10–20% total (i.e., 5–10% per side as a conservative starting point for many steels). Correct clearance reduces burr height and extends tool life, but excessive clearance risks slug pull. Always confirm with your toolmaker or die supplier.

- Pitch and pattern — tight pitch increases cumulative tonnage and the risk of plate distortion. For dense patterns consider staggered layouts (e.g., 60° stagger) to preserve stiffness and distribute stress.

- Material and thickness combination — verify feasibility with the fabricator. For example, a 2.75–30 mm thickness range and 3–300 mm hole range is technically possible across methods, but the cost and method (punch vs laser vs waterjet) will vary with exact combinations. Use shop trials for edge cases. (Use the product page specs as the manufacturing reference during procurement.)

Practical examples and quick rules of thumb

- If thickness = 10 mm, prefer hole diameter ≥ 10 mm for punching; ensure bridge width ≥ 10 mm for load-bearing panels or consider louvers/stiffeners if you must reduce bridge width.

- For very small apertures (3–6 mm) in thicker plates (≥6 mm): consider laser/EDM or re-evaluate pattern density — punching may be impractical or uneconomical.

- For holes > 50–100 mm in thin plates: check vibration and service loads — larger holes remove stiffness; add local reinforcement if needed.

Manufacturing & procurement checklist (for engineers / buyers)

- Confirm material grade (Q345, mild steel, stainless, high manganese, etc.) and verify any special allowances for stainless or high-strength steels.

- Provide thickness, hole diameter, pitch, bridge width, and required flatness after punching (leveling/flattening if needed).

- Ask the supplier for die clearance, estimated tonnage per hole, and tool life implications for the quoted pattern.

- For critical parts request a sample or small prototype run to validate edge quality and flatness before full production.

When to link this spec to a product decision

If you are sizing a load-bearing or protective panel, or you need an economical mass production run, consult your supplier about punching feasibility and tool life. For example, when specifying a heavy duty perforated plate or choosing a thick perforated plate for a platform or screen, include the hole/thickness/bridge values above so quotes and lead times are accurate.