Choosing the right perforated aluminum panel isn’t just about appearance — the panel’s open area (sometimes called the percent open) largely determines how much light passes through, how air moves, and how the panel performs in real-world applications. Whether you’re specifying panels for a sunshade, HVAC grille, façade, or interior divider, understanding open area helps you balance privacy, daylighting, ventilation, and structural needs.

What is open area and why it matters

Open area is the ratio of hole area to the total panel area, expressed as a percentage. A higher open area means more void space for light and air, while a lower open area gives greater visual screening and higher structural stiffness. Open area works hand-in-hand with hole shape, hole size, and material thickness to create the performance you need.

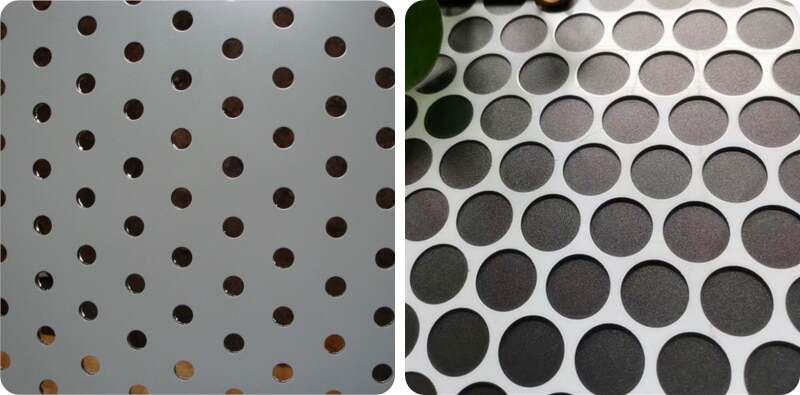

Quick example: two panels with the same open area can behave differently if one uses large round holes and the other uses many small perforations — the look, daylight quality, and airflow pattern will differ.

How open area affects light transmission

Light transmission through perforated aluminum is influenced by three main factors: the percentage open area, hole geometry (round, square, slot, etc.), and the thickness or depth of the metal. Practical takeaways:

- Higher open area → more daylight. If your goal is daylight harvesting (bring in natural light while reducing glare), panels with 30–60% open area are commonly used, depending on hole size and spacing.

- Hole size and daylight quality. Large holes transmit brighter, more directional shafts of light. Micro-perforations provide softer, diffused daylight that can reduce sharp shadows — useful for interior partitions or acoustic panels.

- Panel depth and light scatter. Thicker panels or panels installed some distance from glass will soften incoming light; thin panels flush against glazing transmit more direct light.

How open area affects ventilation and airflow

Airflow through perforated panels depends on open area, pressure differential, and hole arrangement. For ventilation:

- Open area is the primary driver: higher open area reduces flow resistance and increases free area for air exchange.

- Hole shape and orientation matter: slots oriented parallel to flow can deliver higher flow rates than staggered round holes for the same open area.

- Practical ranges: for light ventilation and decorative screens, 10–30% open area is common; HVAC grilles and functional louvers often require 40%+ open area or engineered slot patterns for effective flow.

If your application requires rated airflow (for example, an intake grille), it’s best to pair perforation specs with flow testing or engineering calculations to ensure the panel meets the needed CFM and pressure-drop limits.

Balancing light and ventilation — a few real-world guidelines

When you need both daylight and ventilation, follow these simple rules of thumb:

- Decide which is primary. If ventilation is critical (e.g., machinery enclosure), design for the required free area first, then adjust hole pattern for visual needs. If daylight is primary, select open area and hole size to achieve the desired luminance.

- Use mixed patterns where helpful. Many projects use a combination of patterns — larger perforations in low-visibility zones for airflow and smaller or micro-perforations where privacy or aesthetics matter.

- Consider stacking or layered panels. Two different perforated panels offset by a small gap can increase privacy while preserving airflow and diffuse daylight.

Applications and material choices

Different applications call for different materials and hole patterns. Common options:

- Aluminum Perforated Sheets — lightweight, corrosion-resistant, ideal for façades, sunshades, and interior features.

- Stainless Steel Perforated Sheets — used where strength and corrosion resistance under harsh conditions are required.

- Galvanized Perforated Metal — cost-effective for outdoor screening and industrial uses.

- Perforated Safety Grating — engineered for slip resistance and load-bearing walkways.

- Micro-Perforated Panels — excellent for acoustic treatment and soft, diffused daylight.

Pick the material based on environment (corrosive vs. benign), required finish, and weight constraints. Aluminum is often the default for architectural projects because it balances weight, corrosion resistance, and ease of finishing.

Hole patterns: round, square, slot, and special shapes

Hole geometry affects appearance and performance:

- Round holes — the most common, balanced appearance, predictable open area calculations.

- Square and hexagon holes — provide a modern, geometric aesthetic and can deliver slightly higher open area for the same pitch.

- Slots — excellent for directional airflow and architectural linearity.

- Special shapes (cross, decorative, etc.) — used for unique aesthetics, branding, or specialized function.

Manufacturing and customization — why it matters

One of the biggest advantages of custom perforation is control. You can specify thickness, material, hole diameter, pitch, and finished open area precisely to meet daylight, ventilation, and structural needs. For single-unit prototypes or large production runs, look for suppliers who support both one-piece orders and scalable manufacturing — that flexibility reduces waste and shortens lead times for pilot assemblies.

Practical selection checklist

Use this quick checklist when specifying perforated aluminum:

- What percentage open area do you need for daylight/ventilation?

- Is visual screening or privacy a priority?

- Will the panel face a corrosive environment? (choose suitable material)

- How visible is the panel from close range — do you need fine patterns or larger holes?

- Do you need acoustic properties (consider micro-perforation and backing materials)?

- Can you accept custom sizes and thicknesses? (custom options reduce field modifications)

Conclusion

Open area is the single most influential variable when designing perforated aluminum panels for light and ventilation. By combining the right open area percentage with suitable hole geometry, material, and panel thickness, you can fine-tune daylight quality, airflow, and overall performance for almost any architectural or industrial need.

Call to action

If you’d like help selecting the best open area and perforation pattern for your project — from one-off samples to large production runs — contact us at info@perfsheet.com. We offer custom sizes, multiple materials, and flexible minimums to match project needs.