Why surface oxidation matters for 3003 aluminum

3003 is a widely used, manganese-alloyed aluminum grade valued for excellent formability, reasonable corrosion resistance, and cost effectiveness. Like all aluminum alloys, 3003 forms a very thin, natural oxide layer (aluminum oxide, Al₂O₃) almost immediately when exposed to air. That thin film is protective — it’s an important first line of defense against further oxidation and many common environments.

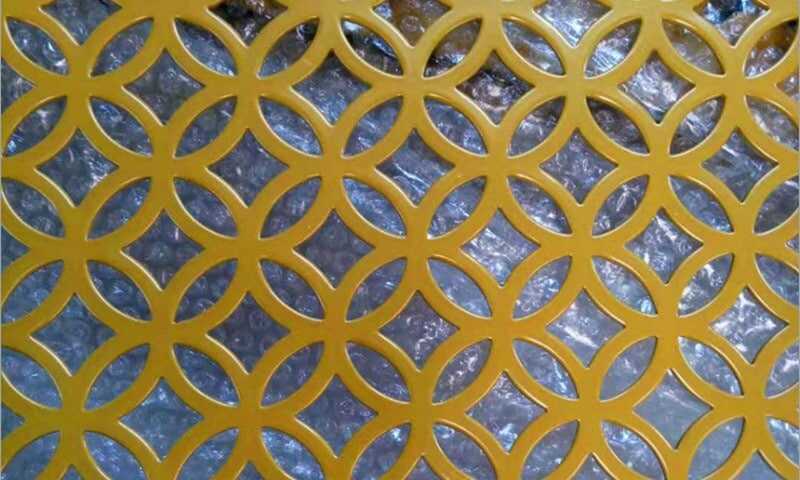

For perforated sheets, however, the metal geometry changes how contaminants and moisture behave: holes, edges, and cut perimeters create extra surface area and potential sites for dirt and residues to collect. So while the base alloy helps, the real-world performance often depends on surface treatment, coating choice, and how the perforated panel is applied and maintained.

Common surface treatments and their anti-fouling benefits

Natural oxide (as-cut, untreated)

- What it is: the thin Al₂O₃ layer that forms naturally.

- Benefits: immediate corrosion inhibition without added cost; retains aluminum’s natural matte look.

- Limits: because the oxide is extremely thin (nanometers), it offers limited long-term protection in aggressive or coastal environments and does little to prevent organic staining or dirt adhesion on perforated geometries.

Anodizing

- What it is: an electrolytic process that thickens and hardens the oxide layer under controlled conditions.

- Benefits: increases surface hardness, abrasion resistance, and chemical stability; improves adhesion for dyes and some topcoats; creates a more uniform, easy-to-clean surface than bare aluminum.

- Practical note: for perforated sheets, ensure anodizing is applied with attention to through-holes — good process control prevents uneven coloration and ensures consistent oxide thickness on hole edges.

Powder coating and liquid paint systems (including PVDF)

- What they are: polymer coatings applied over the aluminum to create a continuous barrier. PVDF (polyvinylidene fluoride) finishes are premium options for architectural use.

- Benefits: excellent anti-fouling performance when properly applied; colors and textures available; reduced surface energy (depends on coating) helps runoff and cleaning.

- Practical note: coating the inside of small perforations can be challenging — request manufacturer confirmation that the coating reaches inner edges and maintains adhesion without clogging holes.

Conversion coatings & clear sealants

- What they are: thin chemical films (e.g., chromate conversion, non-chromate alternatives) or clear sealers applied to improve paint adhesion and corrosion resistance.

- Benefits: typically used as primers or where preserving metallic appearance is important. Some modern, non-chromate chemistries offer improved environmental profiles.

Hydrophobic / nanocoatings

- What they are: thin surface treatments that increase water repellency and can reduce the tendency of dirt to stick.

- Benefits: can be useful for facades and exposed installations to encourage self-cleaning; often applied as an after-treatment to anodized or coated surfaces.

- Practical note: longevity varies by product and exposure; these are best used as part of a maintenance plan, not as a single permanent fix.

How perforation design affects fouling and cleaning

The perforation pattern, hole size, and open area (percentage of open surface) change how dirt and moisture behave on a panel:

- Hole diameter and shape: larger holes and simple round punches are typically easier to rinse through and less likely to trap fine particulates than very small, intricate hole shapes.

- Open area: higher open area reduces flat surface where dust settles, but also means more edges and potential for debris lodgment. Balance is key — match the pattern to the application.

- Pattern layout (staggered vs. straight): both patterns have structural and aesthetic tradeoffs; choose based on airflow, sightline, and cleaning access requirements.

- Edge quality and deburring: clean cut edges and proper deburring reduce crevices where contaminants can accumulate.

When specifying perforated 3003 panels for environments where fouling is a concern (urban pollution, near-shore salt spray, industrial dust), discuss hole size, pattern and finish with the supplier so samples can be tested in situ.

Environment-based selection guide

- Indoor architectural or decorative use: bare 3003 with clear anodizing or light powder coat is often sufficient. Focus on finish aesthetics and easy-clean coatings.

- Outdoor urban façades: consider anodizing plus a clear hydrophobic treatment, or a robust PVDF coating for long-term color stability and anti-staining.

- Coastal or industrial exposure: prioritize thicker anodic films or protective polymer coatings; plan for routine rinse maintenance to remove salt and corrosive deposits.

- Food processing or sanitary areas: specify compatible coatings and avoid surface chemistries that can trap residues; design panels for easy wipe and wash access.

Cleaning, maintenance and field care tips

- Use mild, non-abrasive detergents and fresh water for regular cleaning.

- Avoid strong chloride-based bleaches and highly alkaline cleaners that can accelerate corrosion on aluminum if misused.

- For painted or powder coated finishes, follow coating manufacturer instructions — most require only low-pressure washing and soft brushes.

- Rinse coastal installations with freshwater at scheduled intervals to remove salt deposits.

- Inspect edges and fastener points — these are common sites for early wear or contamination collection.

Testing and quality checks before purchase

Before committing to large orders, request:

- Finish samples: small perforated samples with the requested anodize/coating and hole pattern.

- Adhesion and salt spray data: coating suppliers can provide standard test reports (e.g., ASTM adhesion/salt spray tests) where applicable.

- Visual inspection: examine edge quality, presence of burrs, and uniformity of the finish on punched edges.

These steps help ensure the chosen surface treatment will meet on-site performance and maintenance expectations.

Practical takeaway for buyers

Choosing the right combination of material (3003), perforation pattern, and surface treatment (anodize, powder coat, PVDF, sealant, or hydrophobic topcoat) determines how well a perforated panel resists staining and fouling. For many projects, anodizing plus periodic rinsing strikes a balance between cost and durability; for high-exposure or color-critical applications, select PVDF or robust powder coating and confirm coverage inside holes and along cut edges.

If you’d like samples, finish options, or a custom quote for 3003 aluminum perforated panels tailored to a specific hole pattern, thickness, or finish, please contact us at: info@perfsheet.com. We can supply perforated samples with your chosen finish, support one-piece orders as well as large production runs, and provide technical guidance for coastal or high-pollution environments.