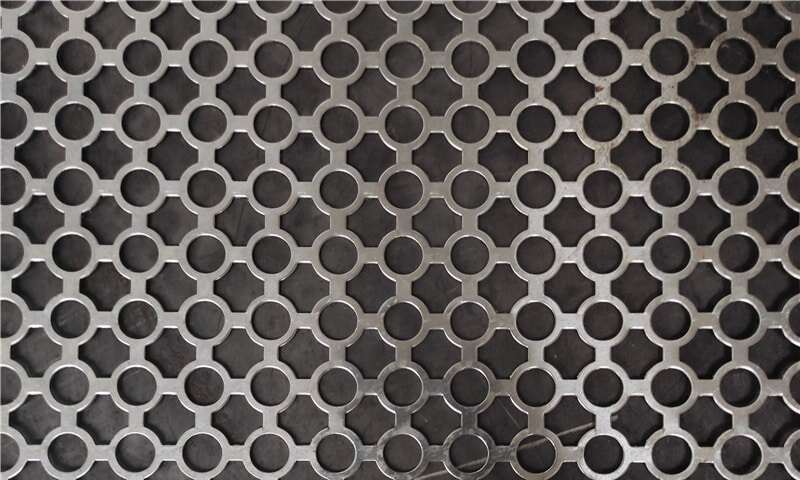

Among various types of perforated metal sheets, the 3003 aluminum perforated sheet has become one of the most popular materials in both architectural and industrial fields. Its combination of excellent corrosion resistance, formability, and attractive appearance makes it a preferred choice for designers, engineers, and fabricators around the world.

Superior Corrosion Resistance of 3003 Aluminum

The 3003 aluminum alloy contains manganese as its major alloying element, which significantly enhances its resistance to atmospheric corrosion. This means that even in humid, salty, or chemically active environments, 3003 aluminum perforated sheets maintain their strength and surface integrity over time.

Unlike untreated carbon steel perforated metal sheets or galvanized perforated panels, which may require periodic maintenance or coating, 3003 aluminum can naturally form a protective oxide layer that prevents further oxidation. This self-passivation property allows the material to stay bright and stable, even after years of outdoor exposure.

Comparison with Other Perforated Metals

When compared with stainless steel perforated sheets, 3003 aluminum is much lighter, offering about one-third of the weight while still delivering sufficient structural rigidity for most non-load-bearing applications.

For projects where weight reduction is crucial—such as ceilings, ventilation panels, or decorative facades—this feature provides clear advantages in both installation and cost efficiency.

In contrast to steel perforated grating or high manganese perforated sheets, aluminum options do not rust, even when exposed to moisture or air pollutants. This makes them ideal for marine, chemical, and food-processing environments where corrosion resistance is a top priority.

Typical Applications of 3003 Aluminum Perforated Sheet

Because of its durability, aesthetic flexibility, and lightweight nature, the 3003 aluminum perforated sheet finds wide use across multiple industries:

- Architectural design: Used for curtain walls, sunshades, ceilings, and decorative panels that require both visual appeal and weather resistance.

- Acoustic and ventilation systems: The perforated pattern allows airflow and sound control, commonly used in offices, theaters, and factories.

- Filtration and screening: Provides effective filtration while maintaining excellent resistance to moisture and chemicals.

- Transportation and machinery: Applied in vehicle components, protective guards, and machine enclosures for their anti-corrosion and lightweight properties.

If you are also interested in other patterns, you can explore related products such as round hole perforated sheet, hexagonal perforated metal, or micro perforated metal sheet, each offering distinct visual and functional features for custom applications.

Why Choose Custom-Produced Perforated Metal

For many projects, standard-size panels do not always fit the design or technical requirements. That’s why the ability to customize perforated metal sheets—in different hole shapes, thicknesses, materials, and open areas—is essential.

Whether you need aluminum, stainless steel, or galvanized perforated metal, customization ensures better precision, lower material waste, and a final product that perfectly matches your project’s vision. Flexible production also allows one-piece orders or large-scale manufacturing depending on your needs.

Conclusion

The 3003 aluminum perforated sheet combines excellent corrosion resistance, aesthetic versatility, and ease of fabrication, making it a reliable material for both indoor and outdoor applications. With proper customization options, it can serve in countless architectural, industrial, and decorative scenarios while maintaining long-term durability and visual appeal.

For more information or custom production inquiries, please contact us at info@perfsheet.com.