Introduction — why alloy selection matters for filtration hardware

For industrial filtration systems, the perforated carrier or support is a structural and contamination-control component, not just a decorative panel. Choosing between 304 and 316L stainless steel for round-hole perforated sheets affects corrosion resistance, maintenance frequency, weld integrity, and total cost of ownership. Drawing on twenty years working with filtration OEMs, fabricators, and end-users, this piece compares the two alloys with a focus on real-world filtration use cases and procurement criteria.

Round Hole Perforated Metal Sheets

Custom perforated metal sheets with precise hole patterns in various materials: stainless steel, aluminum, galvanized steel, carbon steel, copper, brass, and plastic. Durable and corrosion-resistant.

Perfect for architectural screens, machinery guards, acoustic panels, and decorative elements. Factory-direct pricing with cutting/bending services. Request quote or sample today.

Metallurgy at a glance: what’s different between 304 and 316L

Chemical drivers of corrosion resistance

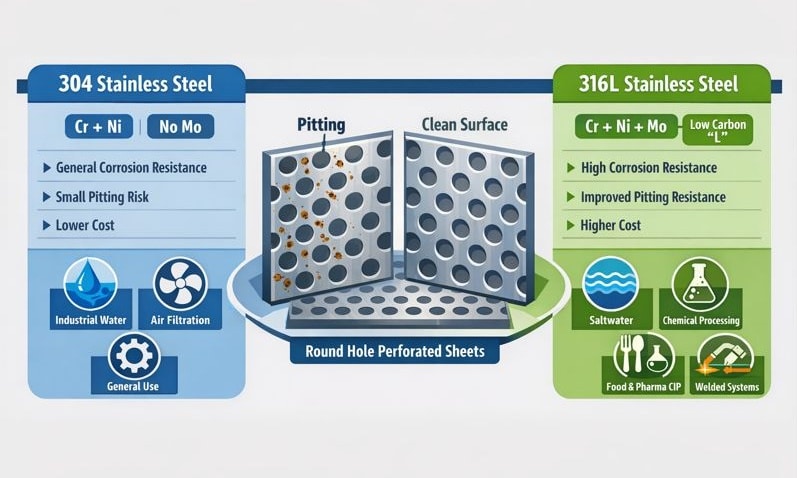

304 is a chromium-nickel austenitic stainless steel that offers broad general corrosion resistance in many process environments. 316L adds molybdenum and has lower carbon; molybdenum raises resistance to localized attack (pitting and crevice corrosion) in the presence of chlorides and halides, while the low-carbon “L” grade minimizes sensitization after welding.

What that means in practice

- Pitting/crevice: 316L outperforms 304 where chloride exposure is continuous or concentrated (seawater, brine, de-icing salts).

- Weld zones: 316L reduces intergranular corrosion risk after welding, which matters when perforated sheets are assembled into welded housings or frames.

- Fabrication: both punch and form well; 304 is marginally easier to draw in some extreme forming operations, but modern tooling handles both reliably.

Performance comparison for industrial filtration

Corrosion and contamination risk

In filters that contact saline slurries, process brines, or frequent chlorine-based cleaning, 316L delivers longer service life and lower contamination risk from corrosion byproducts. For dry air filters or low-chloride liquid filters, 304 is typically adequate and cost-efficient.

Cleaning, sanitization, and maintenance cycles

Repeated exposure to chlorine bleach, caustic cleaners, or high-pressure washdowns accelerates corrosion in 304. If the filtration maintenance regime uses aggressive chemicals or high-temperature clean-in-place (CIP), specify 316L or electropolished finishes to reduce fouling and extend intervals between replacements.

Mechanical and flow considerations

Hole diameter, pitch, open area percentage, and sheet gauge control hydraulic/airflow, structural stiffness, and clogging behavior. Material choice does not change open area, but it affects long-term dimensional stability under corrosion-fatigue and the need for protective finishes.

Cost and lifecycle analysis — capex vs. opex

Upfront vs. long-term cost

316L usually carries a market premium over 304 (market dependent), but the lifecycle view is decisive: in corrosive environments, lower maintenance, fewer shutdowns, and longer replacement intervals often make 316L the more economical choice over a 3–7 year horizon.

How to justify alloy selection in procurement

Use a simple total cost of ownership (TCO) model: initial material cost + installation + expected maintenance/replacement + downtime risk. For mission-critical filtration where failure causes contamination, process loss, or safety risk, the premium for 316L is frequently justified.

Specifying round-hole perforated sheets for filtration — practical guidance

Minimum procurement fields to include on the PO/RFQ

- Alloy: 304 or 316L (state “316L” explicitly if low carbon is required)

- Thickness (gauge) and tolerances

- Hole diameter (mm/in), pitch (center-to-center), pattern (staggered/straight)

- Open area (%) and clear flow area requirement

- Panel dimensions, bending/forming requirements, and flatness tolerance

- Finish: mill, brushed, or electropolished (specify Ra if needed)

- Welding instructions and post-weld treatment (if applicable)

- Traceability: material certificates (EN/ASTM), test reports, and surface inspection criteria

Finish and surface treatment considerations

Electropolishing improves corrosion resistance, reduces microbial harborage, and enhances cleanability — particularly important in food, pharma, or water treatment filtration. For general industrial filtration, a good mill or brushed finish is often adequate.

Selection checklist by filtration environment

Low-risk, indoor, non-chloride process fluids

Recommendation: 304 round-hole perforated sheets. Rationale: lower cost, adequate corrosion resistance, easy sourcing.

High-chloride, marine, or continuous brine contact

Recommendation: 316L with electropolish. Rationale: superior pitting resistance and cleaner weld zones.

Sanitary / CIP frequent cleaning (food, pharma)

Recommendation: 316L, electropolished, with documented material certificates and Ra requirements.

Conclusion — match alloy choice to exposure and risk

There is no universal “best” alloy; the right choice balances process exposure, maintenance policy, and budget. For many industrial filtration applications, 304 is the economical, sensible option. Where chloride exposure, aggressive cleaning, or welded assemblies are present, 316L reduces risk and often lowers lifecycle cost. When specifying Stainless Steel Round Hole Perforated Sheets, prioritize a complete technical spec and include lifecycle assumptions so vendors can price accurately and recommend fit-for-purpose finishes.