The 430 stainless perforated sheet is an economical choice for architects, fabricators, and buyers who need an attractive metal product without the premium cost of higher-grade stainless steels. In many projects, choosing the right material balances budget, appearance, and performance — and 430 stainless perforated sheet often hits that sweet spot.

Why 430 Stainless Is Cost-Effective

The primary cost advantage of 430 stainless perforated sheet comes from its material composition. Compared with austenitic grades, 430 is a ferritic stainless steel with lower nickel content, which significantly reduces raw material cost. Fabrication and finishing are straightforward, and production lines can efficiently punch and bend large panels, lowering labor and processing expenses for both small and large orders.

Manufacturing and Customization Savings

If your project requires custom hole patterns, varied thicknesses, or non-standard panel sizes, flexible production is essential.

We offer made-to-order options that allow one-piece minimums as well as bulk production runs. That flexibility avoids waste and reduces inventory costs.

For example, choosing optimized hole diameters or higher open areas can reduce material weight and cost while maintaining the desired visual effect of a perforated surface.

Practical Performance Trade-Offs

While 430 stainless perforated sheet provides good corrosion resistance for many indoor and mildly outdoor applications, it is not as corrosion-resistant as higher nickel alloys like 304.

For coastal or chemically aggressive environments, consider alternatives such as galvanized perforated metal sheet or stainless steel perforated sheet.

For decorative interiors, 430 often delivers the ideal balance between cost and finish.

Design and Decorative Applications

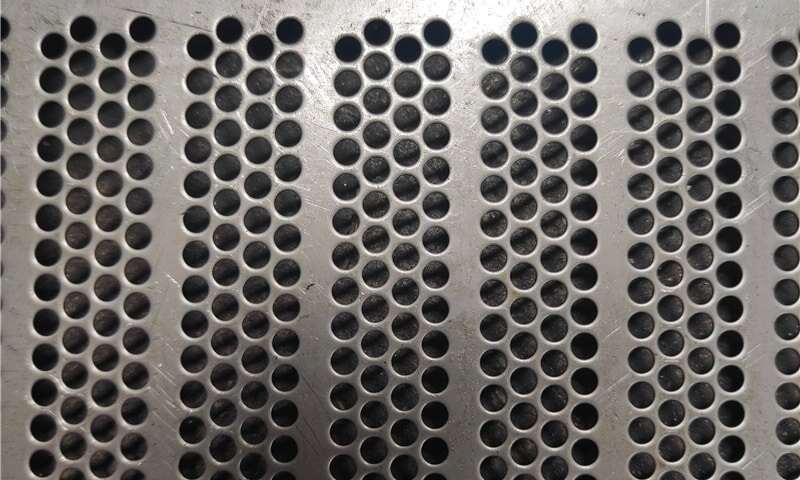

Designers appreciate 430 stainless perforated sheet for its clean surface, consistent hole geometry, and ability to be formed into panels, screens, ceilings, and partitions.

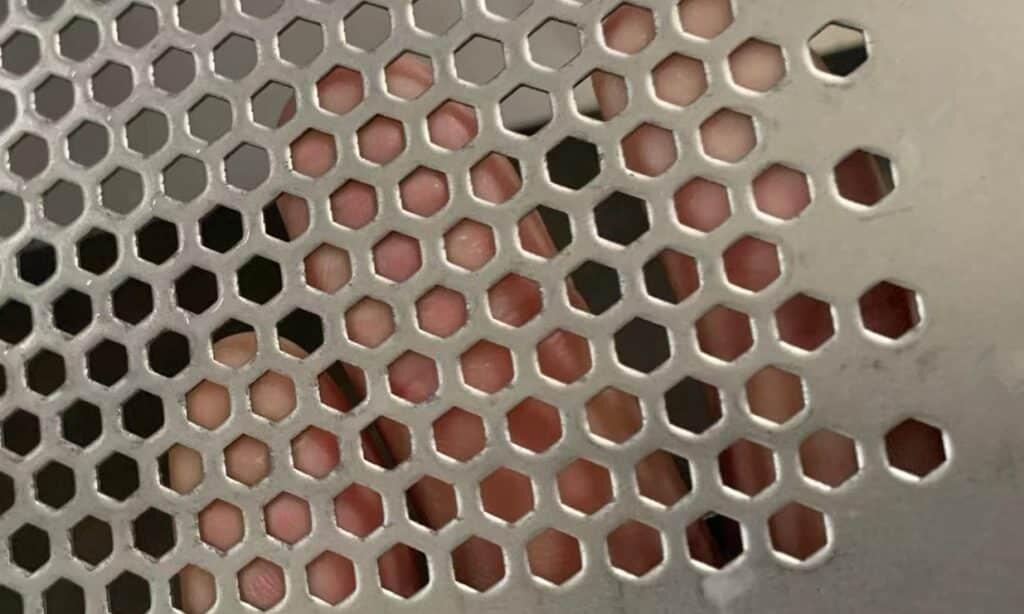

Popular patterns include round holes, square holes, and hexagonal openings.

You can pair a round hole perforated metal sheet with backlighting for a refined effect, or use a square hole perforated metal sheet for a more geometric appearance.

Interior uses include reception screens, acoustic panels, radiator covers, and light diffusers.

Exterior uses may include sunshades and decorative cladding where corrosion risk is moderate.

For safety or load-bearing applications, consider Perforated Safety Grating, which combines structural strength with visual appeal.

Optimizing Cost Through Material and Pattern Choices

To maximize value when using 430 stainless perforated sheet, consider these tips:

- Choose the smallest thickness that still meets strength needs.

- Select hole diameters and pitch that balance open area and rigidity.

- Use standard sheet sizes to reduce cutting waste.

- For large runs, consider coil production to lower per-unit cost.

Finishing Options and Aesthetics

430 stainless can be supplied in brushed, polished, or dull mill finishes.

A brushed finish is popular for interiors because it hides fingerprints and creates a soft sheen.

It can also be powder-coated or painted to match design schemes — just ensure proper surface preparation for adhesion.

Sustainability and Lifecycle Cost

Using 430 stainless perforated sheet can also be a sustainable choice.

Stainless steels are 100% recyclable, and lighter perforated panels reduce shipping impact.

When considering the lifecycle cost, the initial savings of 430 often outweigh higher up-front costs of premium grades for many applications.

Ordering and Lead Times

We support small prototype orders as well as large-scale production.

Our facilities can produce various hole types, such as hexagon hole, slotted hole, and micro perforated sheet, helping designers select patterns that meet both aesthetic and acoustic requirements.

Conclusion

For many decorative and semi-exposed uses, the 430 stainless perforated sheet offers a powerful combination of cost-effectiveness, formability, and visual appeal.

By selecting the right thickness, hole pattern, and finish, architects and fabricators can create budget-friendly designs that stand the test of time.

Contact and Samples

If you would like a quote or sample, email us at info@perfsheet.com.

Our team can help specify the most suitable 430 stainless perforated sheet for your project requirements.