A Carbon Steel Perforated Metal Sheet combines strength, versatility, and cost-effectiveness. Widely used across industrial and architectural projects, this material offers a reliable solution for screening, ventilation, filtration, decorative facades, and safety applications.

Key Advantages

- Strength and Durability

A Carbon Steel Perforated Metal Sheet delivers high tensile strength and excellent load-bearing capacity, making it suitable for structural panels, stair treads, and safety guards. Its durability helps resist deformation under heavy use. - Cost Efficiency

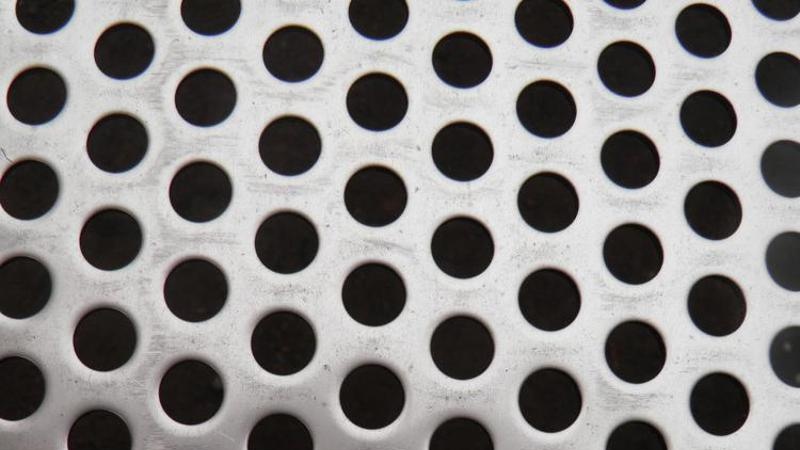

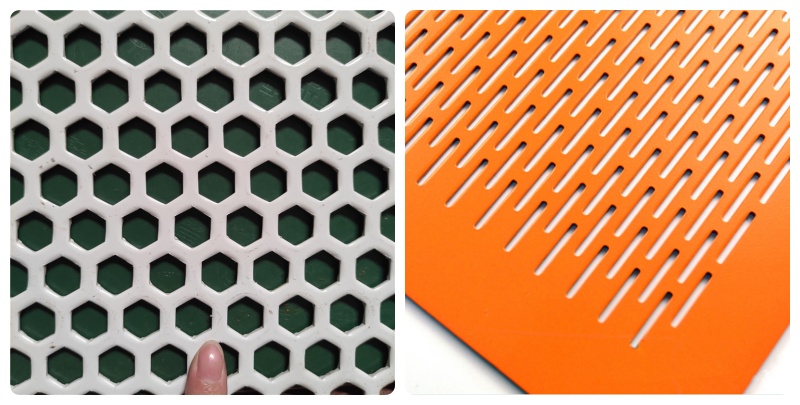

Compared with stainless steel or specialty alloys, a Carbon Steel Perforated Metal Sheet is more economical while still offering acceptable corrosion resistance when properly finished. This makes it a preferred choice for large-area installations where budget matters. - Customizable Patterns and Open Area

Manufacturers can produce round, square, hex, slot, and decorative patterns to meet airflow, light transmission, and aesthetic requirements. Adjusting hole size and pitch allows precise control of the open area percentage for filtration and acoustic tuning. - Easy Fabrication and Welding

Carbon steel accepts common fabrication processes—cutting, bending, welding, and finishing—so panels can be integrated into frames, enclosures, and complex assemblies with minimal additional cost. - Finish Options for Corrosion Protection

To improve weather resistance and longevity, finishes such as galvanizing, powder coating, and oil-based primers are commonly applied to carbon steel perforated sheets. These finishes expand the range of environments where the material performs well.

Typical Applications by Industry

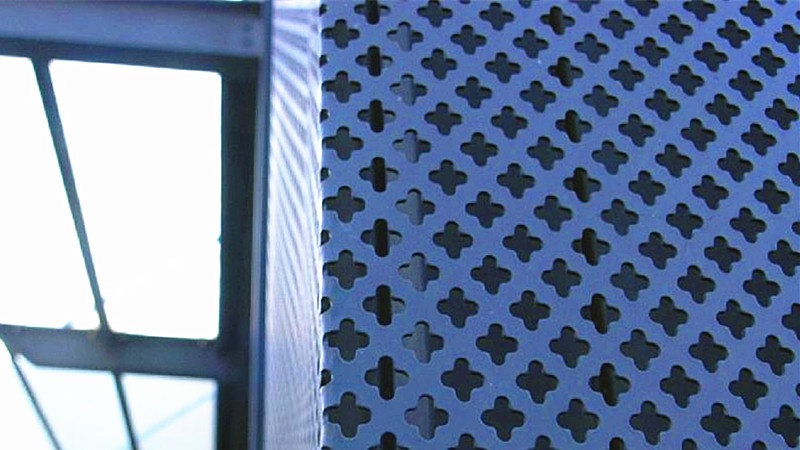

Architecture & Façade Design

Designers use Carbon Steel Perforated Metal Sheet for sunscreens, cladding, and decorative screening because it balances transparency and structural integrity. The sheet can be shaped into curved facades or layered to create dynamic visual effects.

HVAC & Ventilation

Perforated sheets control airflow and protect equipment in HVAC systems. By selecting the right hole pattern and open area, engineers achieve desired pressure drops and sound attenuation while maintaining strength.

Filtration & Separation

From coarse screening in mining to fine pre-filters in industrial processes, carbon steel perforated panels are used where mechanical strength is required alongside controlled particle passage.

Automotive & Transportation

Used for grille inserts, engine guards, and acoustic panels, Carbon Steel Perforated Metal Sheet provides a cost-effective option where impact resistance and formability are necessary.

Acoustics & Noise Control

Perforated liners combined with absorptive backing reduce reverberation in auditoriums, studios, and industrial plants. The tailored open area helps tune the frequency response for better sound control.

Agriculture & Food Processing

Durable and easy to clean when finished properly, perforated carbon steel finds use in sieving, drying beds, and machine guards in agricultural and food-processing equipment.

Safety & Stair Treads

Open, slip-resistant patterns on steel plates make ideal stair treads, walkways, and anti-slip platforms, delivering both traction and structural support.

Design Tips and Manufacturing Considerations

- Select thickness and hole pattern based on load and appearance requirements.

- Consider corrosion protection early: hot-dip galvanizing or powder coating can extend service life dramatically.

- Optimize nest layout to minimize waste when cutting perforations.

- Prototype critical panels to verify acoustic, airflow, and structural performance before mass production.

Suggested Specifications (common ranges)

- Material grades: commercial low-carbon steels (e.g., ASTM A36 equivalents)

- Thickness: 0.5 mm — 12 mm depending on application

- Hole diameters: 1 mm — 50 mm

- Open area: 5% — 60%

A Carbon Steel Perforated Metal Sheet is a versatile, cost-effective material with broad application across architecture, industry, and transport. With the right pattern, finish, and fabrication approach, it meets functional needs while offering attractive aesthetics for modern projects.