Introduction

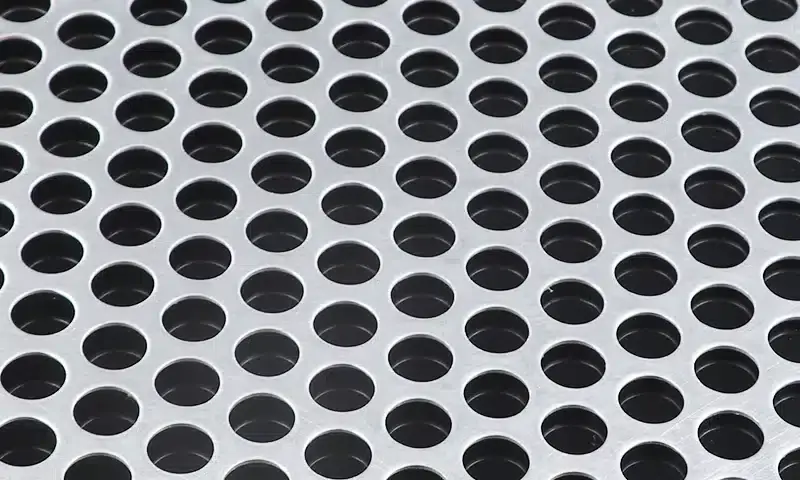

In modern architecture and industrial applications, aluminum perforated metal sheets have become a highly versatile material. Their combination of light weight, corrosion resistance, and aesthetic appeal makes them ideal for building facades, ceiling panels, ventilation screens, soundproof walls, and decorative features. However, the surface treatment of aluminum perforated sheets plays a crucial role in their performance and durability.

At Anping Senchi Metal Wire Mesh Products Co., Ltd., we specialize in the customized production of perforated metal sheets in various materials, including carbon steel, galvanized steel, stainless steel, high manganese steel, and aluminum. Our factory provides flexible customization of hole shape, size, thickness, and open area according to clients’ needs.

Why Surface Treatment Matters for Aluminum Perforated Metal Sheets

Aluminum itself is naturally resistant to rust, but without proper surface treatment, it can still oxidize or lose its luster over time. A well-applied surface finish provides several benefits:

- Enhanced corrosion resistance – extending lifespan, especially in outdoor or humid environments.

- Improved appearance – anodized or coated surfaces look more uniform, decorative, and modern.

- Better adhesion – coatings improve bonding with paint and reduce peeling.

- Increased surface hardness – protecting from scratches and mechanical wear.

Whether used in construction, transportation, or filtration, choosing the right surface treatment for aluminum perforated sheets ensures both functional performance and visual impact.

Common Surface Treatment Methods

1. Anodizing Treatment

Anodizing is one of the most widely used surface treatments for aluminum. It is an electrochemical process that forms a thick, hard oxide layer on the surface of the metal, which enhances both corrosion resistance and aesthetic value.

Process Overview:

- The aluminum sheet is cleaned and placed into an acid electrolyte bath.

- Electric current passes through the solution, creating an oxide film.

- The surface can be dyed in various colors or left natural silver-gray.

Advantages:

- Excellent corrosion and UV resistance.

- Non-peeling surface (the film is part of the metal itself).

- Elegant matte or satin finish.

- Environmentally friendly—no volatile chemicals.

Applications:

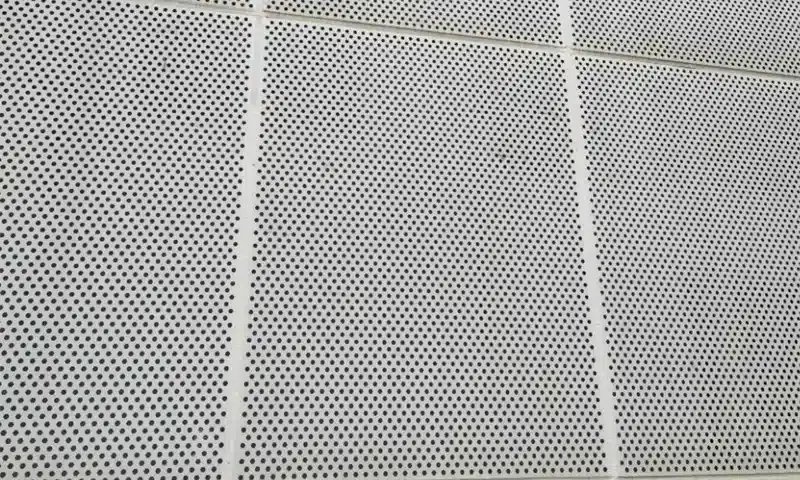

- Architectural facades

- Ceiling panels

- Furniture design

- Decorative partitions

For projects where appearance and long-term durability are important, anodized aluminum perforated panels are a smart choice.

2. Powder Coating (Spray Coating)

Another popular option is powder coating, also known as spray coating. It involves applying dry, electrostatically charged powder paint onto the aluminum surface, followed by curing under heat to form a protective, decorative layer.

Key Features:

- Wide color selection: RAL color charts available.

- Strong adhesion and resistance to UV and chemicals.

- Even coating with high thickness control.

- Better impact and scratch resistance than ordinary liquid paint.

Applications:

- Interior wall panels

- Outdoor furniture

- Industrial enclosures

- Decorative perforated cladding

Powder-coated aluminum perforated sheets combine aesthetics and functionality, offering a long-lasting, color-stable surface for both indoor and outdoor applications.

Maintenance Tips for Aluminum Perforated Metal Sheets

To maintain the long-term appearance and performance of your aluminum perforated metal sheets, follow these basic maintenance guidelines:

- Regular Cleaning

Use mild soap and water with a soft cloth or sponge. Avoid abrasive materials or acidic cleaners that may damage the surface. - Inspection for Damage

Check periodically for scratches, dents, or signs of corrosion, especially in outdoor installations exposed to rain and salt. - Protect from Harsh Chemicals

Avoid contact with strong alkaline or acidic solutions. These can affect the anodized or coated layer. - Re-Coating When Necessary

In long-term projects, re-anodizing or re-coating may be applied to refresh the appearance and strengthen protection.

By implementing proper care, your aluminum perforated panels will retain their original beauty and structural integrity for many years.

Applications and Related Perforated Metal Products

Aluminum perforated sheets are widely used across various industries. Typical applications include:

- Building facades and curtain walls

- Acoustic wall panels and ceilings

- Sunshade systems

- Decorative furniture elements

- Machine guards and ventilation screens

Conclusion

Proper surface treatment and maintenance significantly enhance the performance and lifespan of aluminum perforated metal sheets. Whether through anodizing for elegant corrosion resistance or powder coating for colorful durability, the right finish ensures your project achieves both beauty and functionality.

At Anping Senchi Metal Wire Mesh Products Co., Ltd., we are committed to delivering high-quality perforated metal sheets tailored to your specifications—whether you need unique patterns, customized materials, or special coatings.

📍 Contact us for your next project:

- Company: Anping Senchi Metal Wire Mesh Products Co., Ltd.

- Address: East Industrial Zone, Anping County, Hebei Province, China

- Website: https://perfsheet.com

- Email: info@perfsheet.com