Choosing the right Carbon Steel Perforated Metal Sheet is crucial for performance, safety, and aesthetics. Whether you are specifying panels for façade applications, industrial filtration, acoustic screens, or stair treads, understanding how thickness, hole geometry, and surface treatment interact will save time and cost.

Carbon steel offers strength, cost-effectiveness, and excellent formability. A Carbon Steel Perforated Metal Sheet provides structural stiffness while allowing airflow, light, or drainage. Its mechanical properties make it a popular choice where durability is required.

Key selection factors

1. Required thickness and load-bearing capacity

Thickness defines weight, rigidity, and load capacity. For light screening or decorative facades, thin carbon steel sheets (e.g., 0.8–2.0 mm) are common. For heavy-duty flooring, steps, or machine guards, thicker plates (3.0 mm and above) are recommended. Specify the Carbon Steel Perforated Metal Sheet thickness based on span, live load, and expected wear.

2. Hole pattern and geometry

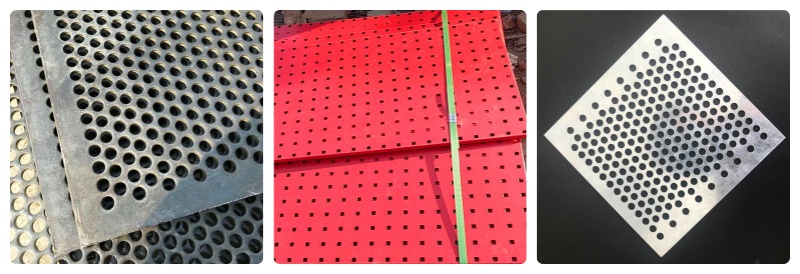

Hole size, shape, and pitch affect open area, strength, and appearance. Standard patterns include round, square, hexagon, slot, and decorative shapes. Round holes preserve more structural integrity; elongated slots or large decorative perforations increase flexibility and visual openness. When designing, calculate open area percentage and consider how the hole geometry changes tensile and compressive behavior. Use sample panels to evaluate acoustic and light transmission. Mention the Carbon Steel Perforated Metal Sheet hole pattern on drawings and shop tickets.

3. Edge condition and fabrication tolerance

Edges can be cut, sheared, or laser-finished. Burr-free edges and consistent hole tolerance prevent installation problems. Ask for tolerance charts and inspection reports when ordering larger runs. For welded assemblies, ensure the selected Carbon Steel Perforated Metal Sheet can be formed and welded without cracking.

4. Surface treatment and corrosion protection

Bare carbon steel rusts quickly in outdoor or humid environments. Common protective options include hot-dip galvanizing, zinc electroplating, powder coating, and specialized primers. Choose hot-dip galvanizing for long-term outdoor exposure; choose powder coating when color matching and decorative finish are required. For combined protection, galvanized + powder-coated systems provide both corrosion resistance and aesthetic longevity. Specify the expected environment to select the appropriate treatment for your Carbon Steel Perforated Metal Sheet.

5. Manufacturing methods and lead time

Perforations can be produced by punching, laser cutting, or waterjet. Punching is economical for high-volume, consistent patterns; laser cutting is better for custom or low-volume runs and complex shapes. Clarify batch sizes and delivery expectations with your supplier. For urgent architectural projects, request lead-time confirmation and sample approvals. Choose the right production method for your Carbon Steel Perforated Metal Sheet to balance cost and precision.

6. Mechanical and structural testing

Request test certificates: tensile strength, yield, coating thickness, and adhesion tests for painted finishes. If the Carbon Steel Perforated Metal Sheet will be load-bearing, ask for third-party load testing or structural calculations. Keep records of material certifications to meet regulatory and safety audits.

Installation tips

- Allow for thermal movement and fastening methods that do not concentrate stress near perforations.

- Use backing or stiffening ribs where larger open areas reduce rigidity.

- Pre-drill mounting holes in solid regions or use self-drilling fasteners rated for steel.

Maintenance recommendations

Routine inspections, cleaning, and touch-up coatings extend service life. For exterior installations, clean salt deposits and inspect coatings annually. For industrial environments exposed to chemicals, select coatings resistant to the specific agents present.

Spec sheet checklist (what to include in your purchase order)

- Material grade and mill certificate

- Exact thickness and tolerances

- Hole pattern, size, pitch, and open area

- Surface treatment and required salt-spray or corrosion rating

- Edge finish and fabrication notes

- Quantity, dimensions, and delivery schedule

- Packaging and handling requirements

Common applications

Carbon Steel Perforated Metal Sheets are used in architecture (sunshades, facades), industrial filtration, sound attenuation, machine guards, stair treads, and decorative installations. Match the product variant to the performance need — for high-corrosion or hygienic needs, consider stainless alternatives; for cost-sensitive structural projects, carbon steel remains competitive.

Specifying the right Carbon Steel Perforated Metal Sheet comes down to matching thickness, hole type, and protection to the application. Work closely with your supplier to review samples, detailed drawings, and test certificates before full production. A well-specified panel minimizes site rework and ensures the long service life of your installation.

Contact us for custom patterns, samples, and technical assistance.