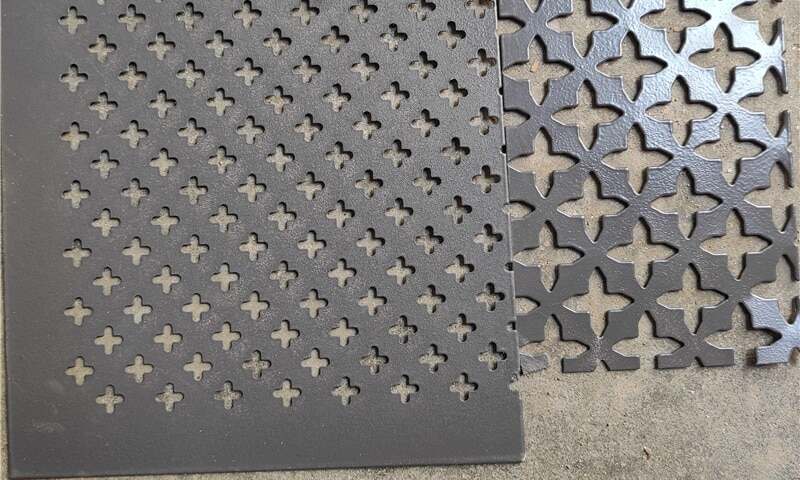

Cross-shaped perforated plates are widely used in architecture, industrial filtration, acoustic panels, and facades because of their distinctive pattern and functional open area. However, the same geometry that gives them strength and style — the multiple edges and cutouts — also exposes more metal surface and sharper edges to the environment, increasing corrosion risk. Choosing the right surface treatment is crucial to prolong service life, reduce maintenance, and keep finishing costs predictable.

Why cross-shaped geometry affects corrosion

Cross-shaped holes create narrow ligaments and sharp corners within each opening. These geometric features:

- Increase the total exposed edge length per unit area (more edges = more anodic sites).

- Make uniform coating deposition harder at hole edges and the inside of perforations.

- Can retain moisture, salt, and debris around the hole edges if drainage/airflow is poor.

Because of these factors, untreated or poorly finished cross-pattern sheets often begin to show edge-first corrosion. That’s why surface treatment choice and process control are more critical for cross-shaped perforated plate corrosion resistance than for smooth sheet products.

Common base metals and how they behave

Different substrates react differently to the same treatment:

- Mild steel / carbon steel — strong and economical but needs protective coatings (galvanizing, paint, powder coat, metal plating). Untreated steel corrodes quickly in humid or coastal environments.

- Stainless steel — inherently corrosion resistant thanks to chromium passivation, but cut edges and burrs can be locally vulnerable; passivation and polishing improve longevity.

- Aluminum — naturally forms a thin oxide layer; anodizing and appropriate coatings enhance durability and wear resistance.

When specifying finishes, start by matching the substrate to the environment (interior vs. exterior, coastal vs. industrial) and then choose the surface treatment to complement that substrate.

Surface treatment options and practical notes

1. Mechanical and pre-treatment steps (critical)

Before any coating, clean, deburr, and degrease. For perforated plates:

- Remove burrs at hole edges to ensure even coating and reduce stress concentrations.

- Use alkaline cleaning and rinsing; for steel, light pickling may be needed to remove mill scale.

Proper pre-treatment dramatically improves adhesion and uniformity of subsequent coatings.

2. Hot-dip galvanizing

A robust choice for carbon steel where corrosion protection is required:

- Provides a metallurgical zinc layer that protects by sacrificial action.

- For perforated plates, ensure racks/fixtures and adequate drainage during dipping to avoid pooling inside holes.

- Consider design for draining/tipping angles so the zinc layer deposits evenly.

3. Electroplating (zinc, nickel, chrome alternatives)

Electroplating can produce thinner, more uniform decorative finishes:

- Line-of-sight limitations mean edges and deep perforation interiors can get thinner coatings — plating setup and fixturing are important.

- Electroplating is suitable for decorative or light-duty protection; for heavy exposure, combine with topcoats.

4. Powder coating and liquid paint systems

Powder coat or wet paint provides a continuous barrier:

- Powder coating gives a tough, uniform finish but relies on excellent surface prep.

- For perforated patterns, electrostatic application can help, but inner hole areas may receive less coverage; rotating or jigging parts during coating improves consistency.

- Use corrosion-resistant primers (zinc-rich primers for steel) before topcoats in aggressive environments.

5. Anodizing (for aluminum)

Anodizing increases surface hardness and corrosion resistance:

- Produces an oxide layer integral to the aluminum substrate — good for both aesthetics and protection.

- Ensure that perforation edges are free of heat damage and contaminants before anodizing to avoid uneven appearance.

6. Passivation and conversion coatings (stainless and aluminum)

- Stainless steel passivation removes free iron and promotes a stable chromium oxide film. It’s a low-cost, high-value step for edge protection after cutting and forming.

- Conversion coatings (non-chromate chemistries, silane, cerium) can be applied to steel or aluminum as base layers to enhance adhesion for topcoats while meeting stricter environmental rules.

Achieving uniform protection on perforations — practical tips

Because perforated sheets are challenging to coat uniformly, follow these best practices:

- Design for finishing: specify hole sizes, spacing, and sheet orientation that facilitate drainage and coating access. If possible, avoid very tight stacks during coating.

- Fixturing / rotation: use fixtures that expose both sides evenly or rotate parts during coating to minimize shadowing.

- Multi-step systems: combine a corrosion-resistant base (e.g., galvanizing or primer) with a topcoat for aesthetics and additional barrier protection.

- Edge treatment: deburr and consider an edge-wrap or small fillet to reduce sharp corners that cut coatings thin.

- Sample testing: always test a sample of your exact perforation geometry through the full finishing process before committing large orders.

Inspecting and verifying corrosion resistance

To make sure the finish meets expectations, carry out standard checks:

- Visual inspection for coating continuity, runs, and thin spots around perforations.

- Adhesion tests (cross-cut or pull tests) on representative parts.

- Accelerated corrosion testing such as salt spray (industry reference) to compare finishes and predict field performance.

- Coating thickness measurement at edges and on flat areas to ensure minimum protective thickness is achieved.

Maintenance and lifecycle considerations

A well-applied surface treatment reduces maintenance but does not eliminate it. For long life:

- Design installations to avoid pooling water and to allow air circulation.

- Use sacrificial maintenance coatings for high-contact areas.

- Establish simple inspection schedules (visual checks after the first few months and yearly thereafter in harsh environments).

- Keep spare panels or small repair kits to treat localized damage quickly.

Choosing the right finish for your project

Match three inputs when you specify finishes:

- Environment: interior, exterior, coastal, chemical exposure.

- Aesthetics: visible architectural finishes may require anodizing or decorative plating + topcoat.

- Budget and life expectancy: hot-dip galvanizing plus paint costs more upfront but reduces lifetime maintenance.

For many outdoor architectural or industrial uses, a two-layer solution — a corrosion-resistant base (galvanize or primer) plus a topcoat (paint or powder) — provides a balanced answer for cross-shaped perforated plate corrosion resistance.

Conclusion

Cross-shaped perforated plates deliver distinctive looks and functional benefits, but their geometry raises unique finishing challenges. Thoughtful selection of pretreatment, coating system, and final inspection — together with design attention to drainage and edge quality — will dramatically improve corrosion resistance and lifespan. When these elements are combined, the result is reliable performance and lower total lifecycle cost.

If you’d like help selecting finishes for a specific project or need sample panels treated and tested, please contact us at info@perfsheet.com. We can provide material recommendations, finishing options, and small-run samples so you can verify performance before ordering in volume.