This is a practical, industry-focused introduction to stainless steel round-hole perforated sheets: why round holes are the most common pattern, how typical 304 and 316 stainless steels behave, the global dimensions and spec language buyers see, plus selection tips for filtration, architectural, and structural uses.

Quick overview

Round-hole perforated sheets are flat metal sheets with regularly spaced circular openings. They are widely used because the round geometry is simple to punch, structurally efficient, and visually neutral — making this pattern the go-to choice across filtration, acoustic panels, façade cladding, machine guards, and many industrial applications.

Key benefits at a glance

- Cost-effective production (simple tooling and high punch rates)

- Predictable open area and flow characteristics

- Good combination of strength and transparency (drainage, light, air)

- Clean, neutral aesthetics for architectural use

Round Hole Perforated Metal Sheets

Custom perforated metal sheets with precise hole patterns in various materials: stainless steel, aluminum, galvanized steel, carbon steel, copper, brass, and plastic. Durable and corrosion-resistant.

Perfect for architectural screens, machinery guards, acoustic panels, and decorative elements. Factory-direct pricing with cutting/bending services. Request quote or sample today.

Why round holes dominate the market

Round holes are the most popular perforation for several practical reasons:

- Manufacturing efficiency — Round punches and dies wear evenly and are easy to maintain. High press speeds and long tool life reduce unit cost compared with complex shapes.

- Strength & material economy — Circular holes preserve surrounding metal (no sharp corners where stress concentrates), so for a given open area round holes often allow thinner material or larger spans.

- Consistent flow & filtration — Circular openings give uniform flow behaviour and predictable particle passage for many filtration and screening tasks.

- Aesthetics & scalability — Round patterns scale cleanly across sizes and layouts (staggered or straight), making them suitable for seamless cladding and decorative panels.

- Versatility — Works across sheet metals, gauges, and finishes; easy to combine with secondary operations (bending, welding, polishing).

Common stainless steel grades: 304 vs 316 (what to choose and why)

For perforated sheets, 304 and 316 cover the majority of requirements. Below is a concise comparison in plain language.

304 (A2)

- Composition highlights: ~18% Cr, ~8% Ni.

- Corrosion resistance: Excellent in ordinary atmospheres, indoor and mildly corrosive outdoor environments.

- Strength: Good formability and weldability.

- Typical uses: General architectural panels, indoor screens, HVAC, machine guards, light filtration.

- Cost: Lower than 316.

316 (A4, often “marine grade”)

- Composition highlights: ~16–18% Cr, ~10–14% Ni, plus Mo (~2–3%) for enhanced pitting resistance.

- Corrosion resistance: Superior in chloride/sea/chemical environments; resists pitting and crevice corrosion better than 304.

- Strength & fabrication: Slightly less readily formed than 304 but still very workable; welds well with proper procedure.

- Typical uses: Coastal architecture, marine equipment, chemical plants, food processing near salt or halogens.

- Cost: Higher than 304 (premium for corrosion resistance).

Selection rule of thumb

- If the part will face salt, sea spray, chloride cleaning, or aggressive chemicals → choose 316.

- For general-purpose indoor/outdoor use without heavy chloride exposure → 304 is normally sufficient and more economical.

Global specifications & common sizes (what buyers expect)

Perforated sheet specs vary by market, but many buyers will see the same standard descriptors. Below are the terms and typical ranges.

Base material / grade

- “Stainless Steel 304 / 304L” or “Stainless Steel 316 / 316L”

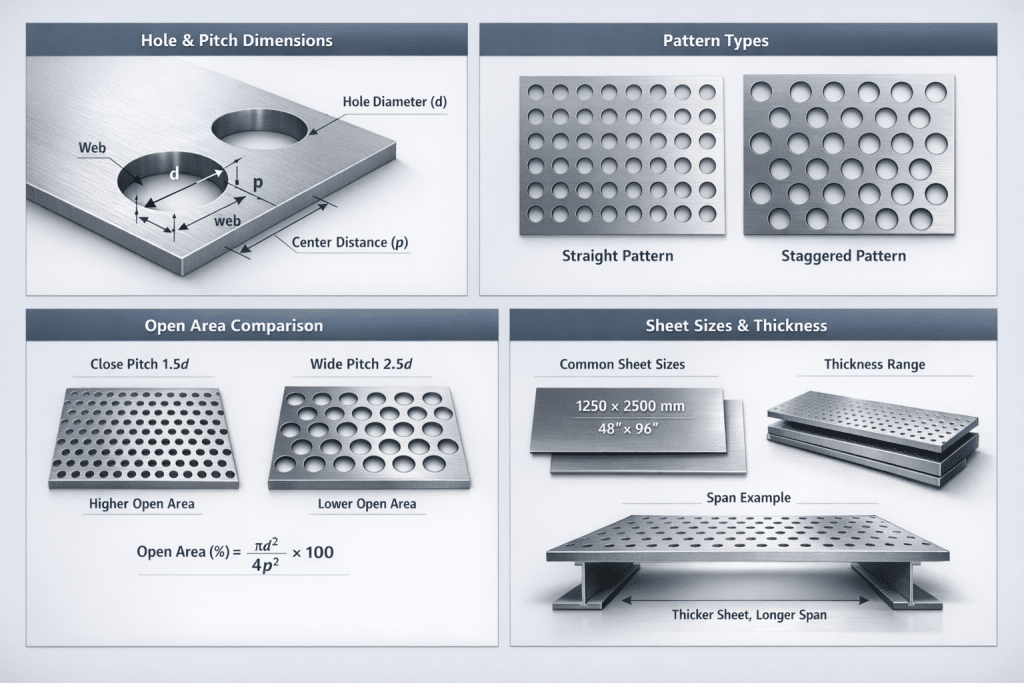

Sheet size (common nominal)

- Metric: 1220 × 2440 mm, 1250 × 2500 mm

- Imperial: 48″ × 96″ (4′ × 8′) — less precise dimensioning appears in supplier lists

(Custom sizes and cut-to-length available; many suppliers cut to final size)

Thickness (gauge / mm)

- Thin: 0.5 mm – 1.0 mm (light decorative, acoustic backing)

- Medium: 1.2 mm – 3.0 mm (general panels, filters, guards)

- Heavy: 3 mm – 10+ mm (structural, heavy filtration, load-bearing treads)

(Thickness choice depends on span, load, and application)

Hole diameter (d)

- Very small: 0.8 mm – 2.0 mm (fine filtration, decorative screens)

- Small/medium: 2 mm – 8 mm (airflow, light screening)

- Large: 8 mm – 25 mm+ (heavy screening, aesthetics, large-area flow)

Pitch / center-to-center distance (p)

- Described as “p = d + web” or simply “p = 10 mm” etc. Common ratio guidelines:

- Close-pitch: p ≈ 1.5×d to 2×d (higher open area, weaker web)

- Wide-pitch: p ≥ 2.5×d (stronger web, lower open area)

Patterns

- Straight (square) pattern: holes in columns and rows — easier to layout and calculate.

- Staggered (triangular) pattern: rows offset — increases open area for the same d and p and improves rigidity in some directions.

Open area (how transparent the sheet is)

- For a square pattern, approximate open area (%) = (π × d²) / (4 × p²) × 100.

- Example: d = 5 mm, p = 10 mm → open area ≈ 19.6%.

- Staggered patterns typically increase open area by ~10–20% compared with square patterns for the same d and p (exact value depends on geometry).

Tolerances

- Punching tolerances commonly ±0.1 mm to ±0.3 mm depending on hole size and material thickness; tighter tolerances add cost.

Typical finishes and secondary treatments

- Mill finish — as-rolled surface; economical, suitable for many industrial uses.

- Brushed (No. 4) — popular for architectural panels with a satin look.

- Polished (No. 8 mirror) — high-end aesthetics and ease of cleaning.

- Passivation — chemically removes free iron and improves corrosion resistance; recommended for most stainless parts after fabrication.

- Electropolishing — smooths micro-peaks, improves corrosion resistance and cleanliness for food/medical use.

- Edge treatment — deburring, hemmed edges, or edge folding for safety and stiffness.

Manufacturing notes (what affects lead time & cost)

- Punching vs laser — Round holes are normally produced by punching (fast, low cost); laser/CNC used for prototypes or small volumes with complex layouts.

- Tooling — standard round punches are inexpensive; custom diameters or very large holes may need special tooling.

- Nest efficiency & yield — sheet layout determines material utilization; staggered patterns can improve yield for some sizes.

- Batch size — unit cost falls quickly with larger runs because tooling and setup costs are fixed.

- Thickness & hole size interplay — as thickness increases, the slug-ejection and burr control become more complex; heavier gauges can need larger punch force and different tooling.

How to choose the right spec (practical checklist)

- Environment — indoor or coastal/chemical? 304 usually; 316 for chlorides/chemicals.

- Function — airflow, filtration, acoustic, decorative, tread? Define target open area and hole size.

- Mechanical needs — what span or load must the sheet support? Choose thickness and consider stiffening (flanges, folds).

- Aesthetics — brushed or mirror finish? Straight or staggered pattern? Hole size spacing affects visual scale.

- Cleanability — food/medical → electropolished + passivation recommended.

- Budget & lead time — punching round holes is cost-effective; tight tolerances and specialty finishes increase price.

Sample specification template (copy and adapt)

Material: Stainless steel 316L, sheet condition: annealed and cold-rolled.

Sheet size: 1250 × 2500 mm, or cut to 610 × 2440 mm.

Thickness: 2.0 mm.

Pattern: Round holes, staggered (triangular) pattern.

Hole diameter (d): 5.0 mm. Pitch (p): 10.0 mm (center-to-center).

Open area: approx. 19.6% (square pattern reference); confirm for staggered.

Finish: No. 4 brushed finish, passivated.

Tolerances: ±0.15 mm on hole diameter; ±1.5 mm on overall dimensions.

Edge treatment: deburred and hemmed on all edges.

Quantity: 200 sheets, delivery to [destination], lead time X weeks.

Common applications & example specs

- Acoustic panels — small holes (1–3 mm), high open area backing, decorative finish.

- HVAC & diffusers — medium holes (3–10 mm), moderate open area, 304 usually.

- Machine guards & safety screens — larger holes for visibility (6–20 mm), thicker steel for rigidity.

- Architectural cladding & façade — varied hole sizes for visual effect, 316 in corrosive climates, brushed/polished finish.

- Filters & sieves — very specific hole sizes and tolerances; often paired with backing mesh or welded frames.

- Food processing — 316, electropolished, and passivated for hygiene.

Frequently asked questions

Q: Can perforated stainless be welded?

A: Yes — standard welding practices apply. Use matching filler and consider distortion control; post-weld passivation is recommended.

Q: Is stainless perforated sheet suitable for outdoor use?

A: Yes — 304 is fine for most non-marine outdoor locations; for seaside or chloride exposure, choose 316.

Q: How does hole size affect strength?

A: Larger holes or closer pitch reduce the residual web and lower stiffness. If the panel carries load, increase thickness or add stiffening.

Q: Which pattern gives more open area, straight or staggered?

A: Staggered (triangular) patterns typically provide higher open area for a given d and p than straight (square) patterns.