We provide a capability overview for heavy-duty perforated plates used in heavy industry and infrastructure applications. Our manufacturing focus is thick-gauge punched plate designed for long service life under high loads, abrasion and cyclic stress. For full product specs and standard factory options, see heavy duty perforated plate manufacturer.

Heavy Duty Perforated Plates

Need a thick perforated plate made to drawing? Our program supports 2.75–30mm thickness, up to 6000×1500mm, with round/square/hex/slotted patterns, plus cut-to-size and surface protection for industrial installations.

Thickness & tolerances

Thickness range and flatness control are the starting point for heavy-duty applications. Typical capability summary:

- Nominal thickness: 2.75–30 mm (specify mm in RFQ).

- Typical manufacturing tolerance: ±0.1–0.5 mm depending on thickness and material.

- Recommended allowance for machining or forming: add 0.5–1.5 mm where further processing is needed.

Sheet width and length

Sheet dimensions determine yield and handling. Common factory ranges and considerations:

- Maximum coil/plate width: up to 2500 mm (custom widths on request).

- Standard usable lengths: single-sheet lengths to 12,000 mm (longer lengths by arrangement).

- Plate edge condition: mill-edge, shear-edge, or laser/trimmed as specified in the purchase order.

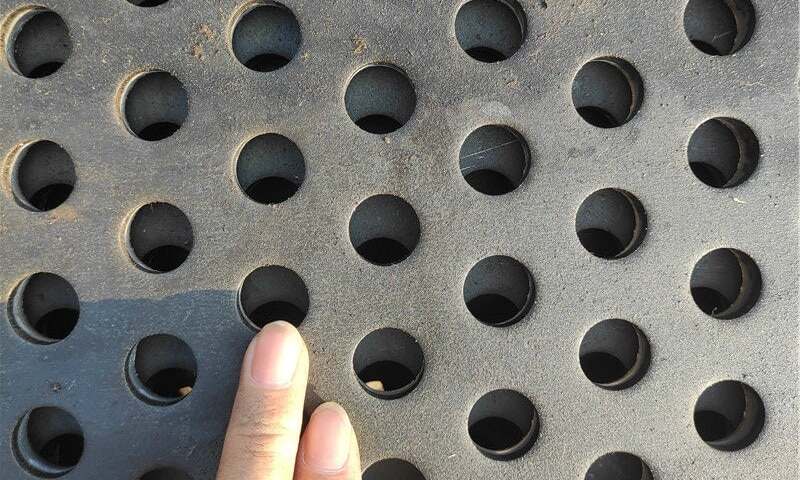

Hole patterns, sizes & open area

Hole geometry drives performance—pressure drop, structural strength, and wear distribution. Engineers typically specify:

- Hole shapes: round, square, slotted (elongated), oblong, or custom-shaped.

- Hole size range: from sub-millimeter (fine screens) up to 50+ mm for structural screens.

- Pattern types: straight-line (inline) or staggered (offset) to optimize strength and open area.

- Pitch and material retention: specify minimum edge distance to avoid tear-out under load.

- Open area considerations: higher open area reduces weight and allows flow, but reduces stiffness—balance by selecting thicker gauges or smaller pitch.

Fabrication methods & secondary processing

How a plate is manufactured affects edge condition, hole accuracy and residual stresses:

- Punching (turret/CNC) for high-throughput standard patterns.

- Laser / waterjet for small volumes or complex hole shapes.

- Coining or embossing where dimensional accuracy or burr reduction is critical.

- Secondary work: CNC trimming, notching, welding, stiffening ribs, countersinking, and tapping.

Flattening, stress relief & quality control

Thick plates often need flattening and stress-relief processes to meet installation tolerances:

- Shot peening or thermal stress-relief to reduce residual stress where required.

- Roller leveling and light cold-rolling for plate flatness.

- Inspection: dimensional check, hole position tolerance (CMM or optical), and surface finish inspection.

- Material traceability: mill certificates (EN/ASTM) available on request.

Typical materials and finishes

For heavy-duty service choose material for strength and wear resistance:

- Carbon steel (hot-rolled, cold-rolled) for general structural use.

- High-manganese steel for impact and abrasion resistance in crushers and screens.

- Stainless grades (304/316) for corrosion resistance and hygiene-critical settings.

- Surface finishes: mill, galvanize, powder coat, zinc/flame spray for wear protection.

RFQ checklist — what to include when requesting quotes

Use this RFQ checklist to speed accurate quotations and reduce back-and-forth. Include the following items in your enquiry (tick list):

- Material grade and any mill certificate requirement.

- Nominal thickness (mm) and acceptable tolerance.

- Plate width and length or sheet size required.

- Hole shape, size, pitch, and pattern (inline or staggered).

- Required open area percentage or maximum flow / pressure-drop spec.

- Quantity and delivery cadence (one-off, batch, repeated orders).

- Secondary operations required: trimming, welding, stiffeners, edge treatment.

- Surface finish and coating requirements.

- Expected operating environment (abrasion, corrosion, temperature).

- Target lead time and shipping terms.

When you submit an RFQ including the items above you reduce technical questions and get a more accurate price and lead time. For a factory source and detailed product options, request a quote referencing our thick-gauge perforated plate product page.

Closing / next steps

This capability overview is intended to help engineers, buyers and contractors specify heavy-duty perforated plates with clarity. Use the RFQ checklist above to prepare a clear package for quotations and supplier comparison. If you need sample drawings, material certificates or reference load-data for heavy-gauge patterns, include those files in your RFQ to accelerate technical evaluation.