Perforated safety grating plates are an efficient, long-lasting solution for industrial stair treads, platforms, ramps and walkways where slip resistance, drainage and load-bearing performance are required. Engineered for heavy duty use, these plates combine anti-slip surface texture, precise pattern punching and robust base materials to meet demanding site conditions and compliance requirements.

Why Choose Perforated Safety Grating

Perforated safety grating offers several practical advantages over alternative open-mesh or solid tread options. Its primary benefits include enhanced slip resistance, effective drainage and debris clearance, predictable structural performance, and easy customization for hole pattern, thickness and edge treatment. These features make it particularly suitable for manufacturing plants, oil & gas platforms, chemical works, and heavy engineering sites.

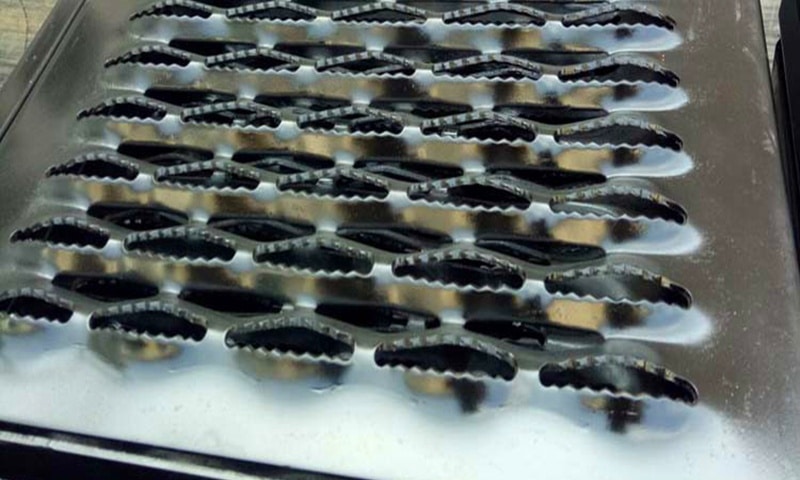

Perforated Safety Grating

Engineered perforated safety grating plate for industrial access systems.

Designed to provide slip resistance, drainage and structural strength in demanding environments such as manufacturing plants, utilities and processing facilities.

Commonly specified for:

- Stair treads and step assemblies

- Elevated walkways and access platforms

- Industrial ramps and service catwalks

Available in multiple metals and custom-fabricated to project requirements.

You can click on the product image to view the specific producible parameters or place an order.

Materials & Finishes

Carbon Steel & Galvanized Steel

Carbon steel is commonly used for heavy duty applications due to its high tensile strength and cost efficiency. When corrosion protection is required, hot-dip galvanized finishing extends service life in outdoor and industrial environments while maintaining the plate’s load-bearing capacity.

Stainless Steel

Stainless steel grades (e.g., 304, 316) are chosen where corrosion resistance, chemical exposure resistance, or hygiene considerations are priorities. Stainless perforated safety grating preserves slip characteristics and structural integrity with minimal maintenance in corrosive atmospheres.

Aluminum

Aluminum offers a lightweight alternative for situations where reduced dead load is important. While lighter, aluminum perforated plates can still provide adequate anti-slip performance when specified at appropriate thickness and punch pattern.

Typical Hole Patterns & Performance Considerations

Hole shape and spacing directly influence grip, drainage and structural stiffness. Common patterns include round punches, elliptical (fish-eye) and elongated slots. For heavy duty platforms, choose thicker gauges and smaller open-area ratios to maximize load distribution; for drainage-priority areas, larger or elongated perforations may be preferable. Proper selection balances slip resistance with load performance and maintenance needs.

Applications in Industry

Perforated safety grating is widely used for:

- Industrial stair treads and nosing

- Access platforms and service decks

- Walkways in manufacturing and processing plants

- Ramps and maintenance catwalks

For project planners seeking a ready reference, our core product page for perforated safety grating provides specifications and options (perforated safety grating ). This product page includes material choices, thickness ranges and hole patterns tailored for industrial projects.

Design, Customization & Compliance

Design considerations should include live and dead load requirements, supporting structure spacing, expected foot traffic type (boots, heels, footwear with debris), and environmental exposure. We recommend specifying:

- Gauge (thickness) based on span and load

- Punch pattern to balance grip and drainage

- Edge treatments such as folded or chamfered edges for safety

- Finish (galvanized, passivated stainless) for corrosion protection

Where applicable, confirm compliance with local building codes and workplace safety standards related to stair nosing and walkway slip resistance.

Installation & Maintenance

Installation is straightforward: plates can be mechanically fastened to stringers or welded where appropriate. Regular inspection should focus on fasteners, surface wear and corrosion. Cleaning to remove oils and embedded debris preserves anti-slip performance. For high-wear zones, consider sacrificial overlays or specifying a higher-thickness grade.

How to Specify for Procurement

When creating a purchase specification, include:

- Material grade (e.g., carbon steel S235, stainless 316)

- Plate thickness and overall dimensions

- Punch pattern and open area percentage

- Finish (hot-dip galvanized, mill finish, passivated)

- Edge details and any pre-drilled fixing holes

Conclusion

For industrial applications that demand slip resistance, drainage, and robust structural performance, heavy duty perforated safety grating is a practical, cost-effective choice. Proper material selection, punch pattern design and maintenance will deliver decades of reliable service for stair treads, platforms and walkways.