Modern architectural façades increasingly rely on metal elements that combine functional performance with refined visual effects. Among the many perforated patterns used in building envelopes, hexagonal perforated metal panels have become especially valued for their proportional geometry, light management, and flexible design options. Their ability to offer controlled transparency while creating a dynamic appearance makes them a strong choice for contemporary exterior systems.

Why Hexagonal Perforations Support Architectural Transparency

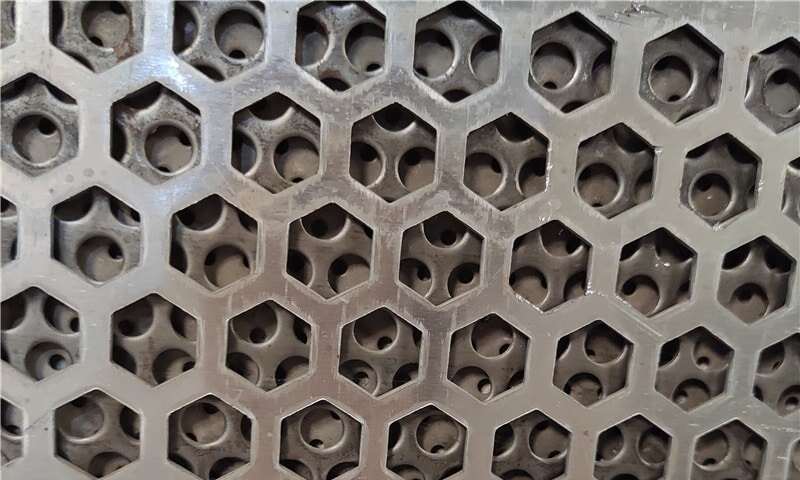

The hexagonal pattern is unique because it creates a balanced distribution of open and solid areas. Unlike round or square openings, hexagonal shapes naturally interlock, forming an even, honeycomb-like structure. This leads to smoother visual transitions and more uniform transparency.

Consistent Light Flow

The uniform distribution of openings allows daylight to pass through in a stable, diffused manner. This is especially useful in:

- Shading systems

- Semi-transparent building skins

- Ventilated façades

The visual effect is soft rather than harsh, helping architects balance natural light without exposing interiors completely.

Controlled Ventilation

Hexagonal perforations also support consistent airflow. For façade systems used in warm regions or buildings requiring natural ventilation, this pattern helps maintain comfort without sacrificing appearance.

Commonly Used Materials

When specifying façade panels, architects often compare options such as:

- Carbon steel perforated sheets

- Galvanized perforated metal

- Aluminum perforated sheets

- Stainless steel perforated panels

Each material can be produced with different thicknesses, opening sizes, and open-area ratios to meet engineering and architectural needs.

Customization Options

Hexagonal perforated metal panels can be tailored for:

- Panel width and length

- Opening size and pitch

- Material thickness

- Surface treatments

- Percentage of open area

This level of flexibility supports both functional façades and decorative architectural screens.

Enhancing Visual Identity Through Façade Patterns

Hexagonal perforations naturally create a geometric rhythm. When the sun moves across the façade, the surface produces changing shadow patterns that shift throughout the day. This gives buildings a more vivid presence without requiring complex 3D shapes or heavy ornamentation.

Combining with Other Perforation Designs

In some projects, designers combine hexagonal perforations with other patterns to express brand identity or emphasize building zones. Related options include:

- Round hole perforated metal

- Square perforated metal

- Slotted perforated sheets

- Micro-perforated metal panels

These pattern variations allow the façade to incorporate textures with different levels of transparency while keeping the overall visual narrative consistent.

Structural Performance and Practical Considerations

Although hexagonal perforated metal panels are designed primarily for visual and shading purposes, they also offer steady mechanical performance due to the distribution of material around the openings.

Lightweight Yet Durable

Depending on the selected material, hexagonal perforated panels can achieve a good balance between weight reduction and structural stability. This helps reduce installation load while maintaining sufficient rigidity for façade frameworks.

Compatible With Multiple Installation Systems

These panels can be used with:

- Standard aluminum framing

- Cassette-type façade modules

- Suspended cladding structures

- Secondary steel frameworks

Their versatility simplifies integration into both new constructions and renovation projects.

Applications Across Architectural Projects

Hexagonal perforated panels appear in a wide range of building types due to their blended functional and visual strengths:

- Public buildings with expressive façades

- Commercial and retail complexes

- Parking structures requiring ventilation

- Transportation hubs and stations

- Screening around mechanical or service areas

- Exterior sunshade systems

Their consistent pattern also makes them suitable for interior elements, such as feature walls or ceiling systems.

Why Hexagonal Perforated Panels Support Modern Façade Trends

Architects often seek materials that reflect modernity, efficiency, and clean geometry. The hexagonal pattern aligns well with these goals:

- It expresses a clear geometric identity

- It supports environmental performance through light and airflow control

- It adapts easily to custom requirements

- It enhances the visual texture of building surfaces

This combination explains why the pattern continues to gain popularity in global façade design.

Conclusion

Hexagonal perforated metal panels bring together transparency, structural simplicity, and contemporary aesthetics. Their balanced visual rhythm and consistent open-area distribution make them one of the most adaptable choices for modern façade systems. With the ability to customize materials, thicknesses, opening ratios, and surface finishes, these panels provide architects and project planners with both creative freedom and practical performance.