Introduction

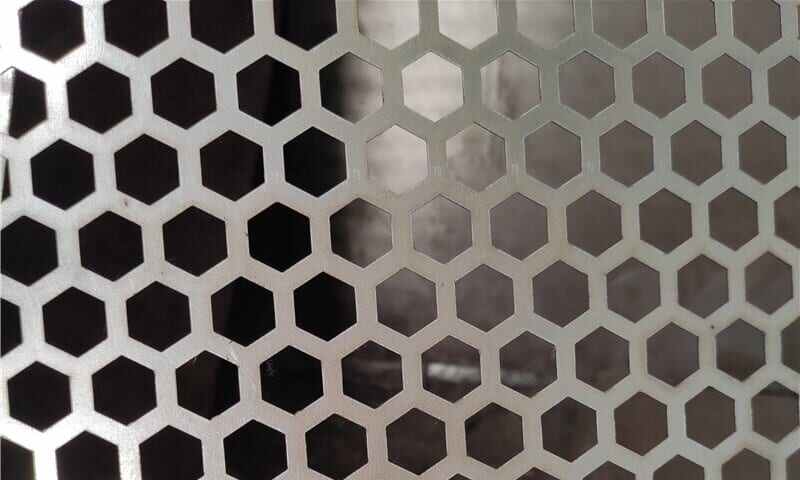

In modern architectural design, the integration of functional elements with aesthetic appeal has become more crucial than ever. Among these elements, Hexagonal Perforated Metal Sheets stand out for their versatility and effectiveness. Widely used in building facades, these sheets offer not only structural integrity but also significant benefits in terms of ventilation and sunshading. This article explores how these perforated metal sheets play a pivotal role in enhancing the functionality of building exteriors while contributing to energy efficiency and visual appeal.

Ventilation Benefits of Hexagonal Perforated Metal Sheets

The primary function of Hexagonal Perforated Metal Sheets in building facades is to provide efficient airflow. Their unique hexagonal hole pattern creates an optimal balance between airflow and structural strength, making them ideal for environments that require natural ventilation. This pattern allows air to pass freely while still maintaining a solid barrier against external elements like dust, rain, and noise.

For buildings in warmer climates or areas with high humidity, perforated metal sheets help regulate internal temperatures by promoting air circulation. This natural ventilation reduces the reliance on air conditioning systems, leading to significant energy savings and a more sustainable approach to building design.

Moreover, the hexagonal perforation ensures that the air can move in multiple directions, further enhancing the efficiency of the building’s ventilation system. The openness and size of the holes can be customized to meet the specific airflow requirements of a given project, making them an adaptable solution for a variety of building types, from office towers to industrial complexes.

Sunshading Effectiveness of Hexagonal Perforated Metal Sheets

Apart from ventilation, Hexagonal Perforated Metal Sheets also serve an important role in sunshading. The perforation pattern significantly reduces the amount of direct sunlight entering the building without completely blocking out light. This controlled light filtration helps maintain a comfortable indoor environment, minimizing glare and heat buildup inside the building.

In regions where high solar exposure can lead to overheating and increased cooling costs, these perforated sheets can act as an effective passive sunshading solution. By adjusting the size and arrangement of the holes, it’s possible to optimize the shading effect while still allowing for daylight penetration, thus reducing the need for artificial lighting.

Sunshading Effectiveness of Hexagonal Perforated Metal Sheets

Apart from ventilation, Hexagonal Perforated Metal Sheets also serve an important role in sunshading. The perforation pattern significantly reduces the amount of direct sunlight entering the building without completely blocking out light. This controlled light filtration helps maintain a comfortable indoor environment, minimizing glare and heat buildup inside the building.

In regions where high solar exposure can lead to overheating and increased cooling costs, these perforated sheets can act as an effective passive sunshading solution. By adjusting the size and arrangement of the holes, it’s possible to optimize the shading effect while still allowing for daylight penetration, thus reducing the need for artificial lighting.

Additionally, hexagonal perforated metal sheets can be used in combination with other building materials to create dynamic and aesthetically pleasing designs. Whether used as standalone sunshades or integrated into the facade, they offer both functional and visual benefits that enhance the overall building architecture.

Real-World Applications of Hexagonal Perforated Metal Sheets

The versatility of Hexagonal Perforated Metal Sheets makes them suitable for a wide range of applications. In urban environments, these sheets are commonly seen in commercial and residential buildings where a balance between light, air, and privacy is needed.

For example, office buildings in densely populated areas use perforated metal sheets to improve privacy while still allowing airflow and light to penetrate. In industrial settings, these sheets provide the perfect solution for large-scale ventilation systems while protecting against environmental elements.

ALT=“Industrial building with hexagonal perforated metal sheets used for ventilation and sunshading”

Additionally, their use is not limited to functional purposes. Architects and designers frequently incorporate perforated metal sheets into building facades for their ability to add a modern, sleek look. The subtle yet impactful design enhances the building’s exterior without overwhelming it, creating a contemporary and professional appearance.

Conclusion

In conclusion, Hexagonal Perforated Metal Sheets provide an effective and multifunctional solution for building facades, offering both ventilation and sunshading benefits. Their adaptability, durability, and aesthetic appeal make them an ideal choice for architects, engineers, and designers seeking to improve building performance while maintaining a modern, attractive exterior.

Whether you are looking to enhance the energy efficiency of your building, reduce cooling costs, or add a unique design element to your facade, hexagonal perforated metal sheets are an excellent choice. Contact us today to discuss how our customizable products can meet your specific needs.