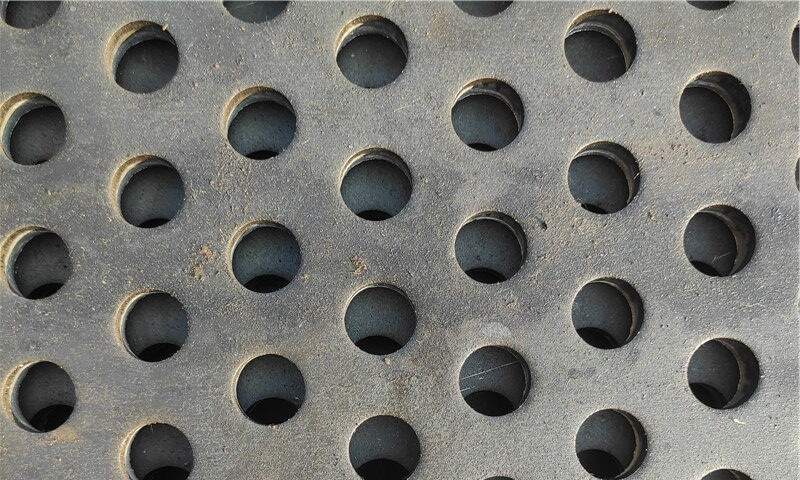

In the field of industrial filtration, protection, and mechanical screening, perforated metal sheets play a vital role due to their combination of strength, durability, and versatility. Among the various materials available, high manganese steel perforated metal plate and carbon steel perforated metal sheets stand out as two popular options for wear-resistant environments.

This article analyzes the characteristics, performance, and applications of both materials, helping you determine which type best suits your specific project needs.

1. Understanding the Materials

High Manganese Steel Perforated Metal Plate

High manganese steel, often known as Hadfield steel, contains 11–14% manganese and exhibits excellent work hardening properties. When subjected to impact or abrasion, its surface becomes extremely hard while maintaining toughness underneath.

This makes the high manganese steel perforated metal plate ideal for industries such as mining, construction, and heavy machinery where impact and wear are severe.

Carbon Steel Perforated Metal Sheet

In contrast, carbon steel perforated metal sheets offer a balance between cost-effectiveness and strength. They are easier to process, weld, and form compared with high manganese steel.

Although less wear-resistant, carbon steel performs well in general mechanical protection, ventilation, and decorative applications, especially when coated or galvanized for corrosion resistance.

Key Differences Between High Manganese and Carbon Steel Perforated Metal Sheets

| Feature | High Manganese Steel | Carbon Steel |

| Hardness (after impact) | Increases significantly due to work hardening | Stable but lower |

| Toughness | Excellent even at high hardness | Moderate |

| Machinability | More difficult to cut and form | Easy to process |

| Cost | Higher | More economical |

| Corrosion Resistance | Moderate, can be improved by coating | Requires surface protection |

| Applications | Mining screens, crushers, impact liners | Ventilation panels, facades, machinery guards |

3. Applications in Wear-Resistant Fields

In wear-resistant engineering, the choice between these two materials largely depends on the severity of impact and abrasion.

- High manganese steel perforated metal plates are widely used in crusher screens, vibrating machines, and heavy-duty filters. Their self-hardening property ensures long service life in continuous impact environments.

- Carbon steel perforated metal sheets, on the other hand, serve best in medium-load systems, protective barriers, or architectural facades where wear is less severe but formability and cost efficiency matter more.

For enhanced corrosion resistance, many users also turn to galvanized perforated metal sheets or stainless steel perforated metal sheets, which combine durability with rust protection.

4. Customization and Design Flexibility

At Anping Senchi Metal Wire Mesh Co., Ltd., both high manganese and carbon steel perforated metal sheets can be customized in various:

- Thicknesses

- Hole patterns (round, square, hexagonal, slotted, and more)

- Open area ratios

- Sheet sizes and surface finishes

Customers can select from specialized designs like round hole perforated metal sheets, slot hole perforated metal sheets, and even Perforated Safety Grating for anti-slip and load-bearing applications.

This flexibility allows our clients to meet both functional and aesthetic requirements in industrial and architectural projects.

5. Choosing the Right Material

When selecting between high manganese and carbon steel perforated metal sheets, consider these key factors:

- Operating environment (high impact vs. general use)

- Required service life

- Budget and maintenance costs

- Corrosion resistance needs

For extremely abrasive environments, high manganese steel is the preferred option. For projects that prioritize cost-effectiveness, machinability, and moderate wear resistance, carbon steel remains an excellent choice.

Conclusion

Both high manganese steel perforated metal plates and carbon steel perforated metal sheets offer unique benefits depending on the application. Understanding their differences helps you make informed decisions for wear-resistant and structural projects.

Contact info@perfsheet.com today for customized perforated metal sheet solutions tailored to your specific industrial needs.