In modern architectural and industrial design, acoustic performance has become just as important as structural strength and visual appeal. Among various materials used for sound-absorbing walls, honeycomb perforated metal panels stand out for their unique combination of durability, acoustic efficiency, and aesthetic flexibility. These panels not only improve noise reduction but also add a refined, modern texture to interior and exterior wall systems.

What Makes the Honeycomb Structure Unique

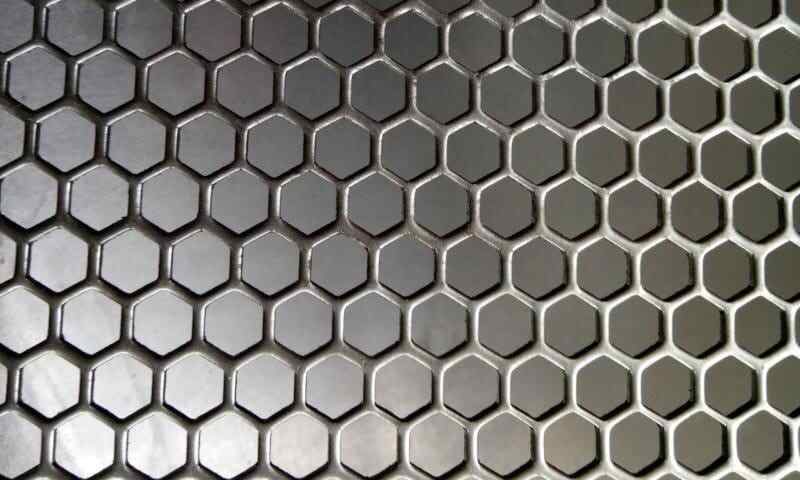

The honeycomb pattern, known for its geometric precision, distributes stress evenly and provides exceptional strength-to-weight ratio. This structure enables the perforated metal sheet to maintain rigidity even with a high open area percentage.

Compared with round or square perforations, the hexagonal hole pattern maximizes the surface area available for air and sound wave passage, which improves acoustic absorption. When sound waves pass through these perforations, they enter the cavity behind the panel—where noise energy is effectively dissipated through friction and resonance.

Acoustic Performance and Noise Control

Honeycomb perforated panels are often used in environments where controlling noise and echo is crucial—such as theaters, auditoriums, factories, and public transportation terminals. The perforations can be tailored in terms of hole diameter, pitch, and open area ratio, allowing precise tuning of the panel’s sound absorption performance.

In some projects, these panels are combined with sound-absorbing materials like mineral wool or fiberglass to enhance performance even further. The result is a wall system that not only absorbs unwanted noise but also reflects balanced frequencies to create a comfortable acoustic environment.

Material Flexibility and Customization

One of the greatest advantages of choosing a honeycomb perforated metal sheet is the wide range of materials and finishes available. Depending on the project’s requirements, panels can be made from:

- Aluminum perforated metal sheet – lightweight and corrosion-resistant

- Stainless steel perforated metal sheet – ideal for outdoor or humid environments

- Galvanized perforated metal sheet – cost-effective and durable

- Carbon steel perforated metal sheet – excellent for high-strength applications

Each material can be produced in different thicknesses, hole diameters, and open area ratios, ensuring perfect fit and acoustic performance. The flexibility of customization—from micro perforations to large hexagonal holes—makes it easy to match both functional and decorative needs.

Structural Strength and Aesthetic Appeal

Beyond acoustics, the honeycomb pattern brings visual sophistication to architectural projects. Its symmetrical, geometric appearance creates a modern and technical impression, making it suitable for both interior wall cladding and facade decoration.

From a structural standpoint, the interlocking geometry of the honeycomb design provides outstanding load-bearing performance while maintaining low weight. This makes installation faster and safer compared to heavier, non-perforated materials.

Environmental and Economic Benefits

Using honeycomb perforated metal panels in acoustic walls also aligns with sustainability goals. The materials are fully recyclable and require minimal maintenance, reducing long-term costs. Their ability to improve indoor sound quality contributes to healthier and more comfortable environments, which is especially valued in commercial and public spaces.

Additionally, since these panels can be produced in custom sizes and shapes, waste is minimized during production and installation—a key factor in green building certifications.

Applications Across Industries

Because of their structural strength, acoustic efficiency, and decorative potential, honeycomb perforated metal panels have been adopted in a number of sectors where sound control and design matter.

In architectural acoustics, they are commonly used for sound-absorbing walls and ceilings in theaters, lecture halls, and commercial interiors—often paired with an internal absorber or a micro-perforated liner to fine-tune frequency response.

In industrial settings, these panels serve well as machine enclosures and localized noise barriers, offering a rigid yet lightweight solution that helps reduce machinery noise levels without heavy construction. For projects that require both airflow and acoustic control, designers frequently combine honeycomb panels with micro perforated sheets to achieve targeted absorption across specific frequencies.

Beyond functional uses, honeycomb perforated panels also provide a distinctive façade treatment for modern buildings, where texture and shadow play add visual interest while still meeting acoustic goals.

Conclusion

In summary, the honeycomb perforated metal panel represents a perfect balance between engineering performance and architectural beauty. Its unique hexagonal structure enhances sound absorption, structural integrity, and design flexibility—making it an excellent choice for modern acoustic wall systems.

As a professional manufacturer specializing in customized perforated metal sheets, we can provide tailor-made honeycomb designs that meet your exact acoustic, structural, and aesthetic requirements. Whether you need a single prototype or mass production, we are ready to deliver quality solutions that perform and impress.

📧 Contact us: info@perfsheet.com