Why Honeycomb Perforated Panels Are Gaining Popularity in Modern Ceilings

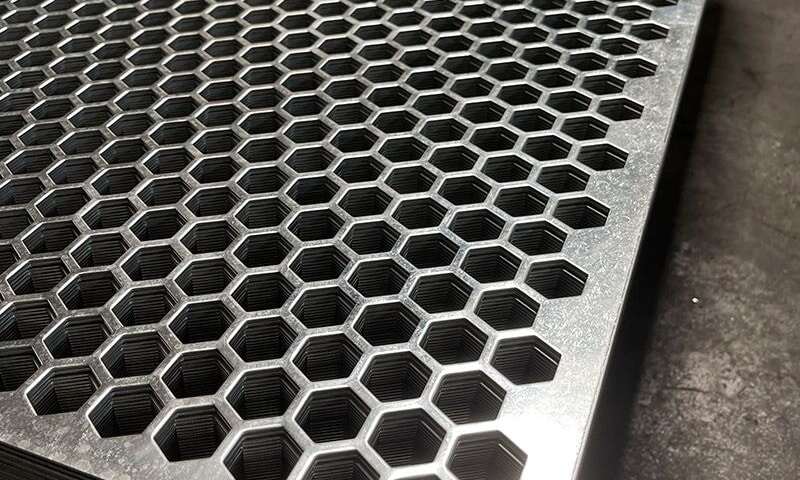

Honeycomb Perforated Panels have become a preferred material in contemporary ceiling design thanks to their balanced mix of visual appeal and practical performance. The signature hexagonal pattern brings a geometric elegance that is subtle yet distinctive, making it suitable for offices, lobbies, retail spaces, and hospitality environments.

Designers value how seamlessly these panels integrate with modern architectural styles—from minimal industrial interiors to warm, natural palettes. At the same time, the panels provide functional advantages such as sound absorption, airflow control, and the ability to conceal ceiling services without adding weight or requiring extensive maintenance.

Key Advantages of Honeycomb Perforated Panels for Ceiling Applications

Modern Aesthetic with Depth and Character

The hexagonal perforation pattern adds unique dimensionality to a ceiling. As light moves across the surface, it creates soft shadows and elegant highlights. By adjusting hole size, spacing, and finish, designers can control the intensity of the visual effect—from subtle sophistication to bold statement zones.

Enhanced Acoustic Performance

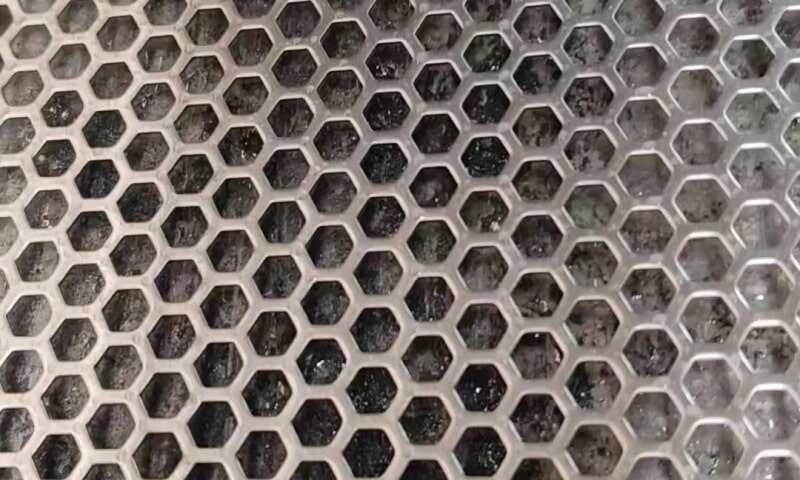

When paired with acoustic infill or backing materials, Honeycomb Perforated Panels contribute significantly to reducing echo and improving speech clarity. This makes them ideal for open-plan offices, restaurants, commercial centers, and educational facilities.

Improved Ventilation and Service Integration

The perforations allow airflow while keeping HVAC ducts hidden, making these panels particularly effective in areas requiring clean visual lines. By customizing open-area percentage, projects can balance ventilation and privacy with ease.

Durability and Lightweight Construction

Materials such as aluminum and stainless steel ensure long-term structural stability with minimal upkeep. Lightweight panel options streamline installation and reduce labor costs, while finish choices support both performance and sustainability objectives.

Customization Options Designers and Contractors Appreciate Most

One reason Honeycomb Perforated Panels are increasingly specified is the wide range of customization, including:

- Material choices: aluminum, stainless steel, galvanized steel, copper, or brass

- Thickness options: from thin architectural gauges to reinforced structural gauges

- Hole sizes & open areas: fine honeycomb perforations for acoustics; larger openings for ventilation

- Panel dimensions: custom sizes to minimize seams and fit unique ceiling grids

- Finishes: anodized, powder-coated, brushed metal, matte, satin, or gloss

- Additional features: acoustic backing, integrated lighting channels, or access panels

These options allow architects to tailor ceilings to meet performance standards and match the overall design intent.

Where Honeycomb Perforated Panels Are Used Most Often

Common applications include:

- Offices and co-working spaces

- Hotel lobbies and hospitality venues

- Retail stores and brand showrooms

- Restaurants and modern cafés

- Transportation centers like airports and metro stations

- Educational and cultural facilities

These ceiling systems help unify the architectural aesthetic while providing important technical benefits like acoustics and airflow.

Installation Tips for Smooth Project Execution

- Finalize specs early: confirm panel sizes, perforation pattern, and finish to avoid field modifications.

- Request a mock-up: verify pattern visibility, color consistency, and acoustic backing before mass production.

- Check tolerances: ensure edges, suspension systems, and expansion gaps are properly defined.

- Plan acoustic performance before ordering: selecting the backing during production avoids costly rework.

- Prepare maintenance guidelines: proper cleaning ensures long-term appearance and performance.

Cost & Value Considerations

While cost varies based on material, finish, and customization, Honeycomb Perforated Panels can reduce overall project expenses by:

- Limiting secondary finishes

- Reducing exposed mechanical clutter

- Lowering installation labor

- Enhancing acoustic performance without extra treatment

- Offering long-lasting durability and low maintenance requirements

The ability to produce both small prototype quantities and large-volume orders adds flexibility for all types of construction projects.

Future Design Trends Involving Honeycomb Perforated Panels

Emerging ceiling trends highlight several creative applications:

- Backlit honeycomb ceiling zones with LED integration

- Gradient perforation patterns shifting from dense to open across large spaces

- Mixed-material ceilings combining metal panels with wood or textile elements

- Eco-friendly finishes and recycled metals for sustainable design initiatives

These trends suggest that Honeycomb Perforated Panels will remain a defining feature of modern interior architecture.

Quick Specification Checklist

- Panel material & finish

- Panel size & edge profile

- Hole size, spacing & open area

- Acoustic backing requirements

- Fire rating compliance

- Installation method & access points

- Quantity: prototype vs. mass production

Honeycomb Perforated Panels combine aesthetics, flexibility, and performance, making them one of the most versatile options for today’s ceiling projects. If you need samples, drawings, or a quotation tailored to your specifications, feel free to reach out.

Contact: info@perfsheet.com