Micro-perforated metal panels have become a trusted solution in architectural acoustics thanks to their ability to achieve powerful sound absorption without foam, fabric, or traditional porous materials. Their performance is closely tied to how they interact with sound at different frequencies. Understanding this frequency response is essential for choosing the right panel configuration for any environment—from industrial halls to home studios.

To help clarify the principles, this article explains the fundamentals in a straightforward and beginner-friendly way while also highlighting how customizable micro-perforated panels can achieve specific acoustic goals.

What Makes Micro-Perforated Panels Unique?

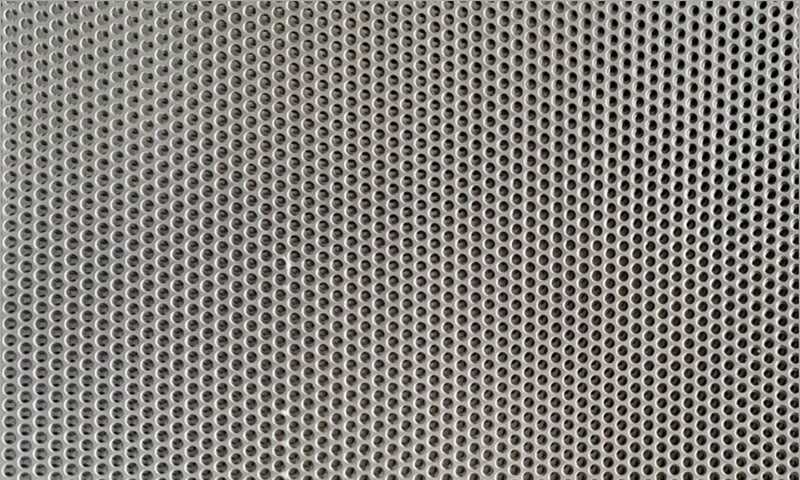

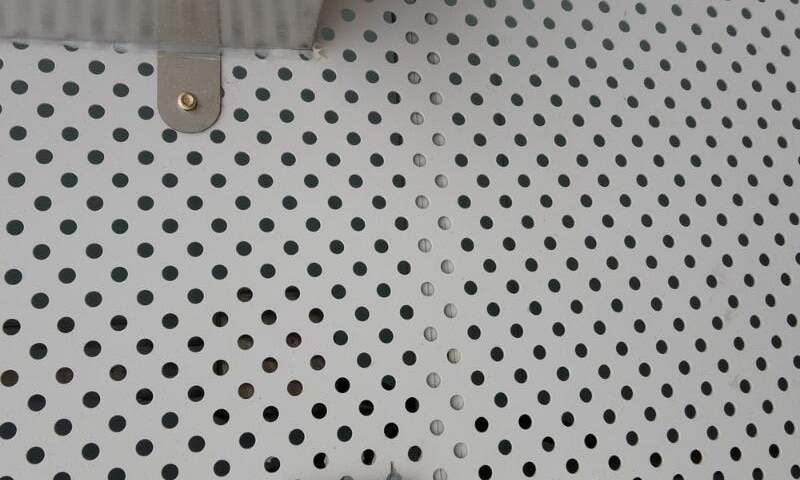

Unlike typical perforated sheets, micro-perforated acoustic panels feature extremely small holes—usually 0.8–3.0 mm in diameter—and a carefully calculated open area. These tiny openings create a specific acoustic resistance that interacts with incoming sound waves.

Three major features make them especially effective:

- Small hole diameters that create resistance to airflow

- Controlled perforation ratio that influences how much sound energy enters the cavity

- Precisely tuned panel thickness and cavity depth that determine the working frequency range

This combination allows them to absorb sound without the need for fiberglass or mineral wool.

How Micro-Perforations Absorb Sound

The sound absorption mechanism is based on Helmholtz resonator principles, but simplified:

- Sound waves enter the tiny holes.

- Air inside each hole oscillates, generating friction against the hole walls.

- The friction converts acoustic energy into heat, which significantly reduces reverberation.

- A backing air cavity magnifies the absorption at certain frequencies through resonance.

The result is a system that absorbs sound selectively rather than uniformly. This is why tuning the frequency response is a key part of acoustic design.

Why Frequency Response Matters in Acoustics

Every room has problem frequencies—those that create echoes, flutter reflections, or booming effects. Micro-perforated panels are ideal because they can be customized to target those trouble zones.

The frequency response is shaped by five primary factors:

1. Hole Diameter (e.g., 0.8–3.0 mm)

Smaller holes increase acoustic resistance, shifting absorption toward higher frequencies.

Larger micro-holes (closer to 3.0 mm) lower the resonant frequency.

2. Panel Thickness

A thicker plate slightly increases mass, modifying the interaction between sound waves and the perforations.

3. Perforation Ratio

A typical range is 0.5%–3%.

Lower ratios improve absorption at specific narrow frequencies.

Higher ratios allow broader frequency absorption.

4. Cavity Depth Behind the Panel

This has the strongest effect on tuning.

- Shallow air cavity → higher absorption frequency

- Deep air cavity → lower absorption frequency

For example:

A 50 mm cavity may absorb mids;

A 100 mm cavity can bring the resonance into the low-frequency range.

5. Material Type

Although metal is most common due to durability, different materials vary slightly in rigidity and surface behavior, subtly affecting absorption peaks.

Real-World Example of Frequency Response Tuning

Consider a common setup:

- Hole diameter: 0.5 mm

- Thickness: 1 mm metal sheet

- Perforation ratio: 1%

- Cavity depth: 80 mm

This configuration might create a strong absorption peak around mid-range frequencies. If the goal is to treat lower frequencies, the cavity could be increased to 120 mm or the perforation ratio reduced slightly.

This flexibility makes micro-perforated panels ideal for:

- Office acoustic treatments

- Public spaces requiring fire-safe materials

- Concert halls and auditoriums

- Machinery noise control

- Architectural features that demand both durability and acoustic performance

Because the panels work without soft materials, they are suitable for clean-room environments, humid areas, and locations requiring high hygiene standards.

How Customization Maximizes Acoustic Results

One of the greatest strengths of micro-perforated designs is the ability to tailor every parameter:

- Custom hole patterns

- Non-standard panel sizes

- Unique geometries

- Precise open-area percentages

- Special metals such as aluminum, stainless steel, or galvanized steel

- One-off prototypes or large-scale production

With these options, it becomes possible to tune the exact frequency range and absorption level needed for any project.

Micro-perforated metal panels provide a powerful, flexible, and clean acoustic solution. By adjusting hole diameter, perforation ratio, plate thickness, and cavity depth, their frequency response can be precisely matched to the needs of any acoustic environment.

If you are planning a project and need customized micro-perforated acoustic panels, you can get professional guidance and tailored solutions.

Feel free to contact us at info@perfsheet.com for inquiries, quotations, or technical support.