Micro-perforated filter plates play a crucial role across many industries—from precision filtration and separation to acoustic control and architectural applications. Regardless of where they are used, their performance relies heavily on two things: the accuracy of the perforations and the durability of the material operating within its specific environment.

When a filter plate fails—whether through corrosion, wear, or material degradation—the entire system can suffer. Unexpected downtime, product contamination, or reduced filtration efficiency can significantly increase operational costs. That’s why selecting the right material is not simply a technical step but an essential long-term investment.

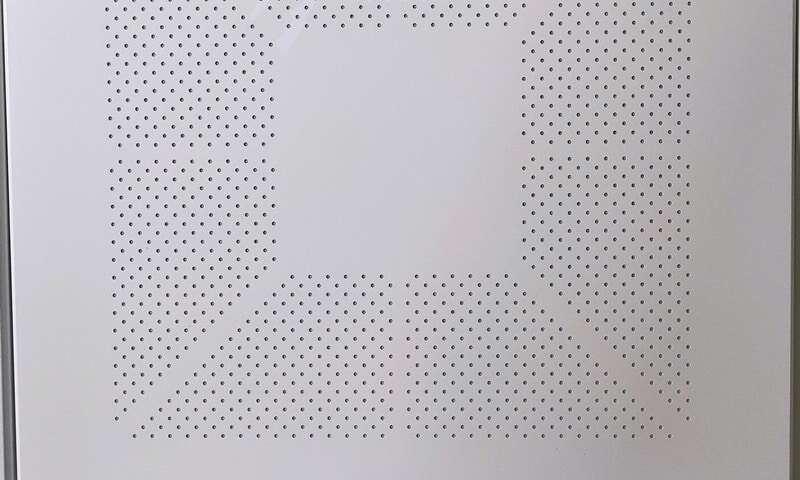

Micro Perforated Metal Sheets

Micro perforated metal sheets are designed with tiny, precise holes that support sound absorption and airflow/filtration in compact designs. Perfect for applications requiring precision and fine perforations.

Why Corrosion Resistance Matters

Every micro-perforated filter plate is continually exposed to the medium it is filtering—whether that’s hot gases, chemical solvents, abrasive slurries, or corrosive saltwater. The selected material must provide adequate mechanical strength, but more importantly, it must withstand the chemical and environmental factors it will face.

Ignoring corrosion resistance can lead to:

- Shortened service life caused by rapid material degradation

- Product contamination from flaking or corroded metal

- Reduced filtering accuracy due to damaged micro-holes

- Higher maintenance and replacement costs

This makes material selection one of the most critical decisions in the design of a micro-perforated filter system.

Comparison of Common Micro-Perforated Filter Plate Materials

1. Stainless Steel (Industry Standard)

Stainless steel is the most widely used material thanks to its balance of strength, cost efficiency, and corrosion resistance.

Common Grades and Benefits

| Grade | Typical Applications | Corrosion Advantages | Notes |

|---|---|---|---|

| 304 | Water/air filtration, food processing, general industry | Good resistance to oxidation and mild chemicals | Ideal for non-chloride environments |

| 316 / 316L | Marine uses, chemical processing, pharmaceuticals | Superior pitting and crevice corrosion resistance, excellent chloride resistance | Recommended for seawater or strong chemical cleaning |

Why choose it?

Reliable, durable, and versatile with excellent mechanical properties.

2. Carbon Steel (Cost-Effective Choice)

Carbon steel offers high strength at a low cost, but it has inherently weak corrosion resistance.

To make it viable for real applications, it must be protected with coatings:

- Hot-dip galvanizing

- Powder coating

- PVC coating

These treatments improve performance, but durability depends entirely on coating integrity.

Best for: economically sensitive projects, dry environments, or low-corrosion industrial systems.

3. Aluminum (Lightweight and Versatile)

Aluminum is ideal when weight reduction is a priority. It naturally forms a protective oxide layer that resists atmospheric corrosion.

Advantages:

- Excellent strength-to-weight ratio

- Good resistance to weather and mild chemicals

- Easy to form and perforate

Limitations:

- Not suitable for strong acids or alkaline environments

- Can suffer pitting under certain chemical exposures

Best for: HVAC systems, architectural panels, aerospace components, ventilation systems.

High-Performance Materials for Extreme Conditions

4. Titanium

Titanium is one of the most corrosion-resistant metals available for micro-perforated filter plates.

Key Advantages:

- Exceptional resistance to seawater, chlorides, and acidic/alkaline media

- High strength-to-weight ratio

- Excellent high-temperature performance

Best for: petrochemical processing, offshore platforms, aerospace filtration, highly corrosive industrial systems.

5. Nickel-Based Alloys (Inconel, Monel, Hastelloy)

These specialty alloys are engineered for extreme corrosion and temperature conditions.

Performance Characteristics:

- Outstanding stability in strong acids and alkalis

- Highly resistant to oxidation at elevated temperatures

- Excellent mechanical strength under thermal cycling

Typical Uses:

- Chemical reactors

- Refinery equipment

- High-temperature gas filtration

- Aggressive chemical environments

Customization: The Key to Corrosion Control and Optimal Performance

Using generic perforated sheets often leads to two problems:

- Over-engineering → paying for unnecessary properties

- Under-engineering → premature failure

The most effective solution is full customization based on the actual working environment.

A professional manufacturer can tailor the following:

1. Material Grade

Select specific alloys (304, 316L, titanium, nickel alloys, etc.) to match corrosion factors without unnecessary cost.

2. Thickness and Mechanical Strength

Choose the exact thickness needed to support operational loads while allowing precise micro-perforation.

3. Hole Size and Pattern

Custom micro-holes—from fractions of a millimeter to specialized open-area ratios—ensure accurate filtration or acoustic performance.

4. Plate Dimensions

Produce any size or shape, from a single small part to large industrial panels.

5. Surface Treatments

Apply powder coating, protective films, or specialized finishes to extend durability in harsh environments.

How to Make the Right Material Decision

Use this checklist to select the ideal micro-perforated filter plate material:

- Identify corrosive agents: chemicals, pH levels, moisture, chlorides

- Define temperature and pressure ranges

- Assess mechanical load and structural needs

- Determine required filtration accuracy

- Match material properties to working environment

By partnering with a manufacturer capable of flexible customization—from single prototypes to mass production—you ensure maximum lifespan and performance without compromise.

Ready to Build Your Custom Micro-Perforated Filter Solution?

When precision matters, generic components are not enough. Customized micro-perforated filter plates offer the exact material, thickness, hole pattern, and durability needed for optimal performance in any industrial environment.

Whether you require a single specialized part or a large production run, our flexible manufacturing capabilities are designed to support your requirements.

Contact us to discuss your project and get professional material recommendations.

📧 Email: info@perfsheet.com

We’re here to help you choose the ideal material and design for your filtration system.