Definition and purpose

What is a Perforated Safety Grating Plate?

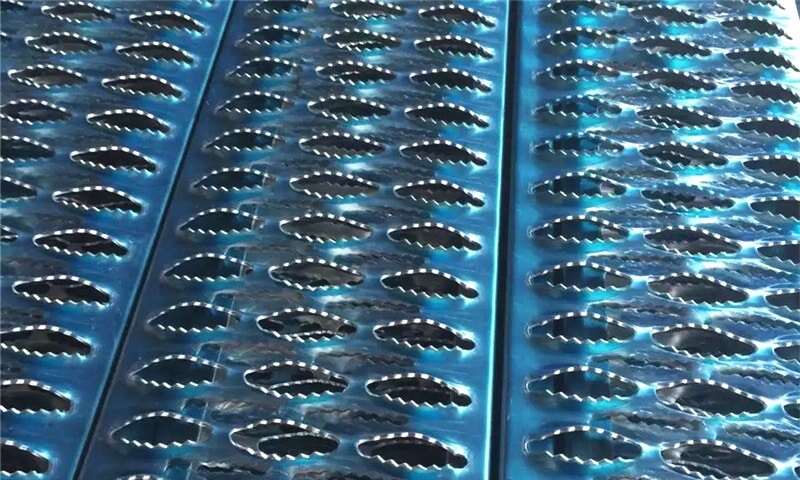

A perforated safety grating plate is a metal plate manufactured with a pattern of holes or slots that provides traction, drainage, and a defined open area while retaining structural strength for pedestrian and light equipment loads. These plates are specified as stair treads, walkway panels, and platform infills where slip resistance and drainage are required.

Primary functions

- Slip resistance and traction for personnel in wet, oily, or debris-prone environments.

- Drainage and debris shedding through the perforations to reduce pooling and ice build-up.

- Load carrying across a given span when supported correctly by substructure or stringers.

- Customizability of hole pattern, thickness, and edge/nosing detail for specific applications.

Typical industrial applications

Common use cases

- Stair treads and nosings on production platforms and access stairs.

- Walkways and catwalks in manufacturing, petrochemical and food-processing facilities.

- Access platforms and mezzanines where ventilation and light transmission are desirable.

- Ramps and service corridors requiring slip control and drainage.

For stair/step applications, grating and treads are typically specified to comply with general stair dimensional and safety rules from OSHA and industry practice.

Materials and construction

Typical metals used

- Carbon steel (often the most economical for structural load).

- Hot-dip galvanized steel for corrosion resistance in outdoors or washdown environments.

- Stainless steel (304/316 grades) for corrosive or sanitary environments.

- Aluminum when weight savings are a primary concern and moderate corrosion resistance is needed.

Material selection balances budget, corrosion environment, and design life. Relevant material specifications are commonly referenced to ASTM classifications when writing purchase specs.

Manufacturing processes

Perforated plates are typically produced by die punching (punch press), rotary pin perforation, or laser cutting for specialized patterns and tight tolerances. Secondary operations include nosing formation, debur/edge finishing, and coating/galvanizing. Choose the fabrication method that matches required pattern accuracy, production volume and cost constraints.

Types and pattern options

Common hole geometries

- Round holes — simple, high open area, standard tooling.

- Slotted (elongated) holes — improved drainage and grip directionality.

- Staggered (offset) patterns — increases traction and spreads load.

- Serrated or knurled edges on hole rims — adds micro-traction for footwear.

Industry language favors describing pattern by hole type, pitch, open area %, and edge treatment.

Specialty anti-slip finishes

For aggressive slip resistance, manufacturers supply serrated punch rims, raised chequer patterns, or nosing details that interlock with footwear tread. These options are chosen when wet/oily service or steep incline ramps are present.

Structural performance and load design

Load parameters engineers use

Designers specify bearing span, panel thickness, and support spacing to meet required uniformly distributed loads (UDL) and point/line loads from equipment or concentrated foot traffic. Supply or request span/load tables from the manufacturer and validate with structural calculations for the intended support grid. Manufacturer catalogs typically supply allowable loads for standard bearing bar or plate thickness configurations.

Design considerations

- Open area percentage affects drainage but reduces net cross-section for load carrying.

- Support spacing (stringer/joist centers) must be coordinated with panel size and thickness.

- Deflection limits should be set per application (personnel comfort vs. equipment sensitivity).

- Toeboards and edge cleats may be required where small-object retention is important.

Slip resistance, testing and specification tips

How to specify traction

Request or verify coefficient of friction (COF) or dynamic slip test results (e.g., ASTM test methods used by suppliers) for the installed finish under the expected contaminant (water, oil, grease). Also specify abrasive/serrated options if personnel safety under oily conditions is critical.

Practical procurement note

When issuing a purchase order or spec sheet, include: material grade, pattern (hole type and pitch), thickness, surface finish/coating, panel size, edge/nosing detail, and support spacing reference. Ask vendors for load/span tables, sample panels, and test data for COF if slip-resistance is a safety-critical attribute.

Safety, code references and compliance

Regulatory and industry guidance

Stair and tread dimensioning and general stair safety are addressed in OSHA regulations and guidance documents (e.g., stair tread depth, riser heights and minimum clearances). For material and grading specs, refer to relevant ASTM standards and manufacturers’ product catalogs for load-rating conventions. Always cross-check local building code or project-specific standards in addition to federal guidance.

Spec-writing checklist (short)

- Project name & location

- Item description: perforated safety grating plate with hole type, pitch, and open area %

- Material & finish: e.g., ASTM A1011 carbon steel, hot-dip galvanized to ASTM A653, or stainless steel 304/316

- Panel dimensions and thickness

- Edge/nosing details and fastener type

- Acceptable load/span table or required allowable loads

- Slip-resistance requirement or COF test method

- Manufacturer quality/QA requirements and delivery lead time