In industrial environments, safety is always the top priority — especially when it comes to preventing slips and falls. Floors, walkways, and platforms often become slippery due to the presence of oil, water, or dust. This is where perforated safety grating plays an essential role. With its unique surface structure and durable materials, it offers exceptional slip resistance while maintaining high strength and load-bearing capacity.

1. The Structural Design Behind Slip Resistance

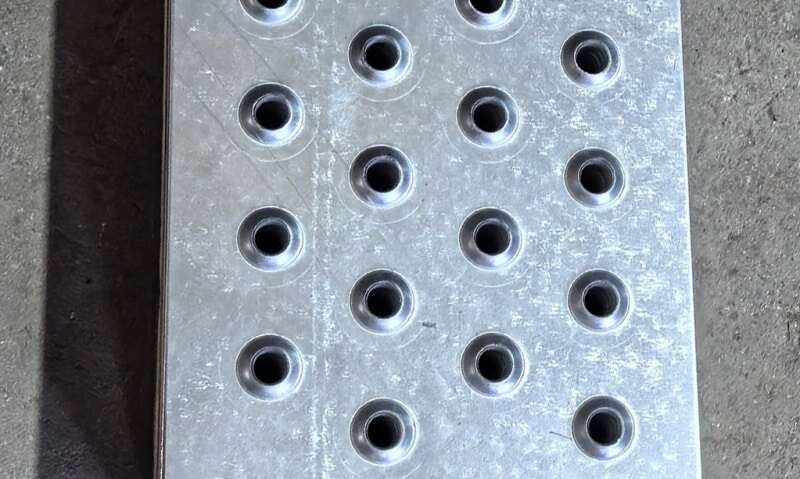

The anti-slip function of perforated safety grating mainly comes from its special punching and forming process. During production, metal sheets such as carbon steel, galvanized steel, stainless steel, or aluminum are perforated and embossed to create raised surfaces or serrated edges. These raised dimples or slots provide additional traction, significantly reducing the risk of slipping even under wet or oily conditions.

Compared to a flat perforated metal sheet, safety grating offers multidirectional grip. The small holes not only provide friction but also allow liquids and debris to drain away quickly, keeping the surface clean and dry.

2. Material Selection and Surface Treatments

The choice of material greatly affects both the slip resistance and longevity of safety gratings. Carbon steel perforated sheets are widely used in heavy-duty industrial areas because of their high strength and durability. Galvanized perforated metal sheets provide excellent corrosion protection, ideal for outdoor walkways and platforms exposed to moisture. For chemical plants or marine environments, stainless steel perforated gratings offer the best resistance to corrosion and oxidation.

Surface finishes such as hot-dip galvanizing or powder coating not only enhance appearance but also increase friction on the surface, providing better grip under foot traffic.

3. Typical Industrial Applications

Perforated safety grating is widely used in:

- Factory floors and maintenance platforms

- Equipment access steps and stair treads

- Catwalks and elevated work areas

- Offshore and power plant walkways

- Vehicle steps and machinery platforms

Its ability to bear heavy loads and resist deformation makes it a reliable choice for facilities where workers frequently move between levels or handle equipment in challenging conditions.

4. Advantages Over Traditional Flooring Solutions

Unlike plain metal plates or solid flooring, perforated safety gratings combine light weight, strength, and ventilation. The open area design not only minimizes the accumulation of liquids and debris but also improves air circulation and light transmission in the workspace. This contributes to a safer and more comfortable working environment.

Additionally, the perforation patterns can be customized to match specific safety requirements. Manufacturers like us offer custom perforated metal sheets with different hole shapes—round, square, or slotted—and various open area ratios to meet distinct project needs.

5. Customization and Flexibility

Every industrial project has different load-bearing and safety standards. Our factory specializes in custom perforated metal panels with flexible options for:

- Thickness and sheet size

- Hole shape and pitch

- Open area percentage

- Surface coating or galvanizing method

Whether you require a single prototype or mass production, we provide complete design flexibility to ensure your perforated safety gratings perform efficiently in their intended environment.

Conclusion

Perforated safety grating is more than just a metal platform—it’s a vital safety solution for industrial environments that demand durability, drainage, and maximum traction. By choosing the right material, hole pattern, and surface treatment, you can significantly enhance workplace safety and operational efficiency.

For customized perforated safety gratings and other perforated metal products, feel free to contact us at info@perfsheet.com for expert consultation and tailored manufacturing solutions.