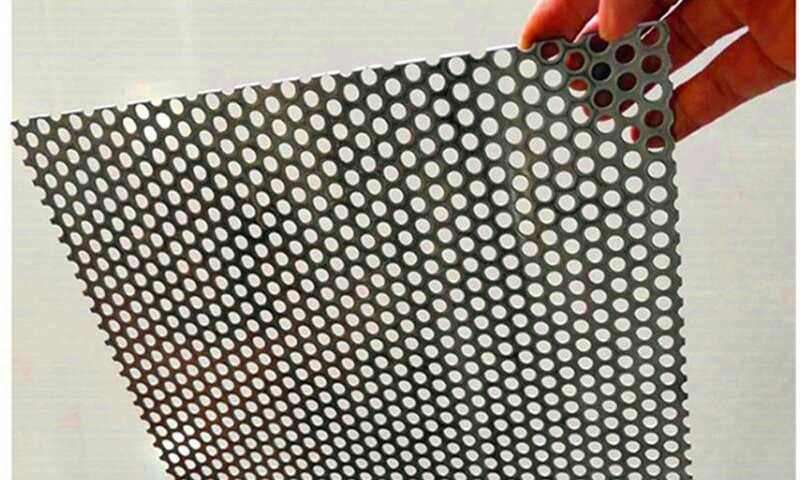

Q235B perforated plates are widely used across ventilation systems, building façades, acoustic barriers, machine guards, and general fabrication work. Engineers often choose Q235B because it delivers a dependable balance of strength, ductility, and cost-effectiveness.

This article provides an in-depth look at the mechanical properties of Q235B steel, how perforation patterns influence performance, and how to select the right perforated plate specification for industrial needs.

Understanding Q235B as a Material

Q235B is a commonly used Chinese carbon structural steel (GB/T 700 standard). Its controlled carbon content (approx. 0.20–0.22%) and low sulfur/phosphorus levels give it stable weldability and forming properties.

Typical mechanical characteristics include:

- Yield strength: about 235 MPa for thin sections

- Tensile strength: typically 370–500 MPa

- Good ductility and weldability due to low carbon

- Predictable forming behavior, ideal for punching and perforating

These baseline properties make Q235B a practical choice for manufacturing perforated panels in different shapes and thickness ranges.

How Perforations Influence Mechanical Performance

Perforating a steel sheet changes its structural behavior. When designing with Q235B perforated plates, the following factors are critical:

1. Open Area Percentage

Higher open area reduces the load-bearing section, stiffness, and weight.

(Useful for ventilation panels but unsuitable for heavy loads.)

2. Hole Shape

- Round holes → best overall structural balance

- Square holes → sharper corners increase stress concentration

- Slots (long holes) → directional weakness, good airflow

3. Hole Pitch & Edge Distance

Tight spacing can reduce fatigue life and may cause tearing during forming.

4. Plate Thickness

Thicker Q235B plates retain higher absolute strength, but tool clearance accuracy becomes more important to avoid edge cracking.

Practical Mechanical Considerations for Engineers

Yield and Tensile Behavior

Q235B retains its nominal yield strength (~235 MPa) in unperforated areas, but effective strength reduces proportionally to open area.

Forming & Welding Suitability

Because Q235B contains low carbon, it welds cleanly and bends uniformly—an advantage when manufacturing perforated components that require frames, folds, or assembly.

Thickness-Dependent Strength Drop

As plate thickness increases (e.g., >16 mm, >40 mm), standards specify slightly lower minimum yield values. Buyers should always check the mill certificate for the actual batch.

Matching Q235B Perforated Plates to Industrial Needs

Architectural Façades & Decorative Panels

- Recommended thickness: 1–6 mm

- Open area: 15–35%

- Common hole types: round, square, decorative

Design Checklist for Buyers and Engineers

Before ordering Q235B perforated plates, confirm:

- Required load capacity or stiffness

- Hole pattern, diameter, spacing and orientation

- Open-area percentage for airflow or filtration

- Thickness aligned with mechanical requirements

- Surface treatment (galvanized, powder-coated, painted)

- Whether stainless or aluminum alternatives are needed

- Availability of mill test certificates

When Q235B Is the Ideal Choice

Q235B perforated metal is a reliable, versatile material for:

- Architectural decoration

- General ventilation

- Machine safety shields

- Acoustic enclosures

- Multi-purpose industrial screening

If the application requires high corrosion resistance or very low weight, stainless steel or aluminum perforated plate variants may be more appropriate.

Conclusion

Q235B perforated plates offer a well-balanced combination of mechanical stability, manufacturability, and cost performance. With proper specification of thickness, open area, and hole geometry, they can meet the demands of a wide range of architectural and industrial projects.

For structural or safety-critical designs, engineers should evaluate effective section properties or consider specialized safety grating solutions.

Contact & Custom Order Support

For inquiries, custom specifications, or prototype support, you can reach us at:

📧 info@perfsheet.com

We support one-piece minimum orders and large-volume production, with full customization of:

- Material (Q235B, galvanized, aluminum, stainless steel, high-manganese, etc.)

- Thickness

- Hole pattern

- Hole size

- Open-area percentage

- Surface treatment