Introduction: The Versatility of Round Hole Perforated Plates in Engineering

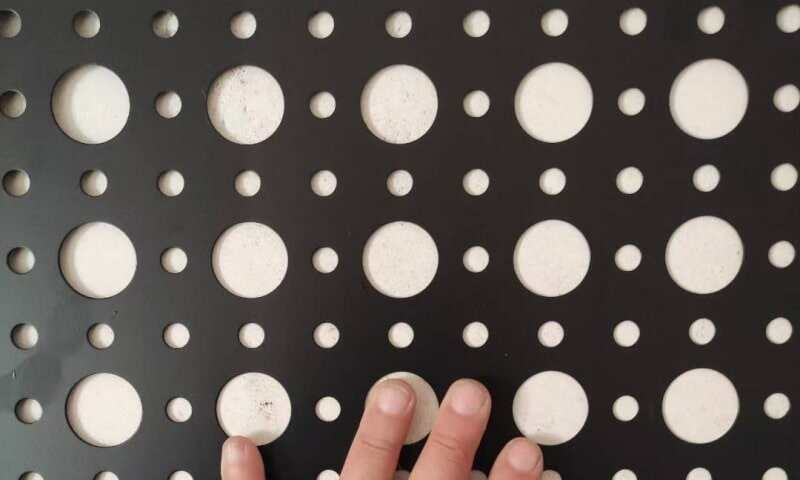

Round hole perforated plates are widely used in various industries for their balance between strength, functionality, and aesthetic appeal. Whether in industrial, architectural, or filtration systems, the specific hole size of these perforated plates plays a key role in optimizing performance for different applications.

Understanding how hole diameter and open area (the ratio of hole area to total plate area) influence the functionality of perforated plates is essential for selecting the best option for your project. This guide covers the most common hole diameter ranges and their applications to help you make an informed decision.

Why Hole Size and Open Area Matter in Perforated Plates

The diameter of the holes in a perforated plate, combined with the open area percentage, determines key performance factors such as airflow, filtration precision, and structural strength. While hole size plays a significant role, the overall open area (how much of the plate is perforated) has a major impact on the following:

- Airflow and Ventilation: A higher open area increases airflow, regardless of hole size, and is crucial in applications like HVAC systems.

- Filtration Precision: Smaller holes, along with the right open area, ensure that only particles of a certain size can pass through, improving filtration precision.

- Strength and Durability: The relationship between hole size, spacing, and the remaining material impacts the plate’s structural integrity and ability to withstand stress.

Let’s take a closer look at the most common hole diameter ranges and their corresponding engineering applications.

1. Small Hole Diameter (1mm to 5mm)

Small holes (1mm to 5mm) are often used when fine control over filtration or airflow is needed. These holes are ideal for applications where precise regulation of particles or airflow is required.

Primary Applications:

- Filtration Systems: Small perforations are commonly used in filters, such as air filters, oil filters, and water treatment screens, where their smaller size allows for finer filtration by trapping smaller particles while maintaining fluid or air flow.

- Electronics: In electronics, these small perforations are found in server racks, control panels, and enclosures to provide ventilation without allowing large particles or debris to enter.

- Decorative Applications: Small-hole plates are used in design for room dividers, light fixtures, and decorative screens, where subtle patterns are desired.

2. Medium Hole Diameter (6mm to 15mm)

Medium-sized holes strike a balance between airflow, structural integrity, and aesthetic appeal. They are widely used in both industrial and architectural applications, providing versatility for various project types.

Primary Applications:

- Architectural Design: Medium holes (6mm to 15mm) are commonly used in building facades, sunshades, and decorative panels, allowing airflow and light while enhancing visual appeal.

- Industrial Machinery: These perforations are ideal for applications in machinery, such as conveyor belts, safety guards, and sorting machines, where the holes facilitate the passage of debris or allow for ventilation.

- Acoustics: Medium holes, combined with sound-absorbing materials, are often used in noise control applications like theater panels, office partitions, and acoustic ceilings.

3. Large Hole Diameter (16mm to 25mm+)

Large holes (16mm and larger) are typically used when maximum open area is required. These plates are perfect for applications where high airflow or visibility is crucial.

Primary Applications:

- Heavy-Duty Industrial Applications: In industries like mining, quarrying, and recycling, large holes are used to separate materials or allow larger debris to pass through with minimal obstruction.

- Safety Barriers: Large-hole perforated plates are commonly used in machine guards, factory partitions, and bridge railings, offering visibility while preventing larger objects from passing through.

- Outdoor Architecture: These plates are also used in outdoor structures such as parking garage facades, sunshades, and canopies, where their larger holes allow for airflow while providing shade.

Customizing Your Perforated Plates

While the hole diameter ranges above serve as useful guidelines, many projects require specific, non-standard specifications. Customizing your perforated plates provides multiple benefits, such as:

- Tailored Hole Sizes: Custom tooling allows for precise hole diameters that meet your unique design requirements.

- Material Thickness Variability: The correct plate thickness ensures structural integrity, especially when working with larger holes or demanding applications.

- Custom Patterns and Spacing: Choosing the right hole pattern (e.g., staggered or straight rows) ensures the material’s strength and visual appeal meet your needs.

Whether you need a single prototype or large-scale production, custom perforated plates can be manufactured to your precise specifications.

Conclusion: Get the Right Perforated Plate for Your Project

Choosing the right round hole perforated plate requires careful consideration of hole diameter, open area, material, and thickness. By understanding how these factors impact performance, you can ensure that your perforated plate will meet the specific needs of your project—whether it’s for a filtration system, industrial machinery, or architectural design.

If you’re ready to discuss your project or need a custom solution, don’t hesitate to contact us. Our team specializes in providing high-quality, custom perforated metal sheets tailored to your exact specifications.

Need custom perforated plates? Get in touch today!

Email: info@perfsheet.com