When a project needs corrosion resistance, attractive finish and good formability without the premium of marine-grade alloys, 304 Perforated Stainless Steel Sheets are often the best compromise. From architectural sunscreens and decorative facades to food processing screens and HVAC filters, 304 gives you broad suitability across industrial and commercial uses. This guide helps engineers, purchasers and designers pick the right 304 perforated sheet for performance, cost and manufacturability.

Why choose 304 for perforated sheets?

- Balanced corrosion resistance. 304 (commonly called 18/8 stainless) contains roughly 18% chromium and 8% nickel, giving reliable resistance to atmospheric corrosion and many chemicals found in indoor and light outdoor environments.

- Excellent formability and weldability. 304 is easy to punch, bend and weld, which helps keep fabrication time and scrap low.

- Good surface finish. It accepts mechanical and electropolishing, producing attractive architectural surfaces.

- Cost-effective. Less expensive than 316 while covering most non-marine applications.

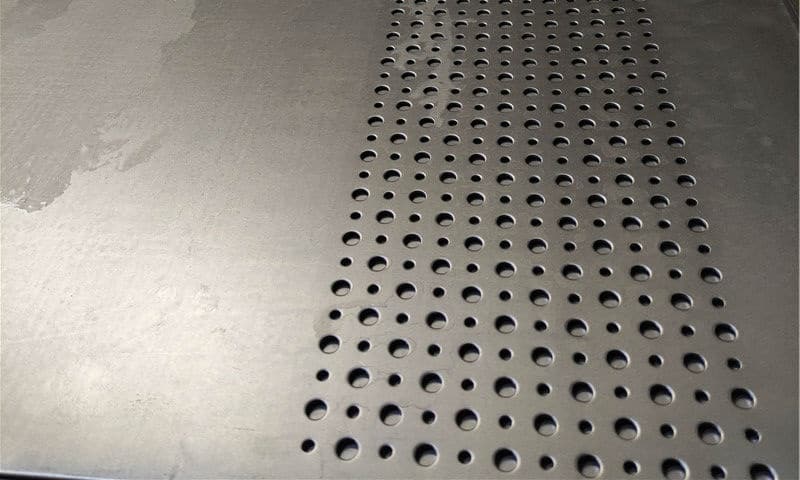

Stainless Steel Perforated Metal Sheets

Stainless steel perforated sheet is a commonly used material in both architectural and industrial applications. It offers stable corrosion resistance and good fabrication flexibility.

Hole patterns, open area, dimensions and surface finishes can all be customized according to project drawings. Typical uses include facades, ventilation and filtration, partitions and equipment protection.

Feel free to view the product details or contact us for samples and pricing information.

Typical applications

- Architectural screens, sunscreens and balustrades

- Interior design: partitions, ceiling tiles, fixtures

- Food and beverage processing equipment (non-extreme corrosive situations)

- HVAC, filtration, and acoustic panels

- Walkways, machine guards and safety panels (when combined with appropriate thickness and support)

Common hole patterns and what they mean for selection

- Round holes — Most economical, best structural integrity for a given open area. Widely used for filtration and decorative work.

- Square/Slotted holes — Allow higher open area and different flow characteristics; slots are common in drainage or linear ventilation.

- Staggered vs. Straight pitch — Staggered patterns increase free area and reduce visible repeating patterns, often improving strength-to-open-area ratio.

- Special shapes (teardrop, fish-eye, crocodile) — Used for anti-slip flooring or specific aesthetic/functional needs.

Selecting the pattern: prioritize functional needs (airflow, light, drainage, slip resistance) first, then aesthetics and cost.

Thickness, open area and structural capacity

- Thickness (gauge): Thinner 304 sheets (thin gauges) are cheaper and easier to form but need backing/support for load-bearing uses. For treads, platforms or structural guards choose thicker gauges or combine with supports.

- Open area: The % open area (hole area ÷ total area) controls flow and visibility. Higher open area increases flow but reduces stiffness. Typical ranges: low (10–25%), medium (25–45%), high (45%+).

- Rule of thumb: For pedestrian platforms choose lower open area and thicker gauges; for filtration or acoustic baffles use higher open area with backing or framing.

Manufacturing methods — pros and cons

- Mechanical punching (punch press): Fast and economical for standard patterns and medium–high volumes. Best for round and common shapes.

- CNC laser cutting: Precise, flexible for custom shapes or small batches; slower and more costly per piece for large volumes.

- Waterjet / plasma: Useful for thick plates or when heat-affected zones must be avoided; slower and pricier.

- Roll forming / continuous punching: Efficient for very long runs or coil-fed production.

Choose punching for standard orders and cost efficiency; choose laser or waterjet for custom patterns, prototype runs or tooling-free designs.

Surface finishes and post-treatments

- 2B / cold-rolled finish: Smooth, common for industrial use.

- No.4 brushed: Attractive for architectural interiors.

- Polished / mirror: For high-end decorative needs.

- Passivation: Removes free iron and improves corrosion resistance — recommended for exposed or sanitary applications.

- Electropolishing: Smooths burrs and improves corrosion resistance and hygiene (useful for food/medical contexts).

For outdoor or architectural work, specify passivation and consider electropolishing if aesthetics and longevity matter.

304 vs 316 — when to upgrade

If the project will see chloride-rich environments (coastal, salt spray, some chemical processes), upgrade to 316 for better pitting and crevice corrosion resistance. Choose 304 for general indoor, urban outdoor and most food-processing applications where extreme chloride exposure is not expected.

Practical buying checklist (quick)

- Environment: indoor / outdoor / chemical exposure / food contact

- Pattern & open area: round/square/slot + target % open area

- Thickness & support: confirm load requirements, choose gauge accordingly

- Sheet size & edge finish: maximum sheet width, deburred/finished edges?

- Surface finish & treatments: 2B / No.4 / passivation / electropolish

- Quantity & lead time: standard tooling vs custom; ask for prototypes for new patterns

- Tolerance and flatness: specify if critical for assembly

- Traceability / certificates: mill test report (MTR), material grade certification if required

Handling, fabrication and maintenance tips

- Avoid introducing carbon steel contamination. Use clean tools and separate storage to prevent rust spots.

- Welding: 304 welds well; specify filler material compatible with 304 to avoid sensitization.

- Cleaning: routine cleaning with mild detergent and water; for stubborn stains use stainless-specific cleaners. Avoid chlorine bleach or overly acidic cleaners.

- Passivation: consider post-fabrication passivation to restore corrosion resistance after welding or cutting.

Typical technical notes

- Magnetism: Annealed 304 is essentially non-magnetic; some magnetism can appear after cold working.

- Temperature: 304 retains strength at elevated temperatures and is commonly used across a wide temperature range; for sustained high-temperature service consult material engineers.

- Formability: Very good — suitable for deep drawing, bending and forming operations.

Sample specification template

- Material: 304 stainless steel perforated sheet (ASTM A240 / EN 10088 grade 1.4301)

- Thickness: __ mm

- Sheet size: __ mm × __ mm

- Hole pattern: round / square / slot — hole diameter __ mm / slot __ × __ mm

- Pitch: __ mm (staggered / straight)

- Open area: __ % (approx.)

- Surface finish: 2B / No.4 / polished

- Edge finish: deburred / folded / hemmed

- Post-treatment: passivation / electropolish (if required)

- Quantity: __ pcs

- Tolerance: flatness __ mm, hole location tolerance __ mm

- Certification: MTR required (Y/N)

Frequently asked questions

Q: Is 304 perforated stainless suitable for outdoor use?

A: Yes — for most non-marine outdoor environments 304 performs well. Near saltwater or in high-chloride atmospheres, 316 is safer.

Q: Can I weld perforated 304 plates?

A: Yes. Welding is routine; specify post-weld cleaning and passivation if corrosion resistance is critical.

Q: What are typical lead times?

A: Lead times depend on pattern complexity and quantity. Standard patterns and common sizes are fastest; custom tooling or low-volume laser work takes longer.

Q: How do I reduce burrs around holes?

A: Request deburring, edge rolling/hemming, or electropolishing in your order.

Final tips from a fabricator’s perspective

- Start with a clear functional brief (load, airflow, visibility) — it helps narrow pattern/thickness choices quickly.

- For architectural jobs, request physical samples of the pattern and finish — photos don’t always tell the full story.

- Keep installation details in mind: how the panel will be supported or fastened often dictates thickness more than the aesthetic.

Need a quote or a sample? When you’re ready, provide your RFQ using the sample specification template above (material, thickness, hole pattern, finish and quantity) and ask your supplier for drawings and a sample cut. Good suppliers will offer cut samples or small prototypes to confirm look and fit before full production.