Square-hole perforated steel plates are widely used in industrial equipment, air-handling systems, filtration, acoustic control, and modern building façades. Beyond basic punching, manufacturing these plates involves precise control of raw materials, tooling, punching parameters, post-processing, and final inspection.

This article explains the complete production workflow as well as practical design principles for hole sizing, pitch spacing, open-area ratio, and arrangement patterns. Understanding these fundamentals helps engineers specify cost-effective perforated steel plates that meet structural and functional needs.

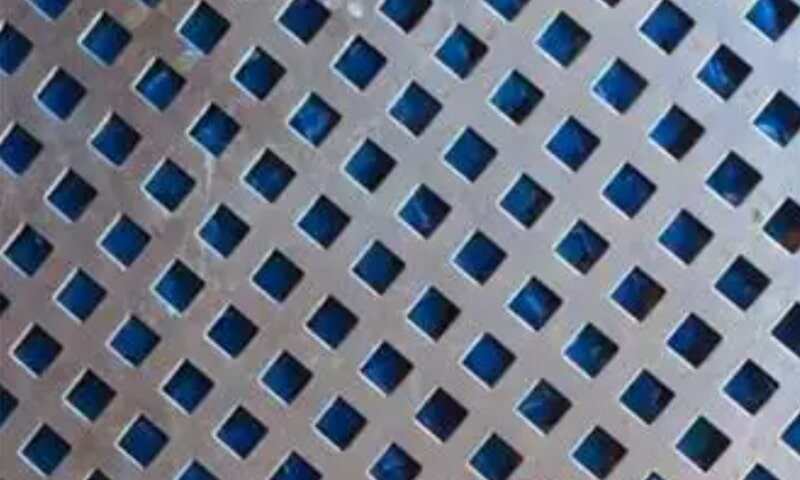

Square Hole Perforated Metal Sheets

Square hole perforated metal sheets are versatile and commonly used in filtration, acoustics, and decorative applications. They offer a clean, geometric hole pattern.

Manufacturing Workflow: From Steel Sheet to Finished Perforated Plate

Quality begins long before the first hole is punched. Each step affects accuracy, appearance, and performance.

1. Raw Material Selection: Establishing a Stable Foundation

Raw sheet quality determines the stability of hole geometry. Suitable materials include carbon steel, stainless steel (304/316L), galvanized substrates, and aluminum alloys.

Engineers check:

- thickness tolerance

- surface flatness

- coating condition (if applicable)

- hardness and mechanical properties

Uneven thickness or surface defects can lead to punching deformation or inconsistent square-hole dimensions.

2. Tooling Preparation: Controlling Hole Precision

Punch and die sets determine the accuracy of hole size and spacing. For square-hole perforation, mold characteristics require special attention:

- precise clearance between punch and die

- perpendicular positioning to avoid tilted hole walls

- wear-resistant tool material such as HSS or carbide

Before mass production, trial punching verifies:

- hole dimension tolerance

- burr height

- punching pressure and speed

- sheet deformation or warping

Small adjustments here prevent expensive production defects later.

3. Perforation Forming: Choosing the Right Method

Common perforation methods include:

Stamping perforation

- most cost-effective for high-volume production

- must control punch speed and tonnage to prevent distortion

Laser perforation

- minimal thermal deformation

- excellent precision for small holes and customized layouts

Plasma perforation

- suitable for thicker plates and large hole sizes

For thicker gauges, multi-step punching helps distribute stress and protects tooling.

4. Post-Processing and Surface Finishing

After perforation, plates may require:

- deburring to remove sharp edges

- leveling or flattening to eliminate punching distortion

- surface protection: galvanizing, powder coating, painting, anodizing, or passivation

- cutting to final panel size

These steps directly affect corrosion resistance, safety, and appearance for architectural use.

5. Final Inspection and Quality Assurance

Inspection items typically include:

- hole size and spacing verification

- open-area ratio calculations

- burr height and edge smoothness

- surface defect inspection (scratches, rust, uneven coating)

- tensile or bending tests for structural applications

Only products passing every inspection requirement enter final packaging and shipment.

Designing Square-Hole Patterns: Functional and Economic Principles

Hole pattern decisions should balance functionality, manufacturability, and cost.

Functional Design Objectives

Different applications require tuned open areas:

- ventilation & cooling → larger open area ratio

- filtration & screening → hole size matches particle size

- acoustics → small holes improve medium-high-frequency absorption

- protective covers → prioritize strength and durability

The functional objective determines hole dimension, spacing, and plate thickness.

Manufacturability Considerations

Designers should avoid patterns that slow production or damage tooling:

- hole side length ideally ≥ 1.5× sheet thickness for punching

- web width (pitch−hole size) should be ≥ material thickness

- staggered patterns increase open area but require higher mold precision

Inadequate web width can cause cracking or deformation during punching.

Economic Principles

To control cost while ensuring quality:

- avoid unnecessary hole-size variety in a single plate

- use standard tooling dimensions when possible

- optimize hole spacing to reduce hole count and punching time

- select cost-effective coatings when corrosion exposure is moderate

Balancing material and design leads to more predictable unit pricing.

Standardization and Flexible Customization

Catalog standards improve production efficiency, but engineers may require:

- special hole sizes

- modified open-area ratio

- unique patterns for architectural aesthetics

- thicker substrates for heavy-duty machinery

Flexible customization meets these needs while retaining production feasibility.

Conclusion and Next Steps

Square-hole perforated steel plates require careful planning—from material sourcing to mold design, hole geometry, post-processing, and final inspection. Understanding both hole-pattern principles and manufacturability allows engineers to specify products that balance durability, flow, acoustics, cost, and appearance.

If you need customized square-hole perforated steel plates, including one-piece orders or mass production in various thicknesses, materials, hole sizes, and open-area ratios, reach out anytime.

Contact Us

For drawings, RFQs, or technical consultations:

Email: info@perfsheet.com

We will reply promptly with design assistance and pricing options.