Introduction

Cleanliness, precision, and efficiency define modern food processing and medical environments. From production lines to sterilization rooms, every component must support hygiene and structural reliability. Among these components, stainless steel perforated metal sheets play an indispensable role.

They combine strength, corrosion resistance, and precise open-area control, enabling engineers and designers to meet strict safety and ventilation requirements. At Anping Senchi Metal Mesh Products Co., Ltd., we’ve developed perforated metal solutions tailored to these hygiene-critical industries, where performance and cleanliness are equally important.

Why Stainless Steel?

The unique properties of stainless steel make it the preferred material for environments requiring regular cleaning, sterilization, and chemical resistance:

- Corrosion Resistance – Essential for equipment exposed to moisture, steam, or disinfectants.

- Hygienic Surface – Smooth finishes reduce bacterial adhesion and simplify cleaning.

- Mechanical Strength – Even with perforation, the material maintains rigidity and structural support.

- Customizability – From hole patterns to thickness, it can be precisely designed for airflow, filtration, or drainage needs.

Applications in the Food Industry

In food production, stainless steel perforated metal sheets are used for processing, filtering, and safety.

1. Filtration and Separation

Micro-perforated sheets are ideal for separating ingredients, sieving powders, or filtering liquids. Their consistent hole geometry ensures accurate particle control and stable throughput.

2. Airflow and Ventilation Panels

Perforated stainless steel helps maintain proper air circulation in storage and drying areas, preventing condensation and contamination.

3. Equipment and Conveyor Systems

Custom perforated trays, strainers, and conveyor belts allow drainage and improve heat distribution during baking or drying. When strength with hygiene is required, stainless steel offers longer service life than aluminum or galvanized alternatives.

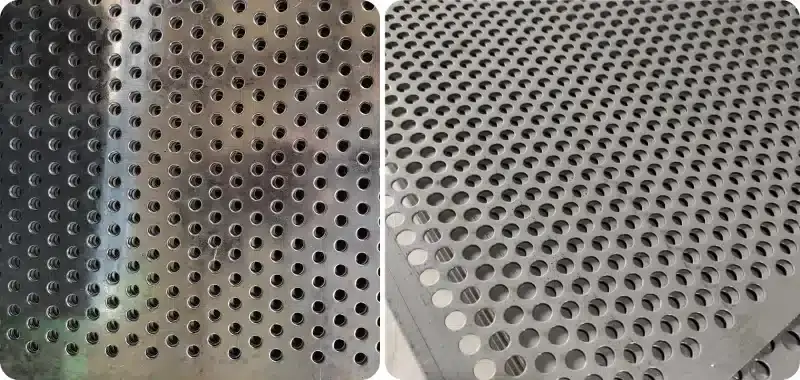

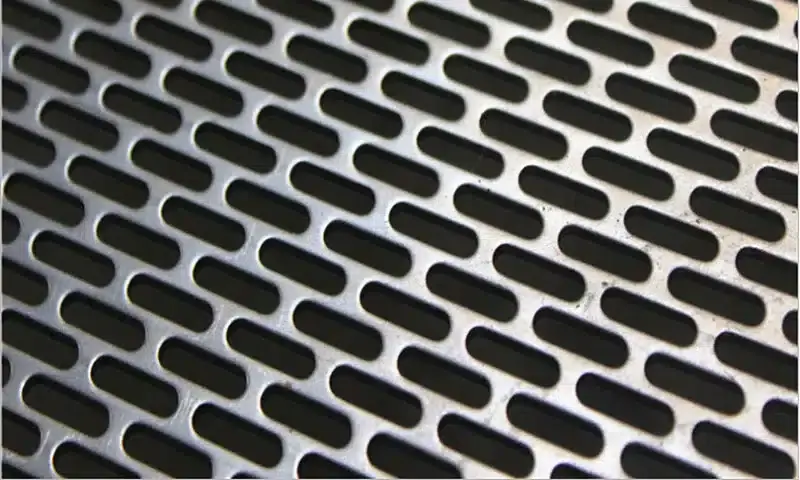

Senchi’s production capabilities include round, slotted, and hexagonal perforations to achieve specific flow and weight requirements. The company’s Micro Perforated Metal Sheets product range is frequently chosen for precision filtration and fine-grain processing.

Applications in the Medical and Healthcare Sectors

Medical facilities demand materials that maintain sterile conditions under rigorous cleaning and disinfection cycles. Stainless steel perforated sheets are trusted for their hygienic design and mechanical stability.

1. Cleanroom Airflow Systems

Perforated panels are used in ventilation and filtration units to regulate laminar airflow while minimizing dust accumulation.

2. Sterilization Trays and Equipment Casings

Instrument trays made from perforated stainless steel allow steam or chemical sterilants to pass through efficiently, ensuring thorough cleaning and quick drying.

3. Safety Platforms and Flooring

Non-slip perforated panels or Perforated Safety Grating systems are installed in laboratories and operating areas to prevent slips while maintaining fluid drainage.

Each of these applications benefits from stainless steel’s balance between hygiene, airflow, and mechanical strength.

Design Considerations and Customization

Choosing the right stainless steel perforated metal sheet requires balancing multiple parameters:

- Material Grade – 304 or 316 for enhanced corrosion resistance in sterilization zones.

- Hole Type – Round holes for universal use, slotted for drainage, and micro-perforation for filtration.

- Open Area Ratio – Determines airflow or drainage capacity.

- Thickness and Strength – Must align with the equipment’s load-bearing needs.

- Surface Finish – Brushed or passivated finishes improve sanitation and reduce contamination risk.

At Senchi, every order—whether a single prototype or bulk production—is handled with precision tooling and strict quality control. Engineers can specify hole shapes, spacing, sheet dimensions, and finishing treatments to match operational requirements.

Beyond Stainless Steel: Alternative Materials

While stainless steel remains the top choice for hygiene, other perforated metals such as aluminum perforated metal sheets or galvanized perforated metal sheets may be used for lighter, non-corrosive applications like architectural facades or machine guards.

Senchi provides technical guidance to help clients select the most suitable material according to the project’s environment and cost considerations.

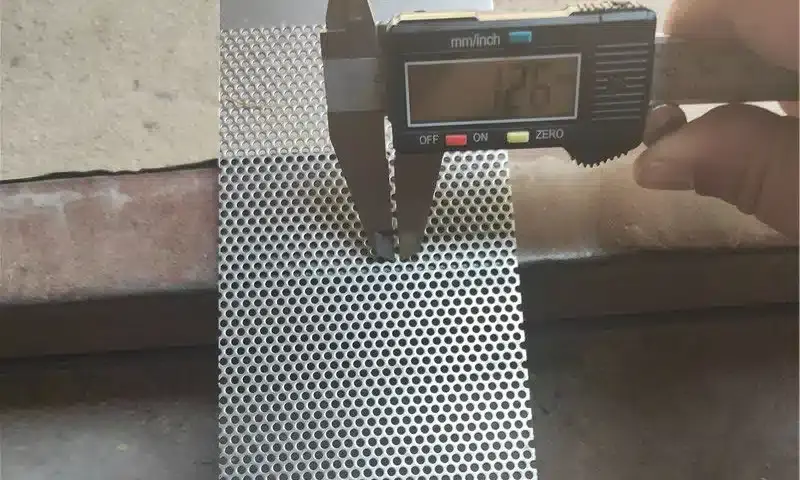

A Practical Example

One of Senchi’s clients in the dairy processing sector required perforated panels for air filtration and drainage that would withstand high-pressure washdowns. By using 316 stainless steel sheets with 3 mm round holes and a 35% open area, the customer achieved excellent durability, reduced maintenance time, and improved hygiene standards across their facility.

Quality Assurance and Compliance

Senchi’s manufacturing process follows international quality standards and includes multiple inspections—from raw material verification to final finishing. The company ensures all perforated products meet hygiene and durability criteria required for food and medical usage.

Conclusion

From filtration systems and ventilation covers to sterilization trays and safety flooring, stainless steel perforated metal sheets provide unmatched performance in food and medical environments. Their adaptability, cleanability, and strength make them an essential part of hygienic design.

At Anping Senchi Metal Mesh Products Co., Ltd., we continue to refine perforation technology and expand customization options to meet diverse industry needs.

If you’re planning a new installation or looking to optimize your existing setup, our technical team can provide recommendations based on years of manufacturing experience.

Contact us today at info@perfsheet.com to discuss your next project or request a sample of our stainless steel perforated metal solutions.