Introduction

Perforated metal sheets have become an essential part of modern industrial and architectural design. From decorative facades to filtration systems, these versatile sheets combine both function and form. Among various materials, 304 stainless steel perforated metal sheet stands out for its exceptional strength, corrosion resistance, and aesthetic appeal.

Whether used for interior decoration, soundproof panels, or ventilation covers, choosing the right grade and perforation pattern can significantly influence performance and longevity.

What Is 304 Stainless Steel Perforated Metal Sheet?

A 304 stainless steel perforated metal sheet is made by punching or drilling precise holes into high-quality 304 stainless steel plates. This material, composed mainly of chromium and nickel, offers outstanding resistance to rust, heat, and chemical exposure.

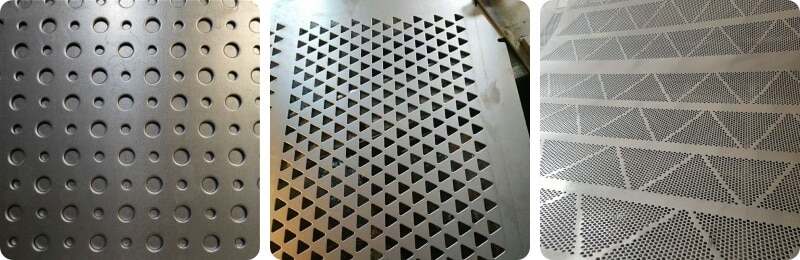

Depending on the project, the hole pattern can vary—round holes, square holes, or slot holes—each serving a different purpose in airflow, strength, or appearance.

Key Material Properties of 304 Stainless Steel

The appeal of 304 stainless steel lies in its well-balanced combination of mechanical and chemical properties:

- Excellent Corrosion Resistance:

Thanks to its 18% chromium and 8% nickel content, 304 steel can withstand moisture, acids, and many industrial chemicals. This makes it ideal for outdoor installations or humid environments. - High Strength and Durability:

It maintains good tensile strength even at high temperatures and resists deformation over long periods. - Ease of Fabrication:

304 stainless steel is easy to cut, weld, and polish, making it suitable for customized perforated designs. - Hygienic and Easy to Clean:

Its non-porous surface makes it perfect for applications in food processing or medical equipment.

For alternative materials that prioritize lightweight features, consider the Aluminum Perforated Metal Sheet, which offers good corrosion resistance with lower weight.

Advantages of 304 Stainless Steel Perforated Sheets

The benefits of using 304 stainless steel go beyond its mechanical strength:

- Long Service Life:

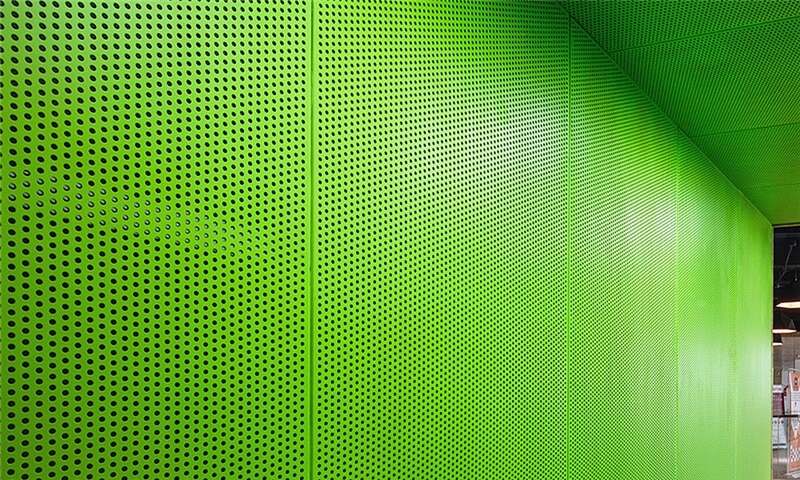

Resistant to corrosion and oxidation, it can perform reliably in both indoor and outdoor environments. - Modern Aesthetic:

Its clean, metallic finish makes it a popular choice for architectural and interior design projects. - Low Maintenance:

Unlike mild steel or painted panels, it requires minimal upkeep. - Wide Perforation Choices:

Available in various hole types, such as Round Hole Perforated Metal Sheet or Slot Hole Perforated Metal Sheet, users can tailor the design based on functionality and appearance.

Applications and Selection Tips

304 stainless steel perforated sheets are widely used in:

- Architectural decoration: building facades, ceilings, sunshades

- Industrial use: filters, guards, noise-control panels

- Transportation: ventilation covers, acoustic barriers

- Food and chemical processing: hygienic filtering and separation

When selecting your perforated metal sheet, consider the following:

- Hole Size & Open Area: Affects airflow, filtration efficiency, and light transmission.

- Thickness: Determines strength and rigidity.

- Finish: Polished, brushed, or mill finish for different visual effects.

For heavy-duty environments such as mining or impact-prone zones, the High Manganese Steel Perforated Metal Sheet may be a better choice due to its superior wear resistance.

Why Choose Custom Perforated Metal Sheets from China

At Anping Senchi Metal Wire Mesh Co., Ltd., we understand that every project has its own design and performance requirements.

Our factory in Hebei, China, offers complete customization in hole size, thickness, pattern, material, and open area ratio, supporting both small orders and mass production.

Whether you need stainless steel, galvanized, or Carbon Steel Perforated Metal Sheet, we provide flexible manufacturing and global delivery to ensure your specifications are met with precision.

Conclusion

The 304 stainless steel perforated metal sheet is an ideal solution for projects demanding durability, elegance, and adaptability.

By understanding its material properties and selection criteria, you can ensure the best results for both functional and decorative applications.

📧 For inquiries or custom specifications, contact us at info@perfsheet.com.