Stamped anti-slip steel plates are a go-to solution for improving worker safety and equipment access across industries. The hole pattern on a plate isn’t just cosmetic — it determines traction, drainage, durability, and how well the surface performs in mud, oil, snow, or heavy foot traffic. Although these plates are easy to produce in many sizes and materials, the choice of hole type is one of the most important decisions when specifying anti-slip metal.

Below are the three most frequently produced hole patterns used in stamped anti-slip steel plates, presented in order of practical application and overall recommendation.

Serrated Oval Holes — The Most Widely Used and Recommended

Serrated oval holes combine an elongated opening with raised, saw-tooth edges that “bite” into boot soles. This design delivers extremely reliable traction in the toughest working conditions and is why serrated patterns are the most commonly recommended option.

Key advantages

- Superior grip in mud, snow, and steep inclines

- Effective on oily or wet surfaces where aggressive bite is needed

- Excellent for high-traffic and heavy-wear locations

- Good drainage due to elongated openings

- Small price difference compared to other hole types, making serrated a cost-effective choice

Common applications

- Mining and quarry walkways

- Outdoor machinery platforms and access steps

- Forklift ramps and loading areas

- Agricultural and construction equipment platforms

When safety and consistent performance are priorities, serrated oval plates are usually the safest recommendation.

Circular Raised Holes — Dense Traction Points for Wet or Oily Floors

Circular raised holes feature evenly distributed raised dimples. This pattern creates many small contact points that improve traction under vertical load and help reduce slipping on smooth or contaminated surfaces.

Key advantages

- Strong, even grip across the plate surface

- Good resistance to slipping on oil or water-contaminated floors

- Solid mechanical strength because of circular geometry

- Suited to both light and medium-heavy load applications

Common applications

- Industrial workshops and manufacturing floors

- Food processing or maintenance areas with frequent spills

- Truck ramps and equipment steps where liquids are present

Circular raised holes are a reliable, balanced choice when you need even traction and structural performance.

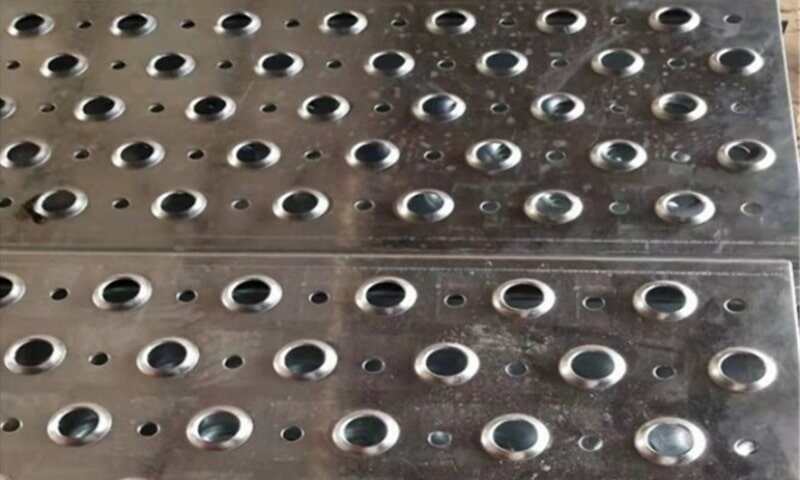

Raised-Rim Oval Holes — Elongated Openings with a Raised Edge

The oval holes shown in your images are also formed with a raised rim — not flat openings. That raised rim adds friction and improves grip while maintaining a larger open area for drainage and debris pass-through. Compared with serrated and circular raised styles, raised-rim ovals are less aggressive in bite but still provide dependable anti-slip performance where heavy, jagged traction is not required.

Key advantages

- Larger opening area for efficient drainage of dirt and water

- Raised rim increases slip resistance versus flat punched holes

- Good for mobile platforms and vehicle-related applications

- Slightly less aggressive on boot soles than serrated patterns

Common applications

- Construction vehicles and trailers

- Mobile equipment access steps

- Medium-duty walkways where debris clearance is a priority

Although raised-rim oval holes are used less broadly in heavy-duty industrial sites, they remain the preferred choice for many transport and equipment-mounted platforms.

How to Choose Between Serrated, Circular Raised, and Raised-Rim Oval Holes

Even though prices between these hole types differ very little, you’ll want to match the pattern to the environment and safety needs. Here’s a quick decision guide:

- Maximum traction and harsh outdoor conditions → Serrated oval holes. Best overall choice for aggressive bite and wear resistance.

- Frequent liquid exposure or slip-prone indoor floors → Circular raised holes. Many small grip points handle oily or wet conditions well.

- Vehicle-mounted platforms, trailers, or where larger drainage is needed → Raised-rim oval holes. Good balance of drainage and grip for mobile applications.

Also consider plate thickness, material (carbon steel, stainless steel, aluminum), and the open-area ratio when specifying plates — these factors impact load capacity, longevity, and how harsh environments affect the surface.

Final Recommendations

Because the price difference among serrated, circular raised, and raised-rim oval patterns is minimal, the safest and most cost-effective recommendation for general industrial and outdoor use is the serrated anti-slip plate. It offers the broadest application range, the highest traction performance, and excellent long-term wear properties.

If your project is vehicle-specific or requires larger drainage openings, raised-rim oval holes can be ideal. For facilities with frequent spills or smooth-footwear scenarios, circular raised holes provide balanced, dependable performance.

If you’d like help choosing the right plate for a specific application (material, thickness, hole size, open-area ratio), I can draft spec suggestions you can use directly in RFQs or product pages.

Ready to order or need a custom quote? Contact us with your required dimensions, material, and application details and we’ll respond quickly with recommendations and pricing.

Email: info@perfsheet.com