Why Spec Sheets Matter (and Why They’re Often Misread)

If you’ve ever compared quotes from multiple suppliers and wondered why “the same” round hole perforated sheet comes back with different pricing, lead times, or even different samples—nine times out of ten, the spec sheet is the reason.

In real-world production, small details like hole pitch, edge margins, or material temper can change tool selection, yield, flatness, and how the sheet behaves after forming. The goal of this guide is simple: help newer buyers read a round hole perforated metal sheet spec sheet with confidence—and help experienced engineers reduce back-and-forth during RFQs.

Round Hole Perforated Metal Sheets

Custom perforated metal sheets with precise hole patterns in various materials: stainless steel, aluminum, galvanized steel, carbon steel, copper, brass, and plastic. Durable and corrosion-resistant.

Perfect for architectural screens, machinery guards, acoustic panels, and decorative elements. Factory-direct pricing with cutting/bending services. Request quote or sample today.

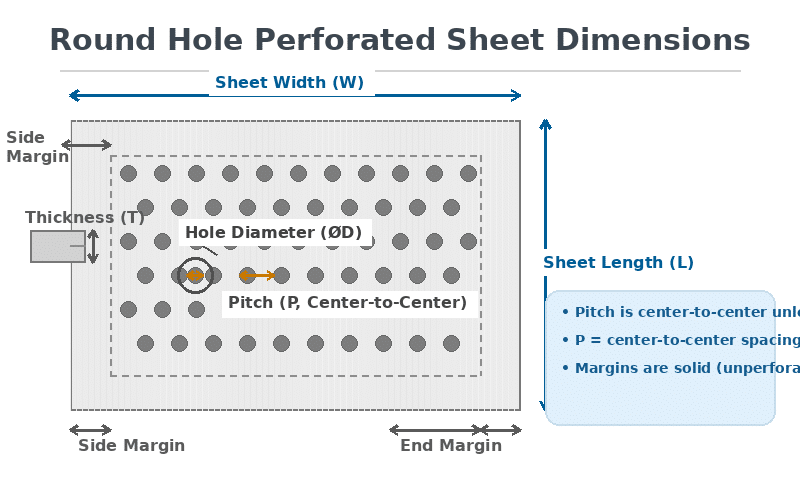

Start With the Sheet Size (Width × Length)

Most spec sheets list overall sheet size first, usually as:

- Width × Length (for example, 48″ × 96″)

- Sometimes written as W × L

- For coils, you may see coil width and coil length/weight

What to double-check

- Is the listed size the overall blank size or the effective perforated area?

Some drawings show a perforated “field” inside a solid border. The sheet might be 48″ × 96″, but the perforated field could be smaller. - Is the sheet cut to size or supplied as a standard stock size?

Custom blanks can reduce your in-house cutting time, but they also require clear tolerances and edge definitions.

Thickness: Base Metal Thickness vs. “After Perforation”

Thickness should be specified as base metal thickness (the material before holes are punched), typically in:

- inches (e.g., 0.063″)

- millimeters (e.g., 1.5 mm)

Common confusion to avoid

- Gauge isn’t universal across materials. A “16 ga” in stainless can differ from carbon steel depending on the standard used.

- Perforation can affect perceived stiffness. Two sheets with the same base thickness may feel very different if their open area is different.

Material: Specify the Grade, Not Just the Metal Type

“Stainless steel” isn’t enough detail for manufacturing or performance. A good spec calls out:

- Alloy/grade (e.g., 304, 316)

- Finish (2B, #4 brushed, BA, etc.)

- Condition/temper (annealed, half-hard, etc. when relevant)

Why it matters in purchasing

If your application is food processing, pharma, marine, or chemical exposure, the difference between 304 and 316 can be the difference between a long service life and early corrosion. For buyers sourcing Stainless Steel Round Hole Perforated Sheets, it’s also worth noting that certain finishes and thicknesses may impact availability and lead time.

Hole Diameter: How the Hole Size Is Defined

Hole size is usually the diameter of each round hole, for example:

- Ø0.125″ (diameter one-eighth inch)

- Or written as 0.125″ DIA

Practical notes from the shop floor

- Hole diameter has tolerance. If you’re using the sheet for filtration, airflow, or fastener clearance, don’t assume the nominal hole size is exact.

- If the hole size is close to the material thickness, manufacturing constraints become more important. A clear spec helps prevent distortion and burr concerns.

Hole Spacing: Pitch (Center-to-Center) Must Be Crystal Clear

Pitch is one of the most misunderstood items in round perforated sheet specs.

Center-to-center pitch (the “real” spacing)

Most industrial specs define pitch as the distance from the center of one hole to the center of the next hole.

- Straight pitch: center-to-center spacing in a grid

- Staggered pitch: center-to-center spacing along staggered rows

If a spec says 0.187″ pitch, that typically means center-to-center, not edge-to-edge.

Edge-to-edge spacing (sometimes called “web”)

Some buyers think pitch means the metal “bridge” between holes. That bridge is actually:

- Web = Pitch − Hole Diameter

This is critical for strength. If you need the sheet to support load, resist denting, or stay flatter after punching, the web dimension matters as much as hole size.

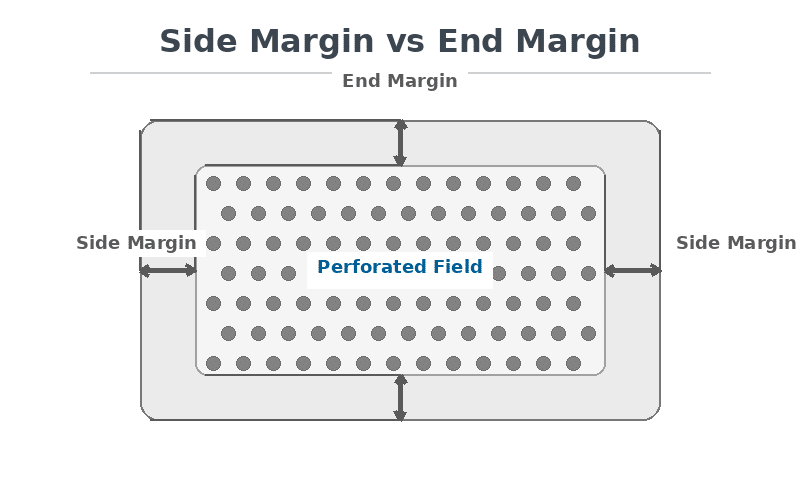

Edge Margins: Side Margin and End Margin (Don’t Skip This)

Round hole perforated metal sheets often have unperforated borders. These borders affect mounting, sealing, and appearance.

Side margin vs. end margin

- Side margin: unperforated band along the width edges

- End margin: unperforated band along the length ends

A complete spec should say:

- margin dimension (e.g., 1.00″)

- whether margins are required on all sides or only selected edges

- whether the perforation pattern is centered or biased to one side

Why margins affect cost and usability

Margins can reduce open area and change how many sheets fit in a nest during production. On the application side, margins can make installation cleaner—especially for architectural panels, guards, and enclosures.

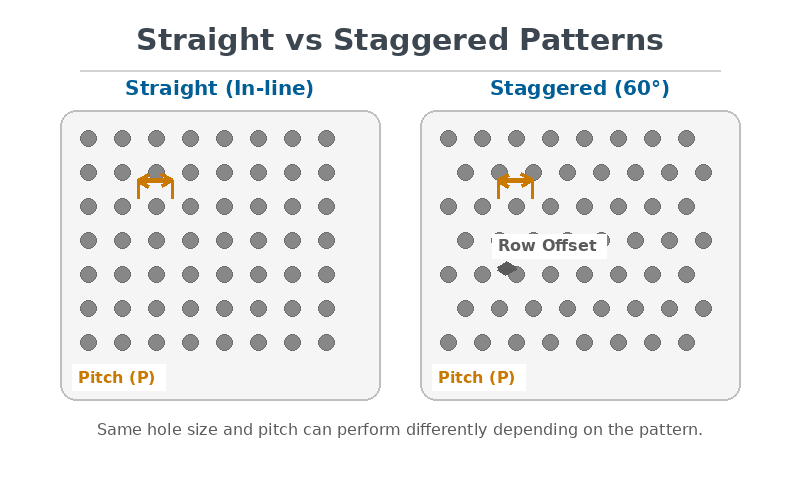

Pattern Layout: Straight vs. Staggered (and Why Engineers Choose One)

Two common arrangements appear on spec sheets:

Straight line (in-line) pattern

Holes align in rows and columns. This is often used when:

- alignment matters visually

- consistent support lines are needed

- parts will be laser-cut around the pattern

Staggered pattern (60° or triangular layout)

Holes are offset row-to-row. This is popular because it can provide:

- higher open area for airflow

- better distribution

- a different balance of strength vs. openness

If your drawing says “staggered,” it should still specify pitch clearly. “Staggered” without pitch is a recipe for mismatched expectations.

Open Area: The Number That Connects Performance to Cost

Open area is the percentage of the sheet that is “air” due to perforation. It drives:

- airflow and ventilation performance

- acoustic behavior

- filtration throughput

- weight reduction

- sometimes even finishing cost (powder coat coverage and drainage)

If your project depends on performance (CFM targets, sound absorption, pressure drop), ask for open area—or calculate it from hole size and pitch.

Tolerances, Flatness, and Burr Direction (The Stuff That Causes Rework)

Many spec sheets stop at “hole size and pitch,” but professional RFQs include manufacturing realities:

Tolerances

- hole diameter tolerance

- pitch tolerance

- sheet size tolerance

- thickness tolerance (mill tolerances vary by alloy and supplier)

Burr direction

Perforation creates a slight burr on the exit side of the punch. If you’re handling the sheet, laminating it, or using it as a visible architectural surface, specify:

- burr side preference

- deburring requirement (if needed)

Flatness and leveling

Perforation introduces stress. If you require tight flatness for laser cutting, framing, or cosmetic panels, note the flatness expectations up front.

A Quick “Spec Sheet Checklist” for New Buyers

Before you send an RFQ, confirm your spec includes:

- Sheet size (W × L) and whether it’s overall size or perforated field

- Base metal thickness (in or mm)

- Material grade + finish

- Hole diameter (Ø)

- Pitch definition (center-to-center)

- Pattern type (straight or staggered)

- Edge margins (side and end, with dimensions)

- Open area target (if performance-driven)

- Tolerances and any burr/deburring requirements

Final Tip: When in Doubt, Use a Simple Callout Format

If you want a clean, universally understood way to write a round perforated spec, a practical format looks like:

- Material / grade / finish

- Thickness

- Hole Ø

- Pitch (center-to-center) + pattern (straight or staggered)

- Sheet size

- Margins (side/end)

- Tolerances / secondary requirements

It’s not about making the document longer—it’s about making it unambiguous. Clear specs protect your schedule, your budget, and your credibility with production teams.