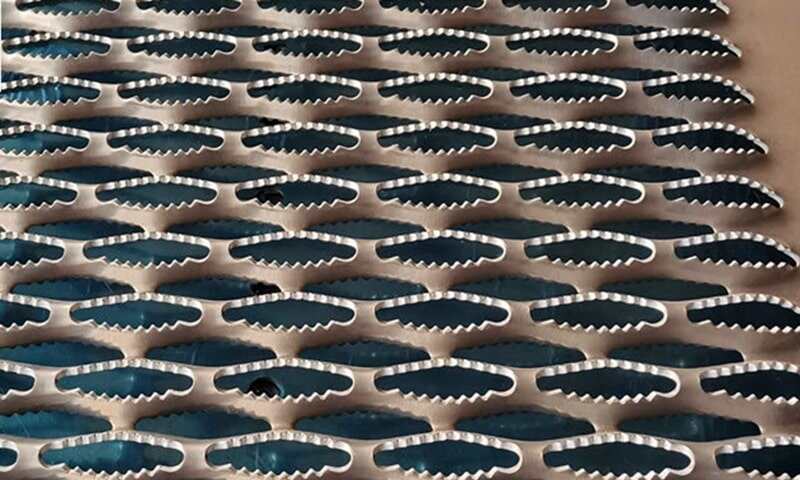

Perforated safety grating is a metal anti-slip tread solution produced by punching or stamping regular patterns of holes through flat sheet plate. The resulting plate is specified for stair treads, platforms, catwalks, ramps and other industrial walking surfaces where slip resistance, drainage, and debris shedding are priorities. Typical hole geometries include round (fish-eye), oval, and elongated slots; pattern selection affects traction, open area, and load distribution.

Key Design Features and Performance Parameters

Pattern and Open Area

The punched pattern determines the open area percentage — a higher open area improves drainage and reduces clogging but can reduce effective bearing area. Engineers must balance drainage and load capacity when choosing a pattern.

Slip Resistance (Surface Traction)

Slip resistance is affected by hole shape, edge burrs, serrated edges, and the finished surface. For applications exposed to oils, liquids, or condensation, specify a pattern and finish that maintain coefficient of friction under expected contaminants.

Structural Capacity

Perforated plates carry load differently from expanded or welded bar gratings. Evaluate bearing span, thickness, and support spacing to ensure the load-bearing capacity meets live and concentrated load requirements for stairs, platforms, and service walkways.

Corrosion Protection & Finishes

Common finishes include hot-dip galvanizing, mechanical galvanizing, mill finish aluminum, and stainless steel passivation. Select metal and finish based on environmental exposure (chemical, marine, indoor/outdoor) and maintenance access.

Common Materials and Typical Specifications

Carbon Steel

Used for high-load, cost-sensitive projects. Often supplied with hot-dip galvanizing for exterior durability. Requires inspection for coating continuity at punched edges.

Stainless Steel (304 / 316)

Stainless steel grades are selected for corrosive or hygienic environments. 316 is preferred for marine or chloride-rich atmospheres. Stainless offers superior long-term corrosion performance with low maintenance.

Aluminum

Chosen where weight reduction and non-magnetic properties are required. Verify alloy temper and thickness to ensure necessary stiffness and bearing strength.

Typical Applications and Mounting Methods

- Stair treads: used as anti-slip plates on industrial stair runs; often mounted to stringers with countersunk fasteners or welded clips.

- Walkways & catwalks: continuous panels installed over structural members; allow runoff and debris through the open area.

- Platforms & mezzanines: larger panel sizes reduce seams and improve load distribution.

- Ramps & loading areas: choose patterns offering better traction under wet or oily conditions.

Installation methods include through-bolting, welded tabs, and adjustable clip systems. Provide clear details for splice joints, end supports, and anti-vibration fastening.

Selection Criteria: How Engineers and Buyers Choose

Duty Cycle & Loads

Define maximum expected live loads, point loads from equipment, and impact conditions. Use load tables from the supplier or perform simple span/deflection calculations for the chosen thickness and support spacing.

Environment & Corrosion

Match material and finish to exposure — interior dry, humid, chemical, or marine. For aggressive environments, insist on stainless steel 316 or robust coating systems.

Serviceability & Maintenance

Consider accessibility for cleaning, how debris will pass through the open area, and whether the pattern will allow pressure-washing or degreasing operations.

Compatibility with Codes and Standards

Confirm local building and safety codes, and verify requirements for tread nosing, edge protection, and handrail integration. While not a replacement for project-specific engineering, industry references such as OSHA/IBC may inform design constraints.

Installation and Inspection Best Practices

- Verify panel flatness and check for excessive burrs or deformation after punching.

- Ensure proper edge support — unsupported overhangs reduce allowable load.

- Use appropriate fasteners (e.g., stainless or hot-dip galvanized) and avoid dissimilar metal contact that could cause galvanic corrosion.

- After installation, document as-built panel orientations, fastener types, and finish notes for future maintenance.

Safety, Compliance and Testing Considerations

- Where applicable, test installed surfaces for slip resistance under representative contaminants.

- Specify anti-slip certifications or lab test results if required by the owner or project standards.

- Consider secondary measures — welded serrations, bonded grit, or raised perimeters — only when compatible with cleaning and load needs.

Procurement Checklist for Contractors and Purchasing Teams

- Confirm exact material (e.g., carbon steel grade, SS grade, aluminum alloy) and finish.

- Provide pattern drawing (punch layout and open area %) and plate thickness and nominal dimensions.

- Clarify edge treatment (beveled, hemmed, or cut) and whether edges require additional reinforcement.

- Ask for load tables or engineering guidance from the supplier for your specified spans.

- Request sample panels or close-up photos to verify pattern and finish before production.

Quick Comparison: When to Specify Perforated Plate vs. Alternatives

Perforated plate is preferred when you need a solid bearing surface with drainage and small-particle retention, whereas expanded metal or bar grating might be selected for heavier structural spans or larger open area requirements.

Conclusion and Practical Recommendation

For industrial stair treads and walking surfaces that require a balance of anti-slip performance, drainage, and bearing capacity, perforated safety grating offers a versatile, customizable solution. When specifying, document loads, environmental exposure, desired pattern/open area, and finish. Engage the fabricator early for load guidance and panel layout to avoid field modifications.