What “getting slippery” actually means in the field

Surface glazing and contaminant films

A thin film of oil, grease, or fine particulates can bond to metal surfaces and create a low-friction layer; under repeated foot traffic the film can reorganize into a smooth, continuous “glaze” that reduces micro-scale roughness and lowers traction. This is most common where frequent light spills combine with infrequent degreasing.

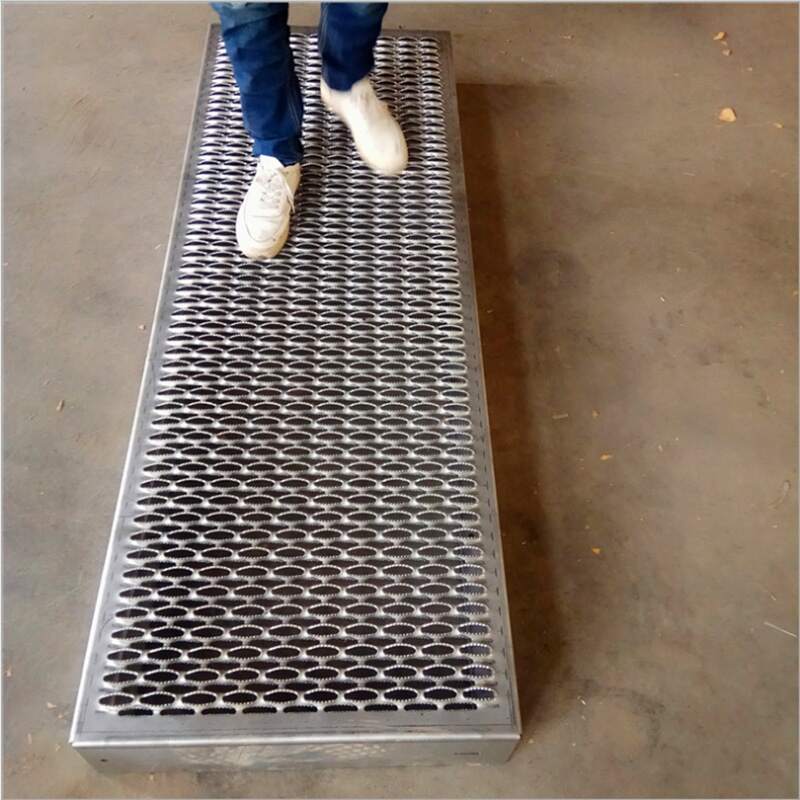

Loss of macro-texture from wear and polishing

Raised serrations, serrated perforations, or raised beads designed to provide bite wear down over time. Hard shoe soles or wheeled traffic can polish high points until the macro-texture no longer interrupts the sole — a mechanical, cumulative process rather than a sudden failure.

Clogging and reduced drainage

Perforations, serrations or open grating are only effective if they remain clear. Accumulation of sediment, fibrous debris, or paint overspray seals perforations, allowing puddles and contaminant films to persist. Even small reductions in open area can change surface hydrodynamics and increase dwell time for liquids.

Corrosion, coatings breakdown, and micro-smoothness

Rust and salt deposits can paradoxically create slick surfaces where corrosion products mechanically abrade the texture or where loss of protective coating exposes shiny base metal. Similarly, degraded or incompatible coatings can form smooth layers that reduce friction.

Thermal and deformation effects that change contact geometry

Buckling, sagging or thermal expansion that flattens an originally profiled surface reduces the effective bite. Where grating is fixed at only a few points, cyclic loading can open micro-gaps that let dirt accumulate in the walking line.

Human and operational factors that accelerate slipperiness

Changes in footwear and traffic type

A switch from soft-soled footwear to harder, smooth soles or an increase in wheeled trolleys will change how the surface performs; a surface that was adequate for one traffic profile may underperform for another.

Cleaning practice and chemical use

Infrequent cleaning allows build-up; inappropriate cleaners (e.g., some silicone-based maintenance sprays) can leave films that reduce traction. Conversely, overly aggressive cleaning without re-profiling can remove engineered roughness.

Inspection & engineering decision points

Quick field checks that indicate a problem

Look for: persistent pooling in the same locations after a heavy wash; visible polishing of high points in the walking band; repeat slip incidents concentrated on particular spans; and clear sealing of perforations with fine silt or paint. These are signals that cleaning alone may not be sufficient.

When to escalate from cleaning to refurbishment

If routine degreasing and mechanical clearing of perforations restores friction for only a short time (a handful of cleaning cycles) — or if there is visible mechanical polish across the dominant pedestrian line — plan a refurbishment. Refurbishment options include grit blasting to re-establish texture, partial replacement of heavily worn panels, or adding engineered anti-slip overlays where drainage and load allow.

When replacement is the correct engineering choice

If load-bearing capacity, corrosion damage, or core geometry has changed (e.g., sagging that traps liquid), replacement is often more cost-effective than repeated maintenance. For many industrial platforms, specifying a replacement with engineered open-area geometry and permanent anti-slip features reduces lifecycle cleaning costs and EHS incidents. Consider retrofit options such as a perforated grating with optimized open area and edge profile perforated metal grating designed for anti-slip platforms when structural capacity and drainage allow.

Design and procurement considerations for durable traction

Match open area, hole shape and edge profile to contamination type

Large circular holes pass solids better but reduce continuous contact; elongated slots or staggered perforations can balance drainage and tread area. Choose geometries that shed the expected contaminant size and that maintain positive edges under the projected wear life.

Material, finish and coating selection

Stainless grades resist corrosion and maintain profile where chemical exposure is a factor; carbon steel with protective coatings may be acceptable in dry, indoor environments but will need a higher maintenance cadence. When specifying finishes, prefer mechanical texturing (serrations, raised beads) over coatings that rely on surface friction alone.

Supplier capability and lead-time as risk mitigators

Ensure the vendor can supply a range of material thicknesses, punching patterns, and finishing tolerances — this affects ability to match the as-built geometry during retrofit. For a consolidated view of manufacturing capability, material options and typical lead-times consult the manufacturer’s capabilities and material breadth at the site overview: manufacturer capabilities and material breadth.

Practical maintenance checklist and thresholds for action

- Daily/weekly visual checks — pooling, visible glazing, clogging of perforations.

- Monthly hands-on test — simple pendulum or boot-swipe test to confirm traction in critical egress routes (document changes over time).

- Trigger for engineering review — repeated slip near-misses or evidence that cleaning restores traction for less than a defined number of cycles (establish a site-specific cycle count).

- Trigger for refurbishment/replacement — loss of macro-texture across walking band, structural deformation, or failed coatings exposing core metal.

Case-by-case retrofit example (decision flow)

If the cause is mainly contamination and perforations are still open → increase cleaning / add intercept drains.

If perforations are clogged and cleaning is only intermittently effective → plan scheduled blasting and re-establish drainage channels.

If macro-profile is mechanically worn, or corrosion has advanced → specify replacement panels sized to the opening with engineered anti-slip geometry — consider a perforated solution that maintains open area and positive edges for long-term traction. One practical retrofit option is a perforated safety grating with engineered hole pattern and raised edge profile to restore bite and drainage without full structural replacement. See a solution reference here: perforated safety grating for retrofit platforms.

Risk trade-offs and lifecycle view

Short-term: intensive cleaning is cheapest but may only postpone the problem.

Medium-term: surface re-profiling (blasting, re-serration) restores performance but has downtime and recurring costs.

Long-term: replace with an engineered grating matched to contamination profile and traffic — higher capex, lower operational cost and EHS risk.

Summary — actionable next steps for EHS / maintenance

- Record the failure mode (contaminant, wear, drainage, deformation).

- Run a controlled cleaning + test to confirm whether friction can be restored.

- If cleaning is insufficient, plan refurbishment or replacement based on the inspection triggers above.

- When specifying replacement, prioritize hole geometry, edge profile and material suited to the contaminant and traffic, and verify supplier manufacturing breadth and tolerances.