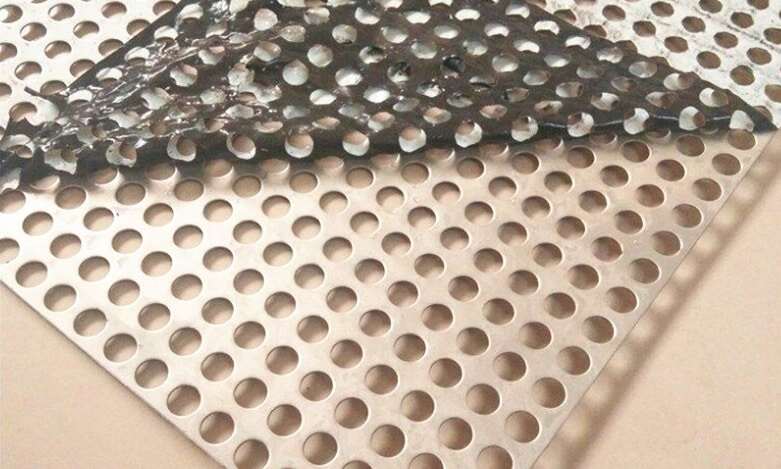

5052 alloy is a common choice when manufacturers and designers need a balance of corrosion resistance, ductility and moderate strength. When the material is supplied as a perforated product, the mechanical behavior changes compared with solid sheet stock. This article compares performance concerns you should expect from a 5052 perforated aluminum plate in typical manufacturing and design scenarios, and it gives practical suggestions for choosing thickness, hole pattern and forming strategy.

Strength: what changes after perforation

Perforation reduces the net cross-section and concentrates stress around hole edges, so the nominal strength of a 5052 perforated aluminum plate is lower than the same alloy in solid form. However, the alloy’s favourable strength-to-weight ratio and resistance to corrosion make it still an attractive option when weight or corrosion are limiting factors.

Practical points:

- Choose a slightly higher thickness or closer pitch if in-service loads are significant.

- Consider hole shape: round holes generally preserve more tensile area than elongated slots under uniaxial load.

- For applications needing higher static strength, compare with our product options like Stainless Steel Perforated Metal Plate and Carbon Steel Perforated Metal Plate to assess trade-offs.

Formability and bending

One of the major advantages of 5052 is its good ductility and formability compared with many higher-strength aluminum alloys. For punched or laser-cut 5052 perforated aluminum plate, formability remains good but requires attention to tooling and bend allowances:

- Use larger bend radii near rows of holes to avoid cracking.

- Orient bends relative to hole rows: bending across short spans of unperforated material gives better results than bending through a dense hole field.

- For deep drawing or complex forming, microperforated patterns behave differently from large-hole patterns — finer perforations can help maintain sheet continuity. Consider our Microperforated Metal Plate for acoustic/ventilation designs that still require forming.

Manufacturing considerations for perforation

Perforation method (mechanical punching vs. laser/nibbling) affects edge quality and residual stresses. For 5052 perforated aluminum plate:

- Mechanical punching is economical for standard patterns and thicker gauges but creates a small hardened edge zone.

- Laser/laser-cut perforation produces cleaner holes and is preferred for thin gauges or stainless finishes.

- Deburring and passivation matter for corrosion-sensitive applications — we can supply deburred, anodized or painted finishes depending on the final use.

Linking to product pages: if you prefer round holes for visual consistency, see Round Hole Perforated Metal Plate; for decorative or high-flow needs, review Hexagonal Hole Perforated Metal Plate or Slot Hole Perforated Metal Plate.

Typical applications and selection tips

Because of its balance of properties, 5052 perforated aluminum plate is well suited for:

- Architectural facades and sunshades (lightweight, corrosion resistant).

- Ventilation grilles and filters (good formability and available in microperforation).

- Marine and coastal equipment where corrosion performance matters.

Selection checklist:

- Define required open area (perforation percentage) and then choose thickness/pattern to keep local stresses acceptable.

- Prototype critical formed parts to verify bend behavior.

- Consult finish and surface treatment options early — anodizing, powder coat, or passivation change performance and appearance.

Conclusion and next steps

In summary, 5052 perforated aluminum plate offers a strong combination of corrosion resistance and formability, but perforation reduces nominal strength and needs careful consideration in design and tooling. For custom sizes, hole types and finishes we support one-piece orders through to large volumes — feel free to contact us at info@perfsheet.com for samples, technical drawings or testing guidance. You can also browse our related products such as Aluminum Perforated Metal Plate, Perforated Safety Grating, and Microperforated Metal Plate for matched options.