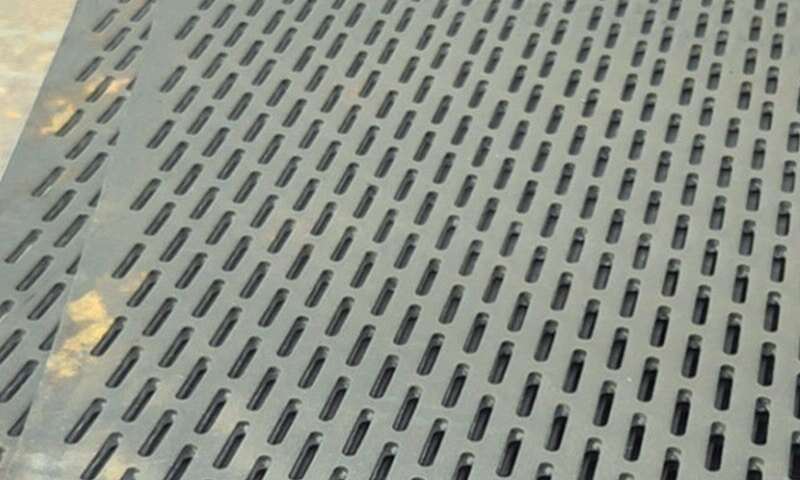

In industrial ventilation, filtration, and acoustic control systems, the long slotted perforated metal sheet plays a vital role in managing airflow distribution. Compared with other perforation types such as round hole perforated metal sheets or hexagonal perforated sheets, the elongated slot shape allows air to pass through in a more directional and uniform pattern. This distinctive geometry reduces turbulence and helps engineers achieve more efficient flow control across large surface areas.

The long slot openings create continuous linear channels that guide air movement smoothly. This makes them ideal for applications in air diffusers, drying systems, speaker panels, and industrial enclosures where both mechanical strength and precise air regulation are required.

The Principle Behind the Airflow Distribution

The principle of airflow distribution in a long slotted perforated metal sheet is based on the interaction between hole geometry, open area ratio, and sheet thickness. When air passes through the slots, it accelerates and expands evenly on the other side, forming a controlled laminar flow.

By adjusting parameters such as hole length, width, pitch distance, and open area percentage, manufacturers can fine-tune the airflow characteristics to meet specific design needs. For instance, a higher open area results in lower pressure loss, while narrower slots enhance diffusion and noise attenuation.

This adaptability is one of the key reasons why many industrial designers prefer slotted perforation patterns over traditional round holes in systems requiring directional airflow.

Advantages of Using Long Slotted Perforated Metal Sheets

Beyond the airflow benefits, the long slotted perforated metal sheet provides excellent durability and versatility. It can be fabricated from a variety of materials such as carbon steel perforated metal sheet, galvanized perforated metal sheet, aluminum perforated sheet, and stainless steel perforated metal sheet.

Each material type offers its own advantages—carbon steel for strength, aluminum for lightweight applications, and stainless steel for corrosion resistance. With proper surface treatment, such as powder coating or galvanizing, these sheets can be used in both indoor and outdoor environments.

Moreover, the long slot pattern also provides an attractive visual design, making it suitable for architectural façades, ceilings, and protective screens where aesthetics and performance go hand in hand.

Customization Options to Meet Specific Project Requirements

One of the most significant advantages of choosing our factory in China is the ability to customize every aspect of the perforated sheet. We manufacture long slotted perforated metal sheets in various sizes, thicknesses, materials, and perforation patterns according to customer specifications.

Whether you need a single prototype or bulk production, we provide full customization to match your design drawings or performance requirements. In addition, our advanced CNC punching technology ensures precise hole alignment and consistent quality in every piece.

If your project demands other perforation shapes, you can also explore our round hole perforated metal sheet, square hole perforated sheet, micro perforated sheet, or perforated safety grating to find the perfect fit for your engineering or architectural design.

Conclusion

The long slotted perforated metal sheet offers a unique combination of controlled airflow, structural integrity, and aesthetic appeal. Its ability to regulate air velocity and direction makes it a preferred choice for engineers and designers working in ventilation, filtration, and architectural applications.

By understanding the airflow distribution principle and selecting the right perforation pattern, you can significantly improve system performance and efficiency. For more details or custom solutions, feel free to contact us at info@perfsheet.com — our technical team is ready to assist with design optimization and manufacturing support.